AT ProPak Asia Gebo Cermex, alongside Sidel, exhibited its latest technologies: the CoboAccess™_Pal cobotic palletising solution; the AQFlex® intelligent, all-in-one product handling solution, and the WB46, featuring the 360° approach applied to wrap-around mechanization.

CoboAccess_Pal: much more than a cobot

Visitors to the Sidel Group stand at ProPak Asia (BW01) saw a first-hand experience of this robust palletiser, that leverages the advantages offered by cobotic solutions in terms of compactness, flexibility, production line efficiency, reliability and – especially – increased welfare for operators. Particularly suited for low-speed applications and underlining the company’s commitment to help producers embrace Industry 4.0 opportunities, the latest addition to the Access family of machines is designed to handle Regular Slotted Container (RSC) and wrap-around blanks. Moreover, CoboAccess_Pal embeds top safety and industrial standards to perfectly match the needs of very demanding production environments. As such, it has received a third-party certification[1]; all of that in addition to the equipment’s full compliance with European Machinery Directive 2006/42/EC. The Access portfolio on display will be complemented by RoboAccess®, a flexible robotic palletising solution as well as the layer-by-layer palletising platform PalAccess®.

In this video, Guido Ceresole, Zone VP South East Asia Pacific, Gebo Cermex talks about the CoboAccess_Pal:

AQFlex – Freeing product innovation thanks to total flexibility

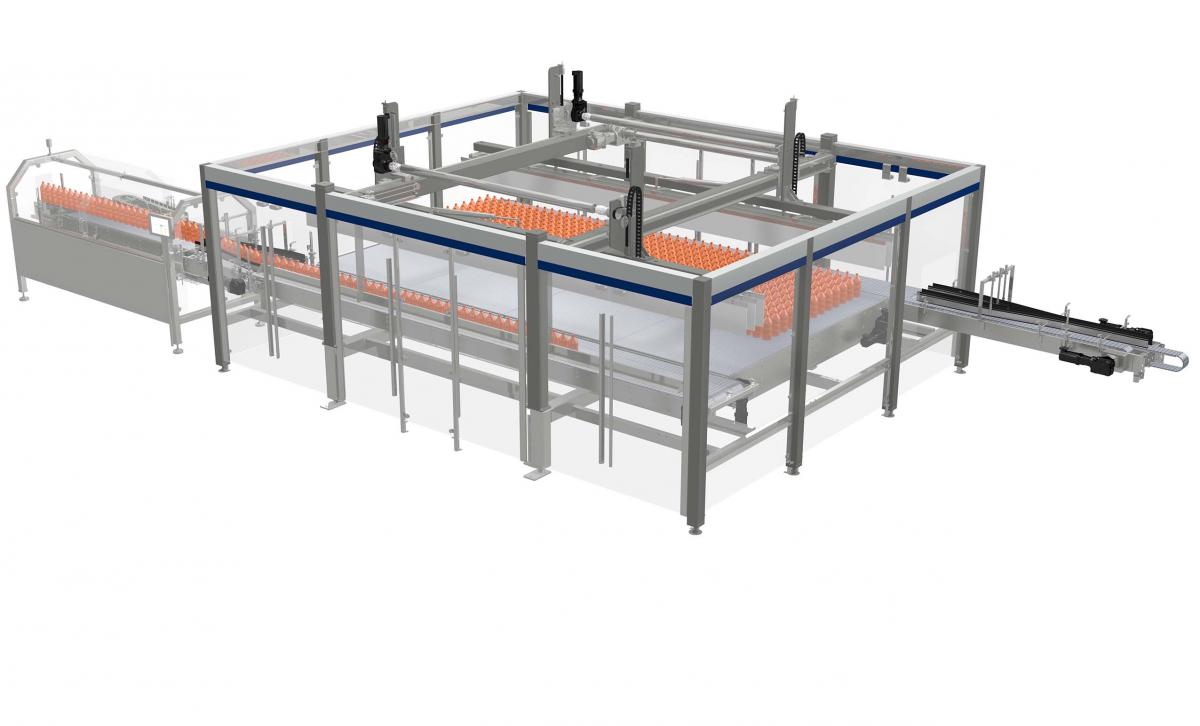

Liquid packaging producers are becoming increasingly demanding when it comes to their line requirements. They cannot afford to compromise on extended performance in terms of production uptime, efficiency and reliability, always paying close attention to minimising Total Cost of Ownership (TCO). AQFlex has been introduced by Gebo Cermex to answer these challenges, as it is an all-in-one product handling technology able to accommodate any product, whatever the application, whatever the market, in all container materials, formats and shapes, full or empty, while also enabling automatic changeovers and ensuring total care of product integrity. AQFlex delivers unprecedented packaging line performance, together with unique agility and smooth contactless product conveying and accumulation, in a very compact space. Up to 40% smaller compared to traditional solutions, the system offers the best accumulation/space ratio on the market. The solution, furthermore, has the ability to operate at any speed, from 1,000 to 100,000 containers per hour, delivering energy savings of up to 60%, without compromising high efficiency (99.5% even at high speeds).

AQFlex all-in-one product handling technology

The best-selling WB46 wrap-around case packer

The WB46 offers excellent performance in terms of flexibility, hygiene and ergonomics. This is due mainly to a new automation platform, thermoplastic polyurethane timing belts and quick-release systems for format changeovers. Additionally, thanks to its new on-the-fly robotic product loading station, the overall footprint of the machine is significantly reduced, as the need for a pre-collating system is no longer present. This latest version of the WB46 is featuring the company’s brand-new, user-friendly human machine interface (HMI), which is based on an intuitive, tablet-approach navigation and offers media tools for preventive maintenance procedures. The WB46 - presented via a dedicated station at the Group’s stand at ProPak Asia - is demonstrating that the 360° approach applied by Gebo Cermex to wrap-around mechanization is the right direction to go in. Gentle primary packaging handling, extended secondary packaging knowledge, and large mechanization expertise allow the company to play a leading role in this field.

The wraparound case packer installed at FrieslandCampina in Thailand.

The company has been serving customers in South East Asia for the past 10 years, and 15 years in Thailand where the food, beverage, home and personal care market is growing and productivity of operations and manufacturing standards are rising. Changing consumer habits show a focus on quality - especially in the alcoholic beverage segment more and more premium products are called for - as well as on natural ingredients and effective products with multifunctional benefits. Producers need to secure best performance in several areas across their supply chains like flexibility, reliability, low total costs as well as product and brand quality.

[1] Gebo Cermex CoboAccess_Pal is certified by Apave.

Off White X Max 180-90

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login