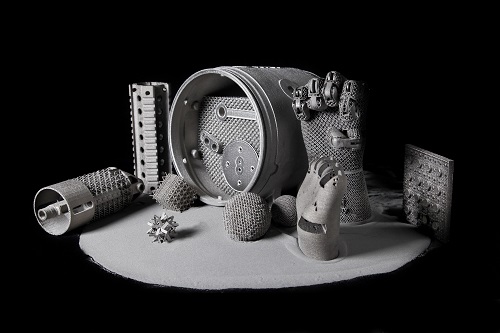

Metal additive manufacturing offers shorter build times and unrivalled flexibility in design.

The metals industry has long formed the backbone of the industrialised value chain, providing core materials for the aerospace and automotive sectors, in the construction of essential amenities and in consumer goods production. As populations urbanise, global demand will increase in tandem to meet infrastructural needs and manufacturing growth. By 2050, steel use is projected to increase 1.5 times that of current levels, while global lithium demand could double or even triple by 2030 – the latter driven in part by the expected growth of electric vehicles and energy storage systems.

Despite the industry’s importance, metal manufacturers have been slow to adopt new technologies that are powering innovation in fast-moving sectors. More than introducing quality products to the market (such as stronger and thinner metals for modern car and engine designs, and high-tech alloys in next-generation phones), these technologies are instrumental to addressing perennial issues like rises in material costs and operational inefficiencies. Climate change mandates and the move towards sustainability will also necessitate tech-driven innovation that focuses on scale reduction and low-energy production processes.

“Disruptive technology – from automation and robotics to analytics and remote monitoring – brings increased transparency, productivity and reliability across the supply chain. Such innovations improve efficiencies while reducing waste, helping manufacturers to minimise their environmental footprint,” says Nalin Amunugama, General Manager of BOGE Asia Pacific, a leading specialist in compressed air solutions.

The Future of Manufacturing

While additive manufacturing technology continues to make waves in a whole range of applications, the metals industry has been less quick on the uptake. As it is, metal additive manufacturing contributes to lower logistics costs as materials are supplied in powder form and end products are distributed locally or within the unit itself. In industrial manufacturing, laser melting and electron beam melting are among preferred metal-based 3D printing technologies as they significantly shorten build times and are particularly useful in producing medium-sized parts or single units.

A fundamentally new metal 3D printing technology, Intelligent Layering goes one step further by promising the reduction of final part cost by as much as 80 percent through low machine and material costs, and creative software design. Developed by US-based 3DEO, the technology produces metal components with quality surface finish using a layer-by-layer micro-end-mill cutting and a bulk sintering approach. A low-cost sprayhead increases the repeatability of the process, more so than if a laser or inkjet printhead were used. 3DEO currently manufactures with stainless steel powders, but is developing other materials like nickel alloy, titanium and copper.

3DEO’s President, Matt Sand, shares: “Metal 3D printing is essential to accelerate manufacturing but cost and complexity has kept it out of reach for most companies. With Intelligent Layering, we are uniquely positioned to help customers boost their productivity without a costly capital investment.”

The metal additive manufacturing market is predicted to reach over US$6.6 billion over the next decade. General Electric’s recent acquisition of two leading companies in metal-based 3D printing technology (Concept Laser and Arcam) is just one indication of the anticipated positive growth in metal manufacturing.

Optimisation with Quality Compressed Air

A crucial utility in metal manufacturing, compressed air is used in large quantities in processes that include cooling, cleaning, cutting and shaping of metal parts. Without the proper compressed air supply and system, oil and moisture from ambient air can come into direct contact with metal surfaces, resulting in immediate material damage. Yet, many companies still fail to recognise the simple implementation and significant payoff of improving compressed air efficiency.

At Design Factory GmbH, a reliable supply of clean compressed air is needed for producing surface designs on stainless steel and non-ferrous metals. To ensure efficient polishing and blasting of its metal products, the plant is equipped with BOGE’s compressed air systems that generate compressed air with residual oil content of just 0.01mg/m3 and a pressure dew point of at least -25°C. This solution eliminates the presence of oil and moisture in the creative finishing process to produce polished stainless steel sheets, thus preventing expensive reworking procedures.

With the additional installation of a smart control that manages the compressed air systems’ energy consumption, Design Factory further benefits from round-the-clock visibility of its plant’s parameters. A user-friendly intuitive control, BOGE’s airtelligence provis anticipates the suitable compressor size and activates the corresponding machine even before the pressure limit is reached. By adjusting delivery volumes to the plant’s compressed air requirements and streamlining load and idle times, the intelligent system helps manufacturers maximise energy efficiency. The airtelligence provis can manage a network of up to 16 connected compressors and also offers a remote monitoring option that allows operators to access important data from any location and at any time.

“BOGE’s consumption-oriented technology ensures plant optimisation and smarter use of energy, especially as companies look to minimise the impacts of typically energy-intensive processes like metal manufacturing,” Mr Amunugama says.

Automation and Integration

For a growing number of businesses, self-optimisation extends beyond individual systems to include entire production sites. This, coupled with the move towards automation, has led to the creation of specially designed facilities that draw out the maximum capacity of manufacturing operations. Several features central to these smart factories are interconnected machines, data-sharing via cloud and artificial intelligence that drives preventive maintenance and self-diagnostics. The application of intelligence, such as sensors and robotics, along assembly lines also frees up manpower from repetitive tasks and directs resources to more urgent or complex roles.

In Oguchi, Japan, machine tool manufacturer Okuma Corporation operates two smart factories that leverage cutting-edge multitasking machines and advanced IIoT for high-mix, low-volume production. The industry-leading solution allows users to consolidate processes and affords them complete oversight of factory operations with real-time data analysis and seamless identification of parts. For metal manufacturers, these smart applications will enable mass customisation and shorter delivery times, improve overall productivity, and ensure flexibility amidst fluctuating demands.

Road to Digital Growth

New technologies in metal manufacturing are increasingly becoming a competitive differentiator as they deliver value, optimise production, reduce costs and improve safety. Businesses that successfully embed digital solutions into their business strategy and practices will no doubt help transform a mature industry that looks to improve operational efficiencies and play a bigger part in driving a green economy.

In Asia Pacific – the largest region in the global metal manufacturing market in 2017 – businesses are similarly recognising the importance of digitisation in enhancing execution and minimising waste across the supply chain. Broader implementations of tech-based innovations will simultaneously enable manufacturers’ to expand their capabilities and support the region’s growing metal consumption.

With the option of remote monitoring, BOGE's compressed air systems can be asessed in real-time to optimise energy efficiency.

Nike Ambassador 10