Several information and communication companies are finding recent component solutions advantageous in changing the overall appearance and functions of the products they turn out.

Founded in 1976, Acer is one of the world’s top ICT companies and has a presence in over 160 countries today. From service-oriented technologies to the Internet of Things, gaming and virtual reality, Acer’s 7,000+ employees are dedicated to the research, design, marketing, sale, and support of products and solutions that break barriers between people and technology.

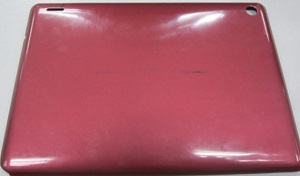

Over the past few years, there has been a trend towards lighter and thinner tablets. Fiber reinforcement materials (PC+GF) and proper product design are the key factors to reducing weight while maintaining the desired product strength and stiffness. In-mold Roller (IMR) process is often used to decorate tablet products; however, possible defects such as ink wash-out and stress marks tend to occur in the IMR process. Acer used Moldex3D DOE (Design of Experiment) analysis to examine possible defects and achieve optimum gate design and process conditions.

By utilizing Moldex3D DOE to achieve optimum gate design and process conditions, Acer has been able to identify the best gate type to reduce shear stress and avoid ink wash-out, reduce the wall thickness significantly by 48%, and reduce product weight by as much as 40%.

The Moldex3D DOE has been able to solve the challenge of ink wash-out and stress marks in an ultra slim tablet. Through Moldex3D analysis, Acer identified high shear stress in the design.

Acer set 11 sensor nodes on the gate and ran Moldex3D Flow analysis to check the shear rate of the sensors and compared it with the experimental results and they showed that the problematic areas have higher shear rate. Therefore, shear rate analysis results might serve as an indicator and can help minimize ink wash out.

In order to reduce the shear stress developed across the gate and the mold cavity, Acer designed 7 sets of gates with different dimensions and locations and ran Moldex3D Flow analysis. After comparing the shear rate results, four designs were chosen as the optimal process designs.

Secondly, Acer performed Moldex3D DOE analysis to analyze the different types of meshes and gates in the 4 chosen designs, then set two quality factors: the shear rate and sprue pressure during the filling as smaller-the-better. Based on the Taguchi method, four control factors and four levels were selected for analyzing Signal/Noise (S/N) ratio

According to the simulation results, the S/N ratios indicate that the mold temperature and the flow rate are the main control factors of the ink wash-out problem. Moldex3D expert also helped identify the best run, which consists of the optimum processing parameters. By comparing the best and the worst run, Acer found that in the worst run, the shear rate curve of the gate area is very steep while the curve of the best run is relatively smooth. Based on the analysis results, Acer changed the gate design and then reworked the design, successfully solving the ink wash-out problem.

The ink wash-out problem has been successfully reduced.

Moldex3D’s virtual molding technology helped Acer obtain optimal mold designs in the shortest time possible. The thickness of the base case of the tablet has been reduced from 1.3~1.55mm to 0.8~0.95mm. The product weight has been reduced by 24%~40%, and the product thickness has been reduced 26.9%~48.4%. With the help of Moldex3D solutions, Acer is able to cut costly mistakes and gain a competitive advantage.

LED fillet-enhanced package

Samsung Electronics Co., Ltd., a world leader in advanced digital component solutions released two new additions to its chip-scale package (CSP) line-up: LM101B, a 1W-class mid-power LED, and LH231B, a 5W-class high-power LED.

Built with enhanced CSP technology, the new LED packages deliver industry-leading efficacy and reliability for spotlights and high-bay lighting applications. The FEC line-up represents an outstanding set of highly advanced LED component solutions that accommodates a variety of luminaire designs from below 1,000lm to well over 10,000lm.

The LM101B and the LH231B packages are based on Samsung’s state-of-the-art, fillet-enhanced CSP (FEC) technology, which forms TiO2 walls around the chip surface to reflect its light output toward the top, acting as a plastic mold in conventional EMC-based LEDs.

With its FEC design, the packages provide a higher light efficacy level compared to Samsung’s previous generation of CSP LEDs*. The more focused beam also helps to eliminate cross-talk between neighboring packages and enables the new packages to be placed in close proximity to one another, offering greater flexibility to luminaire designers.

“Our FEC line-up represents an outstanding set of highly advanced LED component solutions that accommodates a variety of luminaire designs from below 1,000lm to well over 10,000lm,” said Mr. Jacob Tarn, executive vice president of LED Business Team at Samsung Electronics. “Samsung will continue to pave the way for widespread adoption of CSP technology in the mainstream lighting market, bringing greater performance and cost benefits to a growing number of lighting manufacturers.”

The LM101B features the highest efficacy among currently available mid-power CSP LEDs with 200lm/W (Ra80 5000K, 65mA, 25˚C). Furthermore, with low thermal resistance (2K/W) and high reliability (0.5W, 105˚C, L90>50000 hours), the LM101B has been optimized for spotlights and high-bay applications where high efficacy and long lifespan are required.

With an operating current of 2A (max. 6W), the LH231B offers an efficacy of 170lm/W (Ra70 5000K, 700mA, 85˚C). This is the same high efficacy level offered by ceramic-based high-power LEDs, one that can bring a high degree of cost-effectiveness when applied to high-bay applications that require an output between 5,000 and 10,000lm. Thanks to Samsung’s FEC structure, the 120-degree beam angle allows for simple optic designs, making it also suitable for outdoor applications, such as street and parking lot lighting.

The LM101B and LH231B complement the currently available 3W-class high-power LH181B CSP LED, and the entire FEC lineup is now in mass production.

Low-power glass-free displays

E Ink Holdings, a company engaged in electronic ink technology, renewed its Master Supply Agreement (MSA) with Plastic Logic, designer and manufacturer of flexible, glass-free electrophoretic displays (EPDs). E Ink and Plastic Logic have been cooperating to develop the EPD market for more than 10 years. Plastic Logic owns the leading OTFT technology that is suitable for developing flexible EPD device in wearable applications.

According to IHS, the flexible display market will grow to $15.5 billion in 2022 as the popularity of wearable and mobile devices with flexible displays increase. Plastic displays lend themselves particularly well to wearables being light-weight, robust and requiring minimal power to function. They are a great choice for jewelry, watches and health monitors, to name a few applications.

“One of E Ink’s key market strategies is to partner with the industry leaders to expand the use of epaper in products and applications,” said Mr. Johnson Lee, President of E Ink Holdings. “E Ink is known for its leading-edge technology in EPD development and manufacturing. We expect the partnership to leverage E Ink and Plastic Logic’s expertise to provide more flexible applications to customers.”

Plastic Logic is a designer and manufacturer of flexible, glass-free electrophoretic displays (EPDs).

“We are excited by this next phase of partnership with E Ink. Signing the MSA creates mutually beneficial opportunities for geographic expansion, the penetration of new markets and the further acceleration of e-paper displays’ adoption in a multitude of applications.” Mr. Tim Burne, CEO, Plastic Logic commented, “Our leading-edge plastic electronic technology, proven manufacturing process and can-do customer focus enables our customers to bring robust, flexible, functional, low-power glass-free display-based products to market which create exciting opportunities for market growth, differentiation and competitive advantage.” IRNA