The shift to a healthier lifestyle around the world is pushing up interest in over-the-counter confectionery for health and medical use, with nutritional supplements in candy format leading the way and remaining very popular for use by children. But besides vitamin candies, lozenges, jelly-type medication and fruit gums for pain relief or headaches are increasingly becoming popular as nutritional supplements or nutraceuticals, itself a growing market as more people start looking after their health, especially with the pandemic.

Winkler und Dünnebier Süßwarenmaschinen GmbH (WDS), a leading global manufacturer of confectionery machines, draws upon its expertise in moulding plants, to offer OTC variants across its main product and machine categories, from hard candies to jellies and even chocolates. The company has the capability to handle the entire range of deposited sweets with different applications and throughputs, with complete development of individual OTC sweets with exact dosage of active ingredients. The Germany-based firm can also tailor production processes and ensures GMP-compliant design.

![]() “We see a huge growth potential in this market and, with our technology and experience, are equipped to serve the growing demand for both traditional confectionery and OTC-type products,” said Waldemar Heinrich, Area Sales Manager at WDS, whose responsibility covers South East Asia and Eastern Europe.

“We see a huge growth potential in this market and, with our technology and experience, are equipped to serve the growing demand for both traditional confectionery and OTC-type products,” said Waldemar Heinrich, Area Sales Manager at WDS, whose responsibility covers South East Asia and Eastern Europe.

Waldermar Heinrich, Area Sales Manager, WDS

As supply and variety of health products grow amid the health and wellness trend, demand for new delivery formats also rises, in particular among the younger generation. This applies not only to vitamins but also to medicines for pain relief and even products for anti-aging and skin care.

“We also see rising demand for high-protein, THC/cannabis-infused medicated products. WDS is keen to serve these sectors with the right technologies,” he said.

Southeast Asia a sunrise market for WDS

More consumers are turning to OTC confectionery for a more enjoyable and convenient way of taking supplements or medicines. WDS sees the market for such products growing in Southeast Asia, where demand for both traditional starch moguls and starchless lines is rising.

“A growing number of our customers are asking about expertise and equipment to serve the growing demand for both traditional confectionery and OTC-type products. Younger consumers, in particular, are looking for new delivery formats of products for their healthy lifestyle, and not vitamins but also products for pain relief and personal skin care,” he said.

Full-solution partner

Recognised as “the home of confectionery diversity,” WDS can work with manufacturers to produce a diverse range of OTC sweets.

"Jellies, however, appear to be most attractive for many customers,” Mr Heinrich said.

WDS uses its starchless technologies with silicone and/or polycarbonate moulds to produce jellies for OTC purposes. This process requires depositing the mass on the final solids. As every WDS line has various settings, the company can control tailing and therefore achieve precise depositing weights for high quality.

The company can also collaborate with manufacturers for OTC product conceptualisation and development, including design, dosage, taste and aroma, to planning, manufacturing, commissioning of customized production systems through after-sales. Its confectionery experts can conduct a thorough study on the product idea and recommend a mix of ingredients depending on the benefit claim the customer wants to achieve. Comprehensive product tests can be done at the company's Product Innovation Centre located in its headquarters in Germany.

The ConfecECO line adopts a modular design to allow flexibility and future upgrades, supports three possible stages of extension.

“We will evaluate all important process steps such as depositing temperature and test for which depositor setup works best and what is the necessary cooling time,” he said.

The tests also serve as basis for the company's in-house engineering, automation and fabrication of the lines, which are always tailored to customer needs.

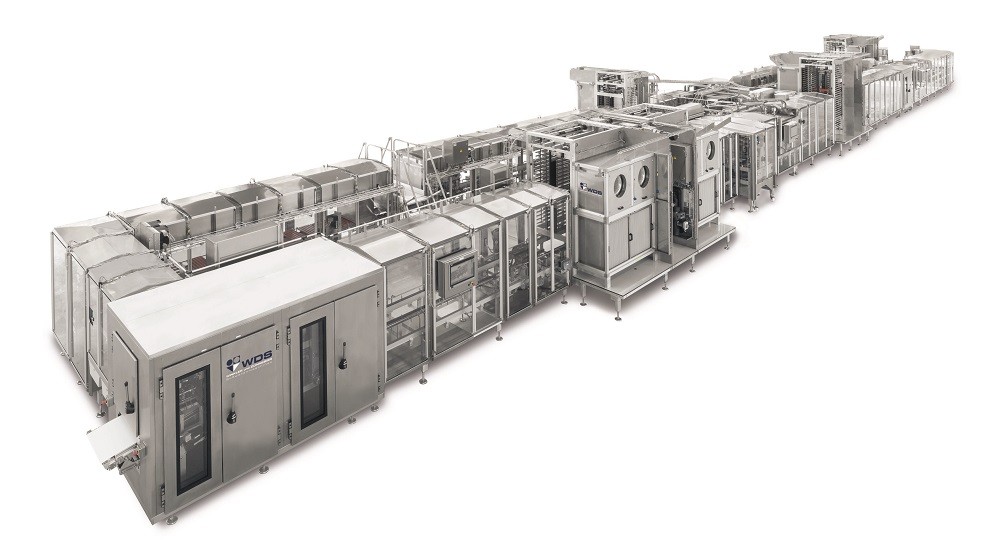

WDS can accommodate a wide range of production capacity in its lines. Its ConfecECO line, designed for growing businesses and artisans, can serve entry-level capacity requirements at approximately 400kg/h. The line, which adopts a modular design to allow flexibility and future upgrades, supports three possible stages of extension: automated mass depositing followed by an automated cooling process up to a complete manufacturing plant with product demoulding unit.

For greater capacity demands, WDS offers the ConfecPRO machine series, which can support more than 400kg/h. Designed for depositing medium to large capacities of filled and solid chocolates, the ConfecPRO also boasts a modular and highly flexible design for one or two lanes and at ground level or several floors. It is easily installed on-site and expandable with its decentralised control principle and modular components. The ConfecPRO also boasts high depositing accuracy and almost unlimited process monitoring.

The ConfecPRO machine series is for depositing medium to large capacities of filled and solid chocolates.

WDS adopts the principle of loose moulds in all its production lines. This allows the company to lift, pick and handle the moulds easily. If a vision system, for instance, detects a polluted mould within the line, this mould can be replaced easily without impacting the speed and performance of the line.

All of the company's lines can be ordered with automatic mould exchange, automatic mould spraying, depositing, cooling, demoulding and the necessary coating equipment for final finish.

“As a full-solution partner, we also service all our lines with our technicians, with 24/7 remote support and when upgrades or maintenance are necessary,” Mr Heinrich added.

Addressing overdosage, ensuring quality

Supplements require special ingredients that are costly. As the ingredients are added to a hot slurry, overdosaging usually happens to achieve the target nutritional value.

WDS has been developing and implementing process solutions aimed at reducing the need for overdosage. One of these solutions is the WDS Smart Pipe, which is used in conjunction with a continuous mass cooking process.

This setup shortens the residual time of the supplements in the heated mass before depositing into the mould cavities to only about 30 seconds. In addition, the mould is directly transferred into a cooler within less than a minute to reduce the product’s core temperature.

Both steps help reduce overdosage, in turn leading to greater cost savings and less wastage of resources.

Reducing – or totally eliminating -- starch is another concern. WDS has worked with partner companies to develop a starch-free fruit gum production through the Fast Forward Process. This concept enables hygienic fruit gum production without starch powder using conventional or commercial gelatine. Whilst the gelatine provides the texture and haptics, the packaging helps with the final form. Packaging can be in the form of bags, bottles, glow packs or blisters using Made in Pack application.

WDS uses reusable silicone moulds instead of traditional starch trays. Besides reducing handling compared to the traditional process, FFP eliminates dust, residues and cross contamination resulting from the use of starch.

The FFP also cuts production time and overall manufacturing costs as it saves on production space, energy and manpower.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login