GUMMIES and jellies have come a long way from the classic gummy shaped like a bear and the jelly that looks like a cup. New shapes and colours continue to delight children everywhere, thanks to more innovative confectionery equipment. It is even possible to add a soft or hard filling in these sweets.

3D or full-form jellies and gummies are the attraction today. Considered a high value product, they can come in ball, fruit, animal and even cartoon character forms. But these lifelike shapes can be made only through starchless depositing into solid moulds. In contrast starch moulding systems can only produce gummies with 2D surfaces and a flat base.

Complex, full-form shapes like strawberry created using the ServoForm 3-D depositor

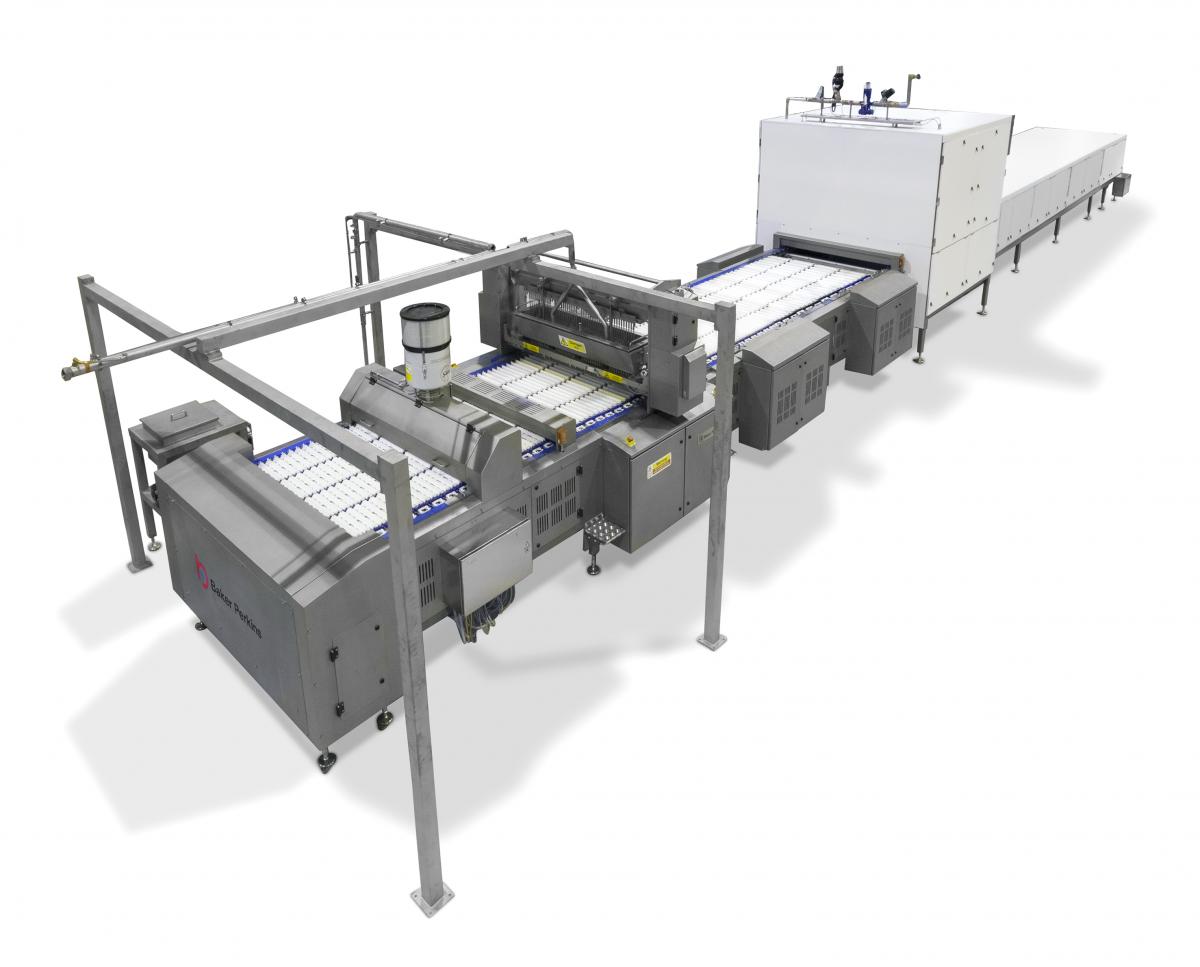

The 3D depositor from Baker Perkins, known as ServoForm 3-D depositor, is the first fully automated system for making high value gummies. It is capable of outputs ranging from 100 to 1,000 kg/hour. The machine is touted for its 100% ejection rate, as well as its ability to reduce cost.

To ensure fast changeover between production runs, the mould system uses a carrier design with clip-in moulds that allows rapid low-cost product changes. This widens the range of products that a single line can produce, and this versatility may be enhanced by the ability to deposit multiple shapes in different colours simultaneously. A single ServoForm depositing line can produce the same product range as a number of smaller low output lines – but at much lower cost.

Baker Perkins’ new capability is making inroads into the growing jelly and gummy sectors by adding chewy textures to the range of products that can be made on a starchless line. Traditionally, these have been made in starch moulds while softer textures using pectin, carrageen, starch, or a combination, have long been manufactured successfully on starchless lines.

Starchless depositing of jellies and gummies offers substantially reduced capital and operating costs compared with starch moguls, with significantly improved hygiene. Lower operating costs are based on eliminating consumables and reducing energy consumption as well as requiring less labour, cleaning and maintenance. This makes gummy production economically viable for companies of any size, from start-up operations to established high-output manufacturers.

From Baker Perkins, the ServoForm 3-D depositor is the first fully automated system for making high-value gummies

Not just for the sweet tooth

The accuracy and hygiene of starchless moulding make it the ideal process for the functional and medicated confectionery sector. Products are of consistently high quality to support high pricing and healthcare positioning.

Jellies and gummies can be fortified with a variety of ingredients with a healthy characteristic including fruit juice, real fruit pieces, fibre, protein and energy supplements. In healthcare, jellies and gummies are used to carry vitamin and mineral supplements.

Some medicated products are more suitable for delivery using hard candy, particularly where slow release of the active ingredient is required. These include antiseptics, menthol and eucalyptus oil to alleviate the symptoms of minor ailments such as coughs, colds, sore throats and nasal congestion.

The high product quality and hygienic nature of the process are making starchless depositing the process of choice. Crucially, the process adheres to the principles of GMP and is readily capable of validation to FDA/EMEA standards. Baker Perkins has specialised in starchless depositing for many years and has installed over 500 lines installed worldwide. As well as providing equipment, training and service the company offers full product and process development services in its Innovation Centre.

The starchless process does not degrade expensive active ingredients, and there is high accuracy throughout mixing, cooking and depositing. Exactly the right proportion of active ingredients is added, every deposited piece is precisely the same weight, and the process is reproducible.

Gelatin gummies

Baker Perkins has collaborated with Rousselot, a leading gelatin producer, on a new process and ingredient technology for the production of gelatin gummies on starchless depositing systems.

Rousselot’s SiMoGel solution allows gummies produced on Baker Perkins ServoForm depositors to dry in minutes, rather than the 24 hours typical with a conventional starch moulding mogul.

Baker Perkins starchless jelly and gummy depositing systems offer a unique capability to produce full-form 3-Dimensional jellies and gummies.

Nike Roshe