AT IFFA 2016, the vacuum technology specialist, Busch oriented visitors where energy-saving potential in vacuum packaging exists and how this potential can be used. The company says the vacuum supply must be analyzed together with the entire packaging process, and all parameters must be optimally suited to fit one another. For this, Busch offers an audit service called “VacuumAudit” for achieving optimum energy efficiency for the packager. During this VacuumAudit, the current state is evaluated and suggested solutions are developed for the customer.

Launched at IFFA 2016, the R 5 RD 0360 A is the first size of new, energy-efficient rotary vane vacuum pumps from Busch

Vacuum supply

The vacuum pump is the core of a packaging machine's vacuum supply. At the trade show, Busch unveiled the R 5 RD vacuum pump, a new design that uses 20 percent less motor power than the previous models. This vacuum pump is based on rotary vane technology that has been proven through decades of use and was further optimized to make these energy savings possible. For example, if a thermoforming packaging machine is equipped with the new R 5 RD 0360 A, the annual electricity costs saved during two-shift operation at ten cycles per minute with a chamber volume of 20 liters are €850 or US$948 (price of electricity = 0.18 euros/kWh).

Reducing thermal load

As a general rule, vacuum pumps generate waste heat that can negatively affect production and processing rooms or their air-conditioning systems. This waste heat can be drastically reduced as well as utilized.

An oil/water heat exchanger on an R 5 rotary vane vacuum pump can significantly reduce waste heat and thus reduce the energy costs for air conditioning. Furthermore, the heat exchanger can be used to generate warm water, which can in turn be used as warm water during operation. R 5 rotary vane vacuum pumps can be retrofitted with heat exchangers.

If four packaging machines operate in one packaging room and each is fitted with an R 5 rotary vane vacuum pump with 5.5 kW of motor power, the energy required for cooling is approximately 6.0 kW. If the vacuum pumps are operated with a heat exchanger, the energy requirement for cooling is reduced to approximately 1.5 kW. During an operating time of 4,500 hours/year and an assumed electricity price of 0.18 euros/kWh, this results in annual energy cost savings of approximately €5,000 (US$5576)

The use of warm water is not taken into account in this example.

Busch central vacuum system as seen in a large meat processing business

Central vacuum supply

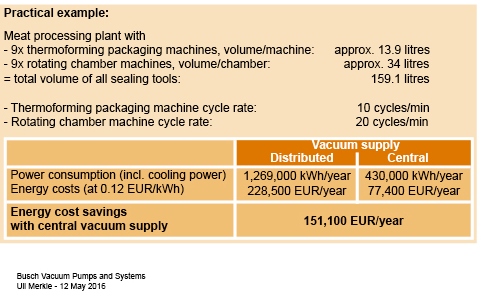

A company that packages foodstuffs on several thermoforming packaging machines, tray sealers or chamber machines should consider using a centralized vacuum supply. Being the largest manufacturer in the world of these kinds of centralized vacuum systems, Busch says it has the most experience. With centralization, energy cost savings of 50 percent and more can generally be expected. This is possible because fewer vacuum pumps are required for this than for a decentralized vacuum supply. Furthermore, performance control can be precisely adjusted to fit the requirements of overall operations. Normally, not all packaging machines run at peak load, so all of the vacuum pumps are not always in operation. Also, centralized vacuum systems offer maximum reliability and safety as all systemically relevant components have a redundant design. If a vacuum pump fails or needs maintenance work, full vacuum power remains intact. Busch central vacuum systems can be equipped with various vacuum pumps. In addition to oil-lubricated R 5 rotary vane vacuum pumps, dry Mink claw vacuum pumps or COBRA screw vacuum pumps can also be used as components. The investment costs can be reduced during purchasing by including already existing vacuum pumps in the system installation. Figure 3 demonstrates one practical example. In the process of centralizing the vacuum supply, one manufacturer of meat products realized energy savings of €151,000 (US$169,000) per year.

Comparison of energy costs for central and local vacuum supply

Nike Kevin Durant