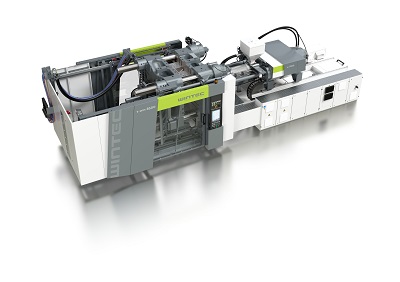

With a focus on productivity, quality and energy efficiency, WINTEC builds injection molding machines tailored to the requirements of standard applications. At the Koplas 2017, from March 7 through March 11, in Goyang, South Korea, with the production of engine components on a t-win machine, the subsidiary of the Austrian ENGEL Group demonstrates how quality can be combined with efficiency.

Since their market introduction three years ago, the hydraulic injection moolding machines of the t-win series have become well established on Asian markets in such fields as automotive, domestic appliances and white goods. WINTEC machines are used for high-volume standard applications which, although not requiring specialist technology, nonetheless place high demands on quality and process stability.

At the WINTEC exhibition booth, with the production of oil deflectors, the performance and reliability of the series is demonstrated by a t-win 6500-3300 injection molding machine. In a 2-cavity mold, the engine components are produced out of PA 66. The shot weight per cavity is 200 grams.

In addition to the design features of the machine, the integrated handling also contributes to the high process consistency and efficiency. An ENGEL viper 20 linear robot will extract the parts from the mold and place them on a conveyor belt.

The C2 control unit of the t-win machines offers ample flexibility in terms of connecting robots of various types and brands. The C2 is characterized by intuitive operation, which reduces the risk of operator error. The entire machine status is displayed on a clear-cut single screen. A quick adjustment page groups the most important setting parameters in a compact way. To ensure an ergonomic workflow, the 15" touchscreen can be swiveled out forward and is height adjustable. In terms of processing power, the C2 control unit outperforms control units of other machine producers in this market segment by 33 percent.

60% reduction in energy consumption

Even in the standard version, the t-win machines are already equipped with the servowin servo-hydraulics which reduces energy consumption by more than 60 percent compared to conventional hydraulic injection molding machines. Additional factors that contribute to a high degree of energy efficiency are the operating point optimization and the dual-platen design of the clamping unit with low moving masses and exposed tie-bars. The linear guidance of the movable mold mounting platen reduces friction and keeps the mold area free of lubricating oil.

The dual-platen clamping unit was developed in Europe and guarantees maximum platen parallelism throughout the machine’s service life, which results in sensitive mold protection, excellent dynamics and short dry cycle times. Parallel auxiliary movements such as the ejector, core pulls, or jets, are optional possibilities.

Rapid on-site service for high availability

Opened in 2014, the WINTEC plant in Changzhou, China, is integrated into the global quality management of the ENGEL Group. Accordingly, the same stringent quality standards apply as in the Austrian parent plant, with the objective of constructing high quality, reliable, and durable injection molding machines. Besides quality, service performance is an important deciding factor for WINTEC's customers. Sales and service have been decentralized and distributed throughout Asia in order to be rapidly on-site at all times, thus further increasing the availability of WINTEC injection molding machines. WINTEC machines are available in selected developing markets, primarily in Asia. WINTEC at Koplas 2017 is located at hall 5, booth P650

Highsnobiety Sneakers

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login