By Kathryn Gerardino-Elagio

During the Siemens PLM Analyst Conference, Zvi Feuer, SVP for Manufacturing Engineering Software, indicated that the top 5% of global companies are dominating the economy by exploiting digital competencies.

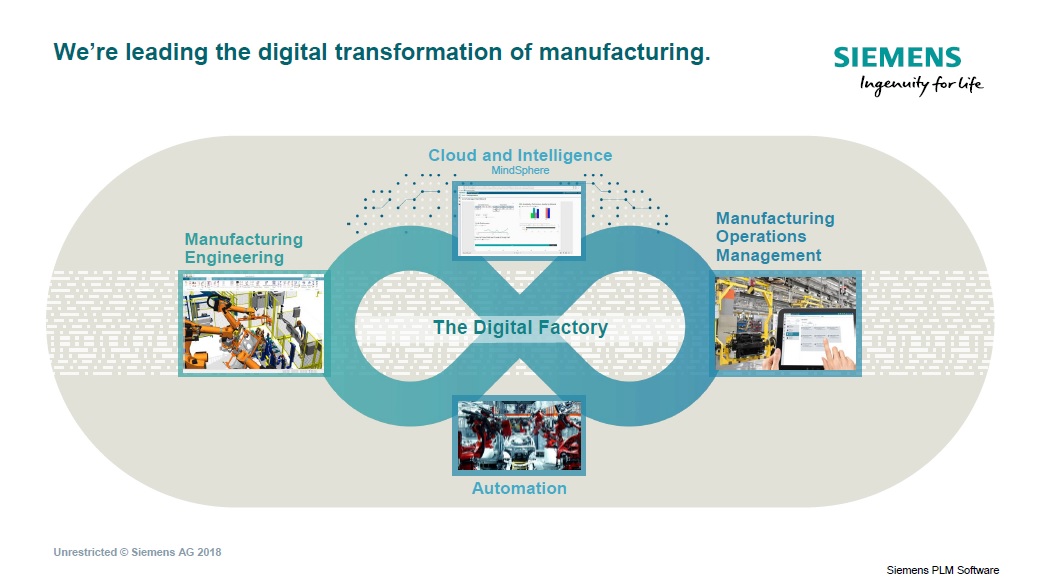

Siemens wants to bring digitalisation to manufacturing and democratise innovation to bring the digital factory to all companies. To realise the full value of digitalisation, the company has developed a collaborative platform to implement the digital twin across the design/build/operate/maintain/optimise lifecycle.

This platform merges the virtual product design and virtual production process with the real production systems and automation to produce the real product and to deliver it. It would include integrated product design and simulation to validate and verify the product prior to production. Virtual production simulation commissions and validates the physical production systems and automation.

This extends the use of the digital twin of the virtual and physical domains from product design via production to performance of the systems in a continuous process improvement environment.

Siemens Digital Factory involves multiple advanced technologies, such as physics-based modelling and simulation, AI and machine learning, virtual and augmented reality (VR/AR), IIoT and intelligent edge sensors, additive manufacturing, and advanced robotics.

Rethink manufacturing

As what Peter Diamandis, founder and chairman of the X Prize FoundationCofounder and executive chairman of Singularity University, said, “We are on the verge of transforming one of society’s most fundamental build blocks: manufacturing.”

And with this quote from Peter Diamandis, Zvi Feuer concluded that it’s time to rethink manufacturing. He said today’s production systems are reaching their limits of performance. Zvi deemed a digitally orchestrated flexible production is the solution.

“This digital factor vision requires planning and optimising dynamic production networks. One must simulate highly flexible networked production systems to plan equipment requirements based on predicted performance,” he remarked.

Zvi mentioned inventing new application fields with robots on demand by integrating the digital twin and physical automation to mobilise robots equipped for performing precision jobs at any scale. Next is transforming assembly quality and throughput by integrating advanced robotics, sensors, programming and production system simulation to automate complex smart product assembly. Also, accelerating introduction of next gen production concepts.

Zvi expounded, “By integrating mechanical and electrical design to generate PLC code automatically -and integrate automation hardware for the design and virtual commissioning of production systems.”

On another thought, Rene Wolf, SVP of Manufacturing Operations Management Software, who was also present during the conference suggested that to digitalise manufacturing is to unify virtual and real production, such as: (1) Cloud and Intelligence (MindSpehere) (2) Manufacturing Engineering (3) Manufacturing Operations Management and (4) Automation.

Rene Wolf urged operators to break through the screen barrier in production planning by bringing virtual simulation closer to reality with immersive and interactive VR experiences for work training. He said introducing AR in manufacturing operations will improve worker guidance and quality inspection. Operators must overlay virtual and real data for augmented EWI and real-time 3D views of as-design and as-build products.

Rene said integrating PLM and MOM transforms virtual production into highly efficient operations. “Take control of production schedules, execution and quality by orchestrating the complete operation,” he added.

Wolf explained that closing the loop with contextualised data from the shop floor prevent downtime, optimise processes, and improve designs with actionable insights gained from production data. Gaining global visibility into production data and insights via manufacturing intelligence technologies on MindSphere, impacts production KPIs with actionable insights gained from analyses of real time global operation data.

Siemens’ Mindsphere, a cloud-based, open, IoT operating system is the platform and backbone that will connect all aspects of the Digital Factory together. However, Mindsphere, as a platform, will support far more than just the Digital Factory. Mindsphere is the IoT and connectivity platform for a range of industries that include Smart Cities and infrastructure, power generation for fossil and alternative energy, process industries, healthcare, mobility, building technologies, energy management, and more. Siemens is building an expansive and global Mindsphere ecosystem of consulting, application developers, connectivity, and technology partners.

Siemens digital factory

The digital factory division aims to provide its customers with a comprehensive portfolio of hardware and software products which enable the comprehensive integration of data from development, production and suppliers. The complete digital representation of the entire physical value chain is our ultimate goal. We call the solution platform which we created for this purpose "Digital Enterprise".

Under this term the DF product portfolio already smoothly connects major parts of the product and production life cycle today. Powerful Product Lifecycle Management (PLM) software, for example, allows us to develop and optimise new products on an entirely virtual basis. In the real manufacturing world the Totally Integrated Automation (TIA) concept, which has proven its worth for about 20 years now, ensures the efficient interoperability of all automation components. The TIA Portal, for example, already enables significant time and cost savings in engineering.

In close cooperation with its partners within Siemens, and especially the Process Industries and Drives (PD) Division, the Digital Factory Division provides a large and unique portfolio of PLM software tools and industrial automation and drive technology tailored to meet individual customer requirements in various discrete industrial areas.

In addition, DF customers can rely on the division's commitment to the long-term development of their businesses. Protecting our customers' investments now and in the future – a particularly important consideration in the software business – is one of the major pillars of our business strategy. And when it comes to shaping the future of industry, DF is a driving and trendsetting force which joins with its partners worldwide in proven leading-edge technologies to increase productivity and protect a competitive edge.

Nike LunarEpic Low Flyknit

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login