FORTY-SEVEN years of experience places Betagro Group among Thailand’s major agro-business companies. The first Thai manufacturer to apply e-traceability, Betagro has set its own benchmark, on top of other international standards, for product quality and safety in all its processes. In this interview, assistant vice president Sahas Ratanasoponchai talks about these efforts.

Betagro started as a feed mill in 1967 and has had a natural progression to its business.

Yes, in the last 47 years Betagro has grown into a fully integrated agro-industry that caters to the local and the international markets. We have 5 Core Business Units: One is Poultry Integration Business including feed mill plant, Hatchery, Parent stock farm, Broiler farm, slaughterhouse and further processing plant; The second is Swine Integrated Business including feed mill plant, Grand Parent, Parent Stock, and fattening farm, a modern slaughterhouse and further processing plant; The third is the Regional and Feed business of which we have about 70 branches and nine feed mill plants in Thailand. The fourth is Animal Health Business. Incidentally we have the biggest and most modern animal health product manufacturing plant in Thailand located in Lopburi province. The last is our Food Business including a sausage plant, restaurants and retail shops.

The company has also invested heavily in neighboring countries, which makes you well positioned for the Asean Economic Community. What is the current capacity in each country?

Our initial capital spending in our feed mill plant in Cambodia was about US$30 million. Capacity is about 18,000 tons per month. We also have a parent stock farm for swine there of about 1,500 sows. Our investment in Laos is for a parent stock swine farm of around 900 sows.

Betagro assistant vice president Sahas Ratanasoponchai

How do you ensure food safety at Betagro? Are there international systems in place?

Betagro’s vision is to develop and produce quality, safe and nutritious food products for consumers worldwide. This has led our company to produce safe and high-quality food using the same quality standards for both our local and export markets.

We comply with international standards such as the British Retail Consortium (BRC), International Food Safety (IFS), ISO22000, Hazard Analysis and Critical Control Point (HACCP), Good Manufacturing Practices (GMP), Allergen Control Plan (ACP). In addition, we created our own food safety standard called Betagro Quality Management or BQM to provide complete assurance 24/7 and not just rely on third-party audits, which are announced and done on a yearly basis.

Quality systems are therefore enforced round the clock instead of only when third-party audits are announced to be carried out?

That is correct. The Betagro Quality Management Mark (BQM) is a unique concept that not only places food safety and eating enjoyment at the core of our activity but provides our customers with the daily assurance that we will consistently achieve their service targets and expectations.

Awareness of the vital importance of safe food manufacturing is instilled in all Betagro staff, at all levels, at all farms, factories and facilities, instilling a sense of responsibility toward the health and welfare of consumers. This is achieved through ongoing training programmes and continuous development of operational procedures.

Betagro is also the first company in Thailand to use e-traceability. Please tell us about the investment in Betagro Enterprised Traceability (BET).

E-Traceability is one of our food safety programs, and Betagro started developing it in 2003 with Thai software company FXA, which now goes by the name Oppsmart. We continue to work together to maintain and update the software. We pay roughly US$300,000 per year for all business models.

The main idea was to establish a computerised trace back system that could track each step of production so that when faced with any food safety risks, we could quickly respond and effectively manage them.

Secondly we wanted to align standard work procedure in food processing to enhance food safety. We also wanted to build the planning and monitoring database to boost the supply integration management’s efficiency and productivity.

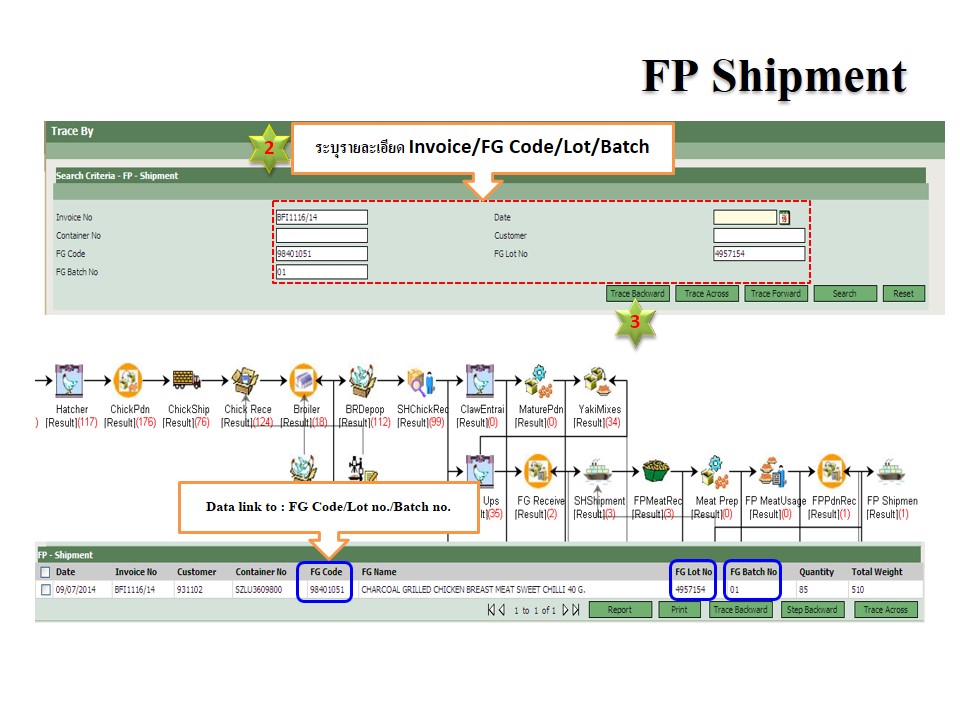

Once an invoice number and relevant codes are keyed into the Betagro Enterprised Traceability (BET) system, it only takes two to three minutes to retrieve all supply chain data

How does the system work to ensure food safety?

The information in the database itself contains all the production parameters. We provide username/password for each customer then he/she inputs the product code and invoice number/batch number to track shipment all the way back to the breeder farm. Our customers can retrieve all other pertinent information including breeder farm, hatching house, feed plant, vaccine and fresh meat manufacturing factory, results of inspection–all in two to three minutes. Prior to having this system, it took two weeks or more to get all this information to the customer. We also use geographic information systems (GIS) mapping in our e-trace to show exact farm locations. Initially, the trace online only worked with business-to-business, but now we have developed QR codes for consumers to trace back our product via mobile phone. To ensure that the traceability information is kept current, all production lines input data on a daily basis then the person in-charge of each production unit carries the trace exercise to ensure that tracing for the whole integrated chain runs smoothly. It is almost real-time. Accuracy and security of data were priorities in setting access control for the system. Only authorized persons from each business unit are given access, but we share information across business units and use them to improve our productivity.

What fine-tunings, if any, have been done to the system since its launch?

It took three years to test run the system. We needed to ensure that data inputting was done correctly to prevent system error. Some tweaking also had to be made to ensure all pieces of traceability data were pieced together accurately to show the big picture.

What food products is the system currently used for?

The system was implemented in phases starting with our poultry production line, then swine integration, and now even in our sausage business and egg packing house.

Does the system work with other standard technologies?

The system or tools that we use are Internal Bar Code, GS1 Bar Code, RFID and GPS.

They work well with mobile phones, both Android and iPhone.

The system was initially introduced in Spy on Me kiosks that were set up in malls but these have been discontinued.

The kiosks have been replaced with QR codes, which consumers prefer to trace on their mobile phones. These are much easier to operate compared to kiosks, which are dependent on the Internet and Wi-fi connections of a particular location. The information from our BET is exported to QR Codes.

In June 2012, we migrated to using QR codes for the domestic market and in November 2013 entered into a co-branding traceability agreement with TESCO Lotus using QR codes.

What are Betagro’s main markets for its product lines?

Our main markets are meat and further (processing) products but we are now moving into foodservice such as restaurants. For exports, the EU and Japan remain big markets.

Part of your company CSR is the Quality Kitchens Project. Could you tell us how it is being implemented?

It is our CEO’s vision to help stakeholders and upgrade their food safety system. To give back to the communities where Betagro factories are located, the Quality Kitchens project was initiated to improve the quality standards of school kitchens, with emphasis on hygiene and cleanliness, as well as to promote food safety awareness in nearby communities. In the initial phase, the Quality Kitchens project was introduced to a total of 40 targeted schools in Pattananikom and Chaibadan districts, Lop Buri province, and in Pakchong district, Nakorn Ratchasima province. The project includes education and consultation on food safety, kitchen hygiene as well as financial support for each school to improve their kitchen to the required standards. In addition, training sessions related to food safety are regularly provided to further cultivate awareness of good kitchen practices amongst students and teachers, and encourage them to pass on their knowledge and set good examples on food safety and kitchen hygiene for the rest of the community.

Nike

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login