RAPID urbanisation, rising incomes, and greater awareness of food safety and available health options are major trends contributing to Asia’s fast-growing demand for milk and dairy products. According to leading Dutch dairy cooperative, FrieslandCampina, consumption has doubled in the region in the last 30 years, with China, India and countries across Southeast Asia dominating the global dairy industry.

The abundance of new products and packaging alternatives, coupled with increasingly stricter regulations, are resulting in an ever-complex dairy supply chain. Evolving consumer trends such as the demand for healthy and ‘clean label’ products, increased demand for functional foods, growth in protein consumption, and preference for dairy alternatives (e.g. lactose-free and plant-based options) continue to push innovation in the sector. Businesses therefore need to look beyond developing robust technological capabilities to take advantage of these major trends.

Dairy processors can no longer afford to ignore the risk of scandal and product recalls. They also face constant challenges, such as ensuring dairy products remain fresh from start to end, and keeping a close watch on their bottom line.

“The good news is that most are already enforcing strong measures to ensure their supply chains are secure and their products are safe and contamination-free as today’s consumers demand greater transparency,” says Nalin Amunugama, General Manager of BOGE Asia Pacific, specialists in compressed air solutions.

New technologies to track products along the supply chain are emerging on the market. From connected devices that analyse data, to platforms like blockchain, dairy supply chains are constantly looking to innovations to improve efficiency, productivity and safety.

Blockchain disruption

From farm to store, errors in the food supply chain can be difficult to detect at every step. This becomes even more of a problem on a global scale when companies try and cut corners, just to save on costs. It is thus vital for suppliers to make transparency a priority and invest in track-and-trace technology that can seamlessly validate their ingredients from origin to purchase.

In the dairy context, these issues highlight the 2008 melamine scandal in China, when 54,000 infants were hospitalised and six died due to the contamination of infant formula with melamine. The incident reinforces how vital it is for companies to understand what is happening at every stage of their supply chain, as a lapse anywhere can ruin a company’s reputation. Collaboration among the various players is now more important than ever.

As a shared, secure record of exchange, blockchain technology could be used to track what goes into a product and who handles it along the way. Each ingredient or product component is assigned a unique identification number that allows it to be traced, even as ingredients from different sources are added and the product is developed. And because the blockchain database can be accessed by anyone and verifications can be carried out as needed, the process stays transparent.

A ‘Foodchain’ prototype developed by Deloitte Ireland has shown to successfully track all the ingredients in a specific product across the entire supply chain. Through a simple process of scanning the product’s RFID tag via a mobile app, the technology allows consumers to identify the origin of each ingredient.

IoT is expediting the export of fresh milk from Australia to China and Southeast Asia, by improving inspection processes

Crossing borders

With the help of the Internet of Things (IoT), Australian milk producers can now export fresh milk to China in record time. Through Peloris, a company specialising in cross-border supply chain, milk products reach the Chinese market in less than two days – a vast improvement from a couple of years ago, when shipment of milk products to China typically took two to three weeks just to pass through quarantine! Peloris, working in partnership with Australian telco Telstra and M2M Connectivity, successfully utilises IoT to preserve the integrity and traceability of fresh milk.

As milk needs to be kept at 0 to 4 degrees Celsius, monitoring temperature becomes crucial. When the product arrives at the border, it can quickly be processed, since transportation and handling information is easily accessed during inspection. The end customer can also gain insight into some of the recorded data by scanning the barcode on the product.

To measure temperature and location in real time, Telstra and Peloris use a data logger device that uploads information to the cloud every 15 minutes. The device also measures light emissions, tilt monitoring, humidity, and air pressure from point to point. To date, Peloris has successfully delivered its two millionth litres to China.

Managing Director, Peter Verry remarks, “This visibility and transparency allows us to see the products at all stages of the supply chain, helping to improve overall efficiency. Where it used to take weeks to clear shipments, we can now achieve this in just 36 hours.”

As part of its expansion plans, Peloris is setting up supply chain channels to distribute other short shelf-life products like meat, fruit, vegetables and chilled seafood from Australia to China and countries like Singapore, Thailand, Vietnam Indonesia through its newly established office in Malaysia.

Non-thermal processing technologies are increasingly being applied to dairy products like yogurt to preserve freshness

Cool and fresh

Making big waves in food processing in the dairy industry are non-thermal processing technologies like power ultrasonic systems and pulsed electric fields. Unlike traditional pasteurisation, these techniques kill food-borne pathogens without the use of high temperature that would otherwise compromise the product’s quality and nutritional content. Clean-label food manufacturers are also drawn to their ability to remove some preservatives from food products.

One cold pasteurisation technique that is already in operation in Singapore is high pressure processing (HPP). The advanced food processing technology employs ultra-high pressure to inactivate bacteria, while preserving essential nutrients that are normally destroyed when subjected to extreme temperatures. Since no preservatives and heat are applied, food taste, texture and nutritional value are minimally affected, and the products stay fresh longer.

The introduction of the first HPP line in Singapore in 2016 has since helped companies like The Soup Spoon to develop preservative- and additive-free soup packs, with an extended shelf-life, from three weeks to three months. As a result, the company is now able to export its products beyond Singapore, to countries in the region.

HPP is now commonly used in applications for dairy-based products like yogurt, cheese and ice cream. In yogurt production, for example, HPP helps to improve curd firmness and reduce build-up of whey on the surface.

Dutch company, CoolWave Processing is also making significant impact with its PurePulse preservation technology. Through a series of short electric pulses, it renders bacteria in raw milk inactive, while retaining the product’s taste, quality and nutritional components. The technology is capable of achieving a product shelf-life comparable to that of heat-pasteurised products.

Pure and clean

Often regarded as the fourth important utility after water, electricity and gas, compressed air plays a critical role in food manufacturing. In dairy production, compressed air is used to aerate the milk in the silos, and in filling, sealing and packing processes. As milk is especially sensitive to pathogenic and non-pathogenic microorganisms, contact with contaminated air can lead to spoilage, affecting product taste, smell and quality.

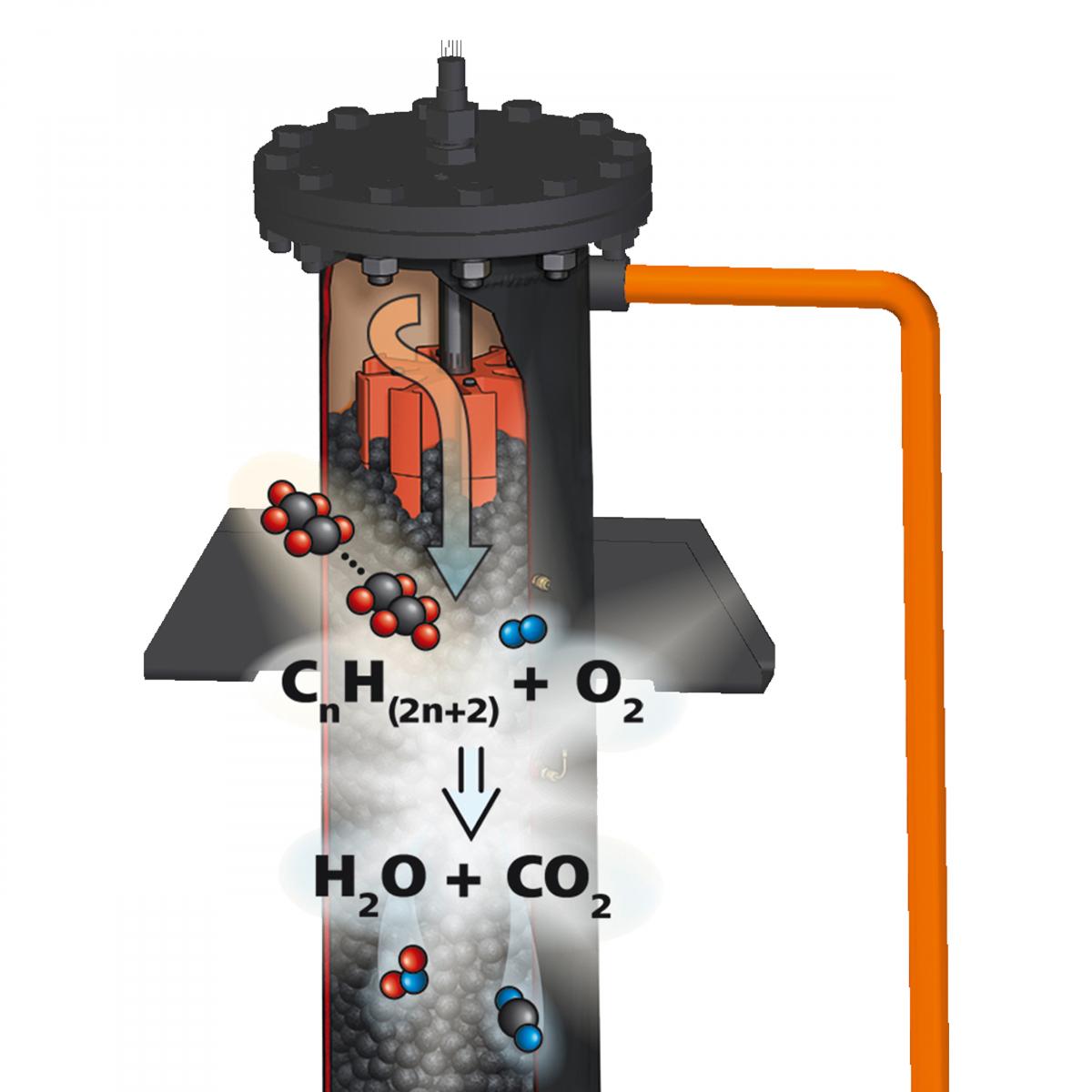

Innovative solutions like BOGE’s BLUEKAT compressor provide a steady supply of clean compressed air for dairy manufacturing. Its integrated converter, also known as a catalytic converter, oxidises oil to carbon dioxide and water in a chemical reaction, and in the process prevents oil from breaking through. It simultaneously ensures that the compressed air meets the most stringent of standards for purity class 0 oil-free air. Besides the removal of active hydrocarbons during the conversion process, microorganisms and bacteria in dairy production are also reduced due to the processing temperature of 230 degrees Celsius.

“Compared to non-integrated or external downstream converters, BOGE’s integrated solution offers better heat management, which is significantly more efficient and cost-effective,” says Mr Amunugama.

The BOGE converter principle is based on the most stringent standard for achieving purity class 0 oil

Changing market dynamics

Digitisation and transparency have led to evolving trends in the dairy supply chain industry. It is essential for businesses to rethink supply management strategies, especially when customers have access to unlimited information and choices. They will have to implement programmes that incorporate tougher controls and stricter surveillance if they are to introduce quality products that effectively address the changing market dynamics.

For companies aiming to get ahead of the game, they must strive to do something bold, different and innovative.

Nike