The circular economy model has been a buzzword in the plastics industry for several years now as the industry realises that it’s time to rethink how plastics is produced, used and disposed. Beyond the current take-make-waste extractive industrial model, a circular economy aims to redefine growth, focusing on positive society-wide benefits.

The Ellen MacArthur Foundation states that the circular economy model entails gradually decoupling economic activity from the consumption of finite resources, and designing waste out of the system. Simply put, the model underpins a transition to renewable energy sources and is based on these three principles: design out waste and pollution; keep products and materials in use; and regenerate natural systems. Major industry players have joined various initiatives to promote production processes that will lead toward a circular economy.

Southeast Asia has been battling the plastic waste problem, as four countries in the region - Indonesia, the Philippines, Vietnam and Thailand – along with China, contribute to half of the world’s plastic waste entering the oceans and killing marine life. Members of the Association of Southeast Asian Nations (ASEAN) signed a joint declaration in June 2019 where its members pledged to take actions to significantly reduce marine waste.

Game-changing technologies for circularity

Noting how Southeast Asian countries have embarked on a quest to alleviate the plastic waste problem, the objective of attaining a circular economy has become a priority among plastics manufacturers in the region. Thus, the plastics industry has been exploring the latest technologies, production processes and material solutions that will enable plastics recycling and processing of recycled materials into new products. With the COVID-19 pandemic, the large volume of plastic waste has put the plastic industry to work double time to implement recycling and effective waste management.

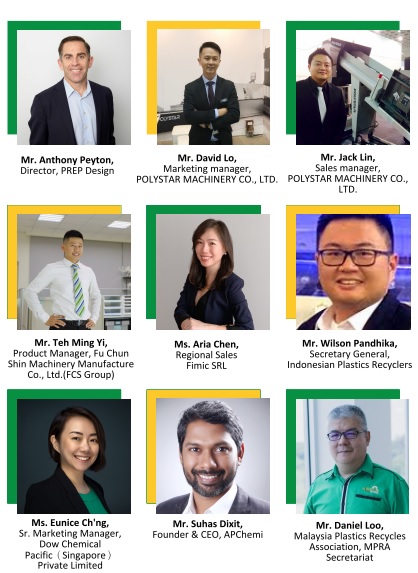

The “ASEAN Manufacturing Summit: Creating a Circular Economy for Plastic”, a virtual event organised by Ringier Events on 3 December 2020, brought into focus the various innovations to support the industry’s move to achieve a circular economy. The presentations by industry experts are all aimed to provide those engaged in plastics production with relevant information on the market for recycled packaging, environment-friendly injection moulding, high performance materials from recycled plastics, advanced recycling system, and components to aid sustainable recycling.

The lineup of guest speakers came from various countries, thus providing diverse views and informative discussions on the different aspects of production and how these can contribute to meet the circular economy targets.

Mr. Anthony Peyton, Director of PREP Design, identified the key aspects of designing recyclable packaging for each market. PREP Design Pty Ltd was founded in 2017 by GreenChip, Planet Ark Environmental Foundation and Innovyz Waste & Recycling Technologies to expand the adoption of PREP, a software that simulates consumer packaging's journey, once discarded for recycling at kerbside, and is the only tool providing immediate feedback to designers advising why packaging is not recyclable.

Advanced injection moulding systems for green production, a topic that was presented by Mr. Teh Ming Yi, Product Manager, Fu Chun Shin Machinery Manufacture Co., Ltd. (FCS Group), provided attendees with an overview of how injection moulding systems can be designed and engineered to adhere to the circular economy targets. Mr. Teh discussed the recycling of PET bottles to produce PET sheets, resins and PP pallets, and processing of re-compounded or environment-friendly materials. He also gave an overview of the FCS intelligent manufacturing system - the iMF4.0,

The sustainable journey of DOW was presented by Ms. Eunice Ch’ng, Senior, Marketing Manager at Dow Chemical Pacific (Singapore) Private Limited. As Ms. Ch’ng explained, DOW’s commitment to sustainability dates back to over two decades ago. The company launched the first set of goals in 1996, and the second set followed in 2005. DOW recently launched its updated targets building on Sustainability Goals 2025 - the third set of goals launched four years ago - to advance circular economy and climate protection. The presentation focused on DOW’s latest sustainability efforts in Asia – including the launch of the first Post-Consumer Recycled (PCR) Resin, and the incorporation of bio-based polyethylene in industrial packaging application through collaboration with a strategic customer.

Recycling made simple took centre stage in the presentation from Polystar Machinery Co., Ltd. with Mr. Jack Lin, Sales Manager and Mr. David Lo, Marketing Manager, explaining how customers can achieve highly-efficient recycling with less waste but with greater value. Polystar Machinery’s Repro-FLEX, in particular, boasts of simple design and flexible operation, and ideal for the reprocessing of polyethylene (HDPE,LDPE, LLDPE) and PP polypropylene flexible packaging material, printed and non-printed. This cutter integrated pelletising system eliminates the need of pre-cutting the material, requires less space and energy consumption while producing high quality plastic pellets at a highly productive rate.

In recycling contaminated plastic, the advantages of an automatic melt filter were of importance and these were fully emphasized by Ms. Aria Chen, Regional Sales Manager at FIMIC Srl. As Ms. Chen explained, in post-consumer waste recycling, filtration plays an important role and FIMIC Italy has provided hundreds of automatic and continuous melt filters to plastic recyclers worldwide. FIMIC automatic filter can process waste contaminated with paper, wood, aluminium, small metal pieces, unmelted plastics, rubber, etc. The automatic melt filters also feature self-cleaning function to remove the contamination on the screen automatically and fast,

Sustainable chemical recycling of toughest and dirtiest plastic waste was discussed by Mr. Suhas Dixit, Founder & CEO of APChemi. APChemi offers proven, patented and robust pyrolysis plants for converting waste plastic, tyre and biomass into fuels. APChemi technology has the capability to process toughest and dirtiest plastics including post-consumer multilayer packaging waste and polyethylene terephthalate (PET or PETE).

Another highlight of the virtual event was the Expert Views where representatives from industry associations shared their insights on plastics recycling trends in Southeast Asia. Mr. Wilson Pandhika, Secretary General of Indonesian Plastics Recyclers (IPR), provided an overview on how Indonesian recyclers are meeting today’s quest for a circular economy. Mr. Daniel Loo, representing the Secretariat of the Malaysia Plastics Recycles Association (MPRA), shared how Malaysia has been working to achieve systematic and efficient recycling to meet today’s trends. The event attendees were provided with opportunities to ask questions during the summit, as well as arrange one-on-one virtual meetings with the participating companies. IRNA