ENGEL has many years of experience in injection molding and the automation of injection-molding processes which are essential success factors when it comes to the cost-efficient production of large quantities of fiber-reinforced plastic (FRP) components. The latest milestone projects of ENGEl at Composites Europe 2017, which takes place this year in Stuttgart from September 19 to 21, highlight its technological advances.

At its Centre for Lightweight Composite Technologies in St. Valentin in Austria, ENGEL collaborates intensively with customers, partners and research institutions to accelerate the industrialisation of new processes. “Especially in lightweight composite engineering, it is vital for us as the machine tool manufacturer to collaborate closely with OEMs and tier suppliers,” emphasizes Peter Egger, Division Manager of the Centre for Lightweight Composite Technologies. “It guarantees that we keep our fingers constantly on the pulse, steer the right path, and customise our machines and systems to meet the specific requirements of industries such as automotive, teletronics or sporting goods.”

Noting that demand for integrated solutions from a single source is on the rise and given the increased in the degree of process integration and greater complexity of composite processes, the ENGEL Centre for Lightweight Composite Technologies focuses on all composite technologies currently in demand as well as advanced technologies ranging from HP-RTM and SMC, the processing of semi-finished thermoplastic products such as thermoplastic fabric and tapes, through to reactive technologies such as in-situ polymerisation (T-RTM).

organomelt launched in automotive series production

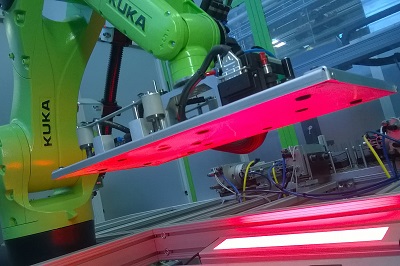

ENGEL recently addressed the processing and functionalization of continuous-fiber-reinforced thermoplastic semi-finished products (thermoplastic fabric) using the ENGEL organomelt process. The first major series applications of this technology in the automotive industry will be launched shortly. It was developed at ENGEL’s Centre for Lightweight Composites Technology and optimised for series production. ENGEL supplied two well-known tier suppliers with an integrated system. This technology is of particular interest to the automotive industry due to the use of thermoplastics, which significantly simplifies the recycling of production waste as well as end-of-life components.

Both of the recently delivered systems clearly show two distinct trends. Firstly, the additional integration of insert technology. In one of the applications, a large quantity of metal inserts is overmolded directly in the organomelt process. Secondly, the process involves thin-walled thermoplastic fabric with wall thicknesses of only 0.5 to 0.6 mm. This places different demands on the process than thicker materials. The heated semi-finished products must be processed very quickly so that they do not cool too much before shaping. ENGEL developed a vertical IR oven especially for this process. It is located directly above the clamping unit of the injection-molding machine. ENGEL covers the entire range of requirements for processing thermoplastic fabric by offering both vertical and horizontal IR ovens in various sizes. Both oven types were originally developed and manufactured by ENGEL and, just like ENGEL robots, they can therefore be fully integrated in the CC300 control unit of the injection-molding machine or press. This means that users can centrally monitor and control the entire processing method from the machine control unit, and the machine, robot and IR oven can automatically coordinate their work processes to achieve maximum efficiency.

Thermoplastic fabric has long been available, but thermoplastic tapes reinforced with glass fiber or carbon fiber are gaining importance. Usually tapes are only 0.14 to 0.3 mm thick, which is suitable for very few applications. As a result, layups consisting of up to 20 tape layers are produced and their design is part of the component structure. ENGEL has designed its own layup cell for tape layups, i.e. building layups directly upstream of the injection-molding process. Based on the pick-and-place principle, it works in sync with the injection-molding process. ENGEL also uses the technology in its own production. The robots of the e-pic series have a lightweight carbon arm which is produced at the ENGEL robot factory in Dietach, Austria using this new process. By using this innovative manufacturing technology, it was possible to reduce the weight of the robot rotational axis by 37 per cent. This gives the robot significantly higher dynamics and raises energy efficiency.

Reactive processing combined with injection molding

ENGEL is also one of the pioneers in the field of reactive processing where the aim is to increase the use of thermoplastic matrix materials. In 2012, ENGEL presented its first integrated concept for the in-situ polymerisation of ε-Caprolactam into polyamide directly in the mould in which a dry fiber preform is placed. ENGEL presented a near-production manufacturing cell at K 2016, and recently at the international automotive conference trend.scaut which took place in Austria in June of this year.

The cell combines in-situ polymerisation (T RTM) with the downstream functionalization of the FRP support structure in the injection molding process. “The automotive industry has shown great interest in this highly-integrated thermoplastic-based process and ENGEL is now prepared to collaborate with the industry to start component development.

The integrated, highly automated system concept is based on a v-duo press which ENGEL developed specifically for fiber-reinforced composition applications as well as multi-component processes with fiber preforms. The v-duo is a comparatively compact, energy-efficient machine that enables extremely cost-efficient manufacturing solutions. Its vertical clamping unit is accessible from all four sides instead of just two which simplifies automation.

Since it was launched in 2012, the v-duo series has been very successful in the automotive industry. For example, BMW uses a v-duo 3600 at its Landshut factory to produce large structural components from fiber-reinforced plastics using the HP-RTM process. The ENGEL machine has a clamping force of 36,000 kN. A v-duo 2300 is installed at Audi for the production of B-pillars. A v-duo 3600 was also supplied to the Open Hybrid LabFactory in Wolfsburg, Germany, to research functionally integrated composite technologies.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login