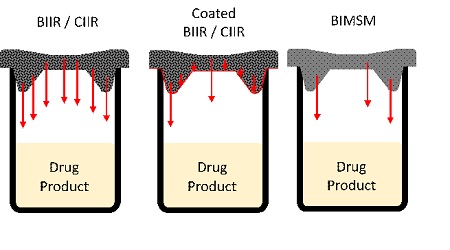

As drug packaging systems evolve to meet the complex needs of the pharmaceutical industry, BIMSM (brominated isobutylene co-paramethyl styrene) has become a material of choice for packaging closures, such as stoppers and plunger tips. BIMSM delivers a high level of cleanliness by significantly reducing the amount of extractables compared to halobutyls such as BIIR or CIIR, but without the added manufacturing complexity or other drawbacks of a coated stopper/plunger.

Pharmaceutical closures seal and protect the drug product from external contamination while, at the same time, allowing it to be accessed via needle puncture (stopper) or delivered through a syringe (plunger). In both of these key packaging applications, contact between the drug and the closure are expected to be nearly continuous over the lifetime of the product. This constant contact requires that the material chosen for the closure be clean and compatible with the drug product.

There are many materials available to meet various packaging needs. For packaging applications with long-term contact requirements, Isobutylene based elastomers have been the material of choice for many decades due to their low level of interaction with active ingredients; low permeability to oxygen and other gases; and relatively high level of cleanliness (low extractable content).

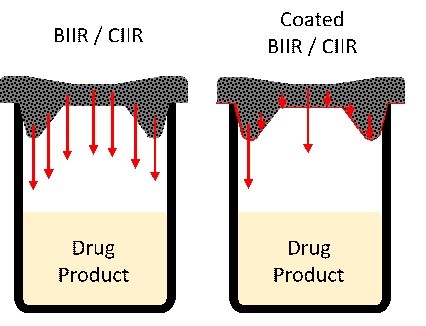

Bromobutyl (BIIR) and Chlorobutyl (CIIR) are the most widely used isobutylene based elastomers in pharmaceutical closures. To improve the cleanliness of these elastomers, a thin fluoropolymer coating can be applied to the stopper or plunger to inhibit the migration of low molecular weight contents from the elastomer into the drug product.

Figure 1: Schematic of uncoated stopper (left) and coated stopper (right) illustrating the effect of the coating

This enhancement to the cleanliness of the closure, however, comes at a cost: increased material costs; increased manufacturing complexity and part rejection rate; and interference of the coating with other performance parameters of the stopper (i.e. fragmentation / coring).

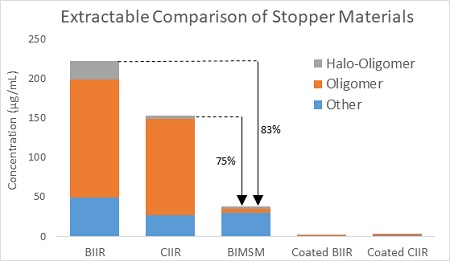

As a result, pharmaceutical packaging manufacturers are turning to another isobutylene elastomer option, BIMSM (brominated isobutylene co-paramethyl styrene). BIMSM can significantly reduce the amount of extractable content as compared to BIIR or CIIR without the added manufacturing complexity / cost of a coated stopper.

Figure 2: Isopropanol extraction for 24 hours at 72.6℃ followed by GC-MS separation and analysis.

Note that the BIMSM polymer used in this study is ExxproTM specialty elastomer produced by ExxonMobil

This extractable reduction comes from 3 main attributes of the BIMSM elastomer which eliminate the source of the extractable, rather than simply blocking it from extracting: 1) Fully saturated polymer backbone requiring no anti-oxidant; 2) Low oligomer creation during the polymerization process reduces extractable oligomers content at the source; and 3) Highly reactive benzylic bromine cross-linking chemistry allows sufficient cure with low levels of curative.

As materials used in pharmaceutical packaging continue to evolve, a clear understanding of the performance and value that each material can bring should be weighed carefully during material selection. For pharmaceutical stoppers, BIMSM can significantly improve cleanliness, as compared with standard halobutyl, while avoiding the manufacturing complexity and higher cost of coated stoppers.