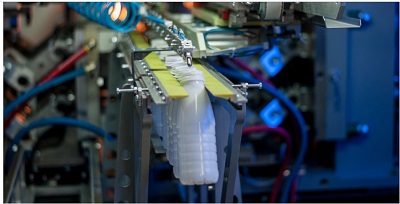

PET Technologies has recently brought to the market a new generation of flexible PET stretch blow moulding machines APF-Max. Its output varies between 3000 and 14 000 bph, while the bottle volume is between 0.1 and 8 L. The product range includes 6 basic models and 5 extra. First customers have already highlighted its features.

User-friendly concept and innovative design marks the new machine which also features streamlined form and alternative colouring, modular concept and controller that makes it easy to operate. Worth to highlight that all the communications are connected via the top of the machine. The electric cabinet is backside. The machine is divided into 2 parts to transport it easily by land or by sea.

APF-Max blow moulder is equipped with B&R PLC (since 2017, B&R is part of ABB group). The program, as well as the manuals for the machine, are available in languages depending on the customer’s location. Central lubrication system makes machine maintenance easier.

Flexibility for enhanced performance

The APF-Max series has 2-, 3-, 4-, 6-, 8-cavities configurations. The notion of “flexibility” in terms of APF-Max series by PET Technologies stands for several aspects. First is the wide range of preform neck standards. With the same machine, it is possible to produce both 100 ml bottles for sanitizers, for example, and 1 L wide neck jars for coffee.

Another aspect is the increase of output of the blow moulder. The customer can buy 4-cavity model with output 7000 bph and then reach 14000 bph. It is enough to install additional cavities in order to make respective changes in the heater.

The APF-Max series also enables the production of wide range of bottle formats, from 100 ml up to 8 L. For model APF-Max 3U, it is possible to produce up to 2 L bottles, the machine has 3 cavities. When deciding to switch to 2 gallon bottle, the machine is readjusted. For hot fill option, this is applicable to the whole APF-Max series and is an additional advantage to the other features earlier described.

APF-Max blow moulder flexibility keeps pace with quick-change system. The equipment concept allows the use of many mould sets for wide range of PET bottles with minimum change over time. Blow mould is equipped with non-spill quick-change connections and is replaced in one piece. Thus, 15 minutes are enough to change the blow mould and start to produce another bottle format. 108 mandrels in the heater of 8-cavity blow moulder you can change in just 4 minutes.

The all-electric configuration is another advantage. The servo drives provide more precise positioning together with high speed, stable heater conveyor speed and blowing process. The stretching rod position is automatically controlled depending on the bottle height when you switch from one bottle format to another. Preblow is also controlled via PLC.

NIR heating and low total installed power. APF-Max blow moulder is equipped with the special short-wave near infrared heating system (NIR). It is not a common method for PET blow moulding market, though preform heating is more efficient whilst less kilowatts are consumed. The advantages of NIR heating system for PET bottles production include: uniform temperature distribution between the inner and outer parts of preform wall; reduced heating time; compact heater size; reduced energy consumption of blow moulder; ceramic reflectors are used for better preform heating and to reduce energy consumption. Automatic temperature regulation is on the top of the story.

The APF-Max series is also universal and operator-friendly, aside from being economic and flexible. These are only few attributes to characterise the new generation of PET stretch blow moulders APF-Max. The machine has high output while its dimensions are more compact. It is equipped with double air recovery system to cover the demand of low pressure and pressure for preblow.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login