Temperatures vary for hair devices and appliances. Blow dryers used at home force air at temperatures between 55° to 75°C; home-use curling irons work at temperatures between 80° to 180°C, depending on the model; and straightening irons have operational temperatures that range from 140°C to 300°C, with salon models often working at the higher end of the range.

The temperature of blow-drying is around 55-75°C and it is usually used especially in the home after washing hair. The temperature of home- rolling iron is within 80-180 ˚C, depending on different type of rolling iron. Plat iron by home-made or salon-use has the highest temperature from ˚C. Other process in salon such as curling, straightening, dying is within wide range temperature within 80-300°C.

Based on above processes and temperature levels, we can associate the types of heat damage with three temperature ranges: first, at 55-80°C, then 80-140°C, and finally, at 140-300°C. What sort of effects can be expected with constant exposure to such heat levels?

At the first level, cuticle will open as the hot air is blown on the wet hair when wet, 2-3% moisture will start to vaporize from the inner layer of the hair (cortex) will start to vaporize. With constant rubbing action, say from a brush, cuticles become more brittle and more easily damaged. Especially with rubbing action, brittle cuticles are easily damaged or broken off.

At the second level, hair volume will expand and cuticles become brittle, damage, then break off within which protein and melamine are lost.

At the third level, hair becomes more and more damaged, which is made apparent by less gloss (irregular cuticle), dryness, frizziness (exposed cortex), and reddish color (melanin loss).

Since many consumers frequently style hair with these devices, products intended to protect hair from the effects of heat is becoming one of their hottest requirements from the consumers. There are several materials that can be used to formulate such hair products; however, the level of protection that they may offer can vary. One way to determine the efficacy is to perform tests on hair samples that have been treated.

Four different ways to measure heat protection properties of a material are discussed in in this article:

Observation of hair – Use a scanning electron microscope (SEM) to observe cuticle damage directly; the less damage, the better heat protection.

Hydrophobicity of hair – The more hydrophobic, the better integration of the cuticle and the better protection given.

Tensile strength of hair – This test checks hair cortex flexibility, which can decrease with heat damage cortex. The more power required to break hair, the stronger the hair cortex as a result of better protection given.

Thermal gravimetric analysis (TGA) – This quantitative method measures the quantity of volatile components and determines thermal decomposition by weight loss. The more stable the material with increasing temperature, then the better the protection than can be given.

For this exercise, the heating protection properties of several materials were tested and compared. These included several polymer materials, such as VP/VA copolymer, polyurethane and acrylates copolymer.

Methodology

The hair samples were prepared prior to each test in the following manner:

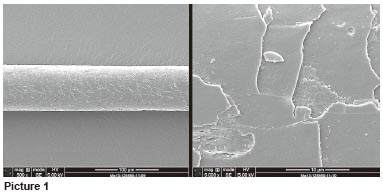

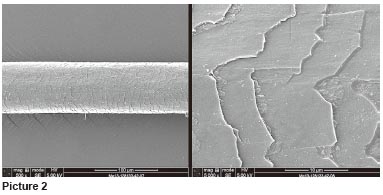

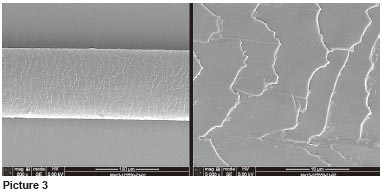

Scanning electron microscope Prior to observing the appearance of hair shaft with the SEM, hair samples were washed with shampoo, rinsed and blow dried. One sample was the control to which no product with polymer material was applied. Products with polymer material were applied to the remaining. Cuticle appearance was observed using SEM and compared with the control hair sample.

Hydrophobicity Spray material solutions (2%) on hair and dry overnight. Apply iron heated to 190°C for 10 seconds to hair for 8 times. Wash off material solution. Apply a water droplet from fixed burette to the hair samples, including a control hair sample. To the hair cuticle's hydrophobicity, measure the droplet diameter for each sample and compare to the control.

Tensile strength Pre-treat hair (Asian, 18cm by 4.5cm, 4g, divided into three equal strands) using guide formulation with and without polymer (2% active). Dry the hair overnight, straighten the hair with hot iron at 190°C, applying for 10 seconds for 8 times from root to tail. Draw hair at rate until hair is broken by ZWICK tensile machine; record the tensile strength when the strength is recorded as broken tensile strength.

Thermal gravimetric analysis (TGA) The pure materials are heated from room temperature to 600°C (heating rate is 20K/min).

Results and discussion

Cuticle observation under SEM Unprotected hair, or the control (Picture 1), showed the most significant signs of damage, including cuticle split, spallation, degradation of the edges, and breakages along the hair. Hair treated with VP/VA copolymer (Picture 2) is an improvement over the control but still shows signs spallation of cuticle edge and breakages along the hair. Hair treated with polyurethane-48 (Picture 3) shows an even healthier hair and cuticle appearance, indicating that the polymer provides better protection against the effects of heating.

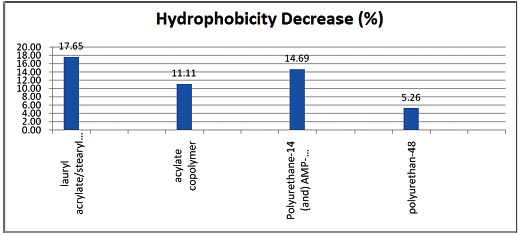

Hydrophobicity is a characteristic of a healthy cuticle, and this test measure the effect of heat on the surface of the cuticle. The less smooth and integrated the cuticle is, then the greater the decrease in hydrophobicity. Conversely, the lower the decrease in hydrophobicity, then the healthier the hair. In Chart 1, hair treated with the lauryl acrylate/stearylacrylate/ethylamine oxide methacylate copolymer shows the greatest decrease in hydrophobicity at 17.65%, and hair treated with polyurethane-48 is measured to have the lowest decrease in hydrophobicity at 5.26%, once again indicating its protective ability in heated hair.

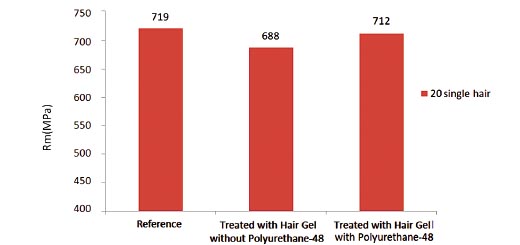

Tensile strength Chart 2 shows that without heating, the reference hair sample (control) needs 719 MPa to be broken. Hair that was heated then treated with a hair gel with polymer polyurethane-48 required more pressure at 712 MPa than the sample treated with a hair gel without polymer polyurethane-48 to be broken.

TGA results indicated that below 350˚C, polyurethane-48 offered the best stability through weight loss followed by polyurethane-34, polyquaternium-11 (70h drying box), acrylate copolymer, and acrylate copolymer (70h drying box), which is consistent with the hydrophobicity test results.

In conclusion four different tests, SEM, hydrophobicity, tensile strength and TGA, were used to measure and compare different the heat protection ability of polymer materials on hair that has been exposed to heat treatment via hair devices. According to these measurements, the polymer polyurethane-48 provides the best heat protection not only to the hair cuticle but also the hair cortex. Polyurethane-48 can be an effective ingredient that could be widely used in hair styling and conditioner products that claim “heat protection".

CHART 1

CHART 2

Air Max 95 Flyknit