GLOBAL Water & Energy, a member of the Global Water Engineering (GWE) Group of Companies, shares how the FLOTAMET™ anaerobic digestion plant is removing pollution from wastewater and transforms it into green energy to fuel boilers at a leading dairy production operation.

The FLOTAMET™-M system installed at HP Hood’s plant in Vernon, New York, is a key component of an integrated wastewater treatment line installed by Global Water & Energy, that is achieving 99% removal of organic waste material from high strength dairy production wastewater.

The Waste Water Treatment Plant installed at HP Vernon replaced an older treatment plant in order to achieve outstanding discharge qualities to local municipal treatment facilities, as well as to provide optimum treatment of high-strength waste from another HP Hood Plant at Oneida, NY.

Removal of this outstanding percentage of the wastewater’s Chemical Oxygen Demand (COD) load means wastewater effluent leaving the plant is of such high quality that it dramatically reduces the impact of the HP Hood facility on the Town’s small municipal treatment plant, which receives the treated effluent, significantly improving their operation.

“And the technology is a double winner because not only does HP Hood’s Vernon plant achieve some of the best COD removal levels achieved globally, but also the biogas produced (primarily methane) saves the plant money by replacing natural gas previously purchased to fuel the plant’s boilers. As in most food and beverage plants, that fuel is an important part of production processes and a major expense,” says Global Water & Energy Vice President, Mr. Ian Page, whose company is a subsidiary of GWE.

The available footprint for construction of the new wastewater treatment facilities was also very restrictive. However, the Global Water & Energy system was able to fit in the available space and integrate well with the existing facilities, unlike other technologies HP Hood had investigated.

GWE, headed by Chairman and CEO Mr. Jean-Pierre Ombregt, has successfully built and commissioned over 200 biogas utilization plants for clients worldwide over the past 15 years. Such plants produce green energy from pollution present in wastewater, using high-performance anaerobic bacteria to digest the dissolved and suspended organic matter, which is converted into biogas, a mixture of methane and carbon dioxide.

HP Hood’s Mt Vernon plant – with a capacity of 1,052.3 m3/d (278,000gpd) wastewater and 24,765 kg/d (54,600 lb/d) COD – is one of the latest and most efficient GWE plants, featuring FLOTAMET™ technology that is particularly suitable for wastewaters rich in fat, oil and grease (FOG) and Total Suspended Solids (TSS). Such technology is suitable for wide range of industries, including dairy production; meat, fish and food processing; biodiesel production and for any industry with a high strength waste stream.

“The FLOTAMET system, for which no pre-treatment is required, offers reliable operation and superior removal efficiencies, leading to increased biogas production and improved effluent quality,” says Mr. Page. In the HP Vernon application, it has demonstrated these qualities in service for more than a year, achieving:

• > 99% COD removal across the entire process (including anaerobic and aerobic polishing)

• > 96% COD removal in the FLOTAMET™ system. GWE’s ANAMIX™ reactor, the core process in the FLOTAMET system, achieves superior mixing of influent with anaerobic digestion biomass by means of a top entry agitator that ensures that the influent is in constant contact with the biomass that consumes and converts waste material to biogas.

• Reliable handling of wastewater elements that may trouble conventional waste water technologies, including elements such as spoiled products (slops), as well as significant fats, oils, grease (FOG)

Produced under the market signature “Always Good, Always Hood,” HP Hood LLC is one of the largest and most experienced aseptic production and extended-shelf-life (ESL) beverage processors in the United States. Using state-of-the-art, ultra-high-temperature (refrigerated and aseptic) manufacturing, with current and emerging packaging technologies, Hood provides a variety of branded, licensed, and private label products including fluid dairy, citrus, cultured foods, frozen desserts, extended-shelf-life dairy and non-dairy beverages.

Mr Page says the new waste water treatment plant provides an example to food and beverage manufacturers globally of how an outstanding corporate citizen can help protect the local environment and community water resources while also reducing the cost of their own operations and their dependence on fossil-based fuels.

FLOTAMET™- M SYSTEM

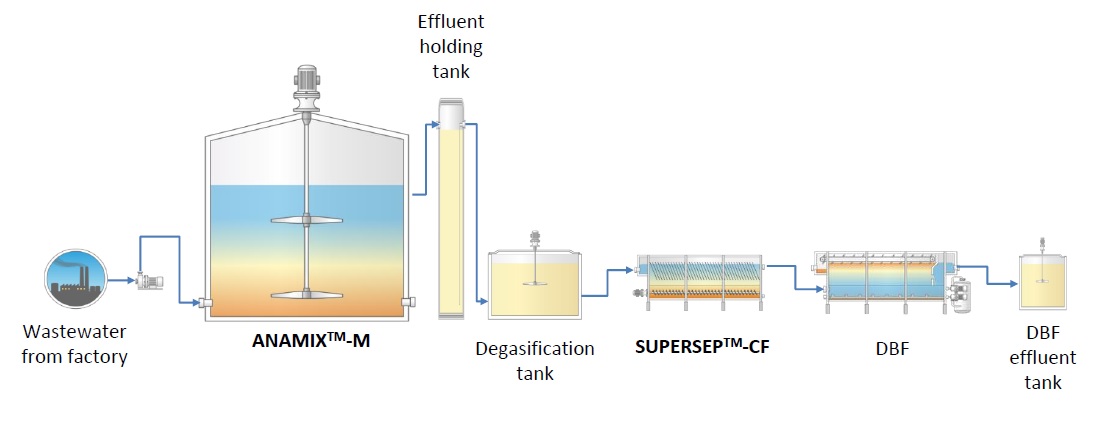

GWE’s FLOTAMET™-M system consists of a mixed methane reactor ANAMIXTM- M followed by a sludge separation stage consisting of a SUPERSEPTM – CSF and Dissolved Biogas Flotation (DBF) unit. The system, which is capable of handling medium loading rates, occupies a reduced physical footprint compared with alternative complete anaerobic treatment systems. In addition to the anaerobic digestion technology, the system incorporated aerobic polishing, the final wastewater treatment stage before discharge, as well as odor control and equalization of flow rates to prevent surging and maintain system performance and efficiency.

The FLOTAMET™ process consists of a mixed anaerobic reactor (GWE’s ANAMIX™) followed by a sludge flotation stage. It is suited for wastewaters with COD values up to about 100,000 mg/l and more, and wastewaters containing medium to large amounts of suspended solids, FOG, and/or salt.

Technical configuration - FLOTAMET™-M system installed at HP Hood’s Vernon NY plant, comprising:

ANAMIXTM-M

The methane reactor ANAMIX™-M is a completely mixed reactor (CSTR- Continuous Stirred-Tank Reactor) operated under mesophilic conditions, allowing high-performance anaerobic bacteria to digest the dissolved and suspended organic matter which is converted into biogas, a mixture of methane and carbon dioxide. The reactor is a cylindrical steel tank with a conical roof and flat bottom. Good mixing is achieved by means of a top entry agitator which ensures that the influent is in constant contact with the biomass.

SuperSep™ -CFS

GWE’s SuperSep™-CFS consists of a coated carbon steel tank with built-in lamella packages and with a double semi-conical bottom with sludge conveying auger (shaftless screw). Settleable sludge particles are separated in cross-flow mode, as the water flows horizontally through a series of inclined lamella’s. The settled sludge is collected at the bottom and is recycled back to the anaerobic reactor by means of 2 sludge pumps.

Dissolved Biogas Flotation (DBF)

DBF is the process by which suspended solids or any particulate matter are removed from the wastewater using the principle of bubble flotation. A DBF uses biogas which is compressed and dissolved into the water (clarified effluent in the DBF tank). The saturated water is then injected into the DBF tank, allowing contact with high suspended solids wastewater (effluent of the Membrane Reactor). The sudden drop of pressure inside the DBF tank releases the dissolved gas from the solution, producing the microscopic bubbles. These bubbles are attached to the suspended solids that float on the top surface after which they overflow in the sludge tank and are then returned to the reactor. Clarified effluent is discharged from the bottom of the tank.