Industry 4.0 harnesses data from all the machines, devices and sensors in any manufacturing operation and enables them to communicate with each other via the Internet to make informed and timely decisions.

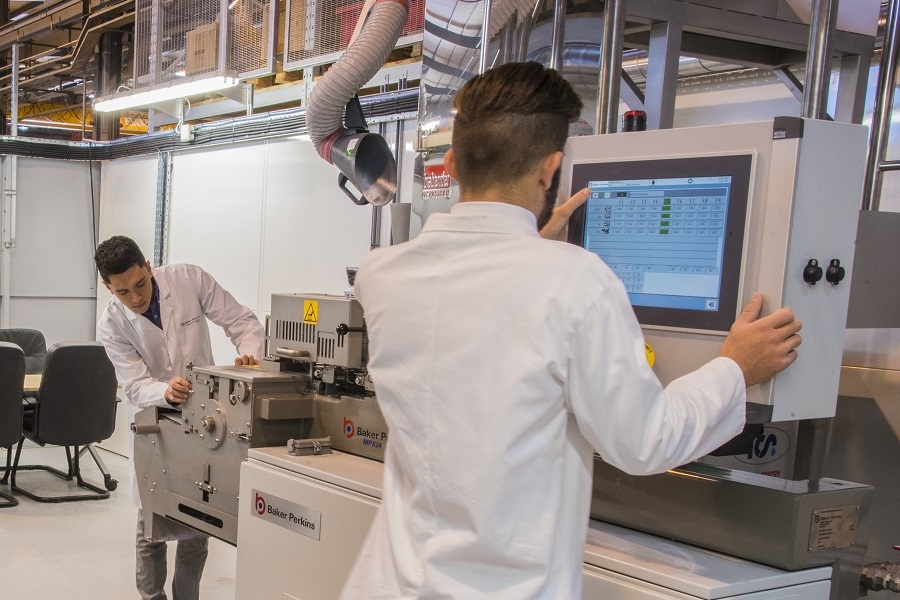

Baker Perkins can provide its machines ‘Industry 4.0 Ready’ to a level that allows interconnection with other systems via the Internet. The key unit is an eWON Flexy Gateway – a modular router and data gateway allowing linkage to remote devices with benefits based around data acquisition, handling and transmission.

Baker Perkins machines are Internet 4.0 ready. The eWON Flexy Gateway modular router and data gateway allows linkage to remote devices with benefits based around data acquisition, handling and transmission.

All systems will now sample and upload all data from the process equipment to a secure cloud or server, where it will be available to facilitate improved decision making. The major advantage with simpler control systems is that analysis is being carried out on the process as a whole, rather than discrete sections.

Real time OEE (Overall Equipment Effectiveness), trending and basic maintenance are all included.

Innovative features include a unique Baker Perkins machine centre-lining system allowing operating parameters to be compared with previous settings, and alerting supervisors to potential problems caused either by operator changes or impending equipment failure.

The next step in the development of Industry 4.0 will allow Baker Perkins to predict when key components need replacement.

Intelligent analysis of process performance and machine condition will enable timely advice to be provided on potential machine problems or service and parts requirements, before they cause costly downtime.

Performance optimisation based on comparisons with similar machines will also be possible. The eWON Flexy modular router and data gateway has been used for some time by Baker Perkins to dial into customer’s control systems anywhere in the world when they call for remote support. It has also been used in the remote commissioning from the UK of a new extruder in India.