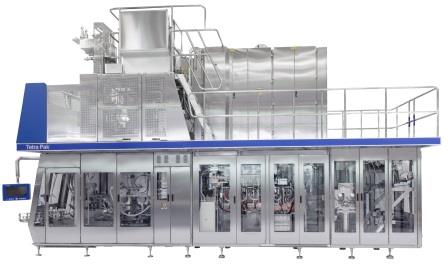

TETRA PAK has unveiled the Tetra Pak E3/Speed platform of filling machines at the Fispal Tecnologia International Trade Show in São Paulo, Brazil, which took place from 23-26 June.

The innovative equipment uses electron beams instead of hydrogen peroxide to sterilize packaging material, a first for the beverage carton industry. It can run up to 40,000 portion packages every hour and has lower operational costs than the existing Tetra Pak A3/Speed platform. The filling machine also boosts production flexibility and environmental performance.

The new filling machine has the potential to fill 40,000 portion packages in an hour. It saves manufacturers up to 20% in operational costs

Set for commercial release in 2016, the Tetra Pak E3/Speed will come in three versions, namely Tetra Pak E3/CompactFlex Extended Shelf Life, Tetra Pak E3/Speed Portion Packages, and Tetra Pak® E3/Flex Extended Shelf Life. Running at 15,000 packs per hour, the machine produces family packages of Tetra Brik (R) Aseptic 1000 Edge with LightCap (TM) 30. Its modular design allows more production flexibility as manufacturers can switch between pasteurized and extended shelf life (ESL) production orders on the same E3/CompactFlex filling machine simply by installing an eBeam kit.

Electronic beam (eBeam) sterilization technology developed by Tetra Pak in collaboration with COMET, eliminates the use of hydrogen peroxide. Among its benefits is easier water recycling

The Tetra Pak E3/Speed adopts eBeam sterilization technology developed in collaboration with COMET, a global leader in high-voltage and high-vacuum technology. The technology focuses a controlled beam of electrons onto the surface of the packaging material as it runs through the filling machine to kill any bacteria or microorganism. This helps remove the hydrogen peroxide sterilization process, which slows down carton packaging speed.

The use of eBeam technology helps achieve speeds of up to 40,000 portion packs per hour or 11 packs every second. The greater capacity can save beverage manufacturers up to 20% in operational costs. Meanwhile, the elimination of hydrogen peroxide sterilization makes water recycling easier and reduces energy consumption and wastes.

Watch the video.

Zoom Kobe XI ZK11