The global thermoplastic vulcanizates (TPV) market is expected to reach $1.87 billion by 2020, according to a report by Grand View Research, Inc. Rising demand for lightweight, high performance materials from automotive industry is expected to drive the global TPV market which has been benefiting from the trend where metals are increasingly being replaced by lighweight plastic materials. Over dependence on fossil fuels coupled with the diminishing hydrocarbon reserves is expected to bolster the drive for automobile fuel efficiency which has further propelled the growth of engineering plastics.

Such a trend is expected to complement the TPV market over the next few years. Natural rubber substitution across various end-use industries is also expected to have a positive influence on the market growth. TPVs are usually a blend of dispersed rubber particles in a thermoplastic matrix, thus rendering combined elastomer and thermoplastic properties to the material. Typically, TPV contains about two-thirds of ethylene propylene diene monomer (EPDM) and the rest of impact polypropylene. There are other raw material combinations as well, such as polypropylene & natural rubber (PP/NR), butyl, halobutyl & polypropylene, polypropylene & EPDM (PP/EPDM), polyolefin blends & EPDM and polypropylene & ethylene octene copolymer (PP/EOC). EPDM based TPV are expected to witness strong demand in the future and penetrate conventional markets for thermosetting EPDM applications.

Automotive is the largest application segment accounts for over half of total TPV market volume. Superior characteristics over conventional materials such as low weight, high strength, abrasion resistance, and flexibility make the product a key substitute for the conventional materials used in the multiple end-use industries. Combined vulcanized rubber and thermoplastic characteristics have propelled TPV to become an evident choice for the end-use industries such as automotives, healthcare and industrial & consumer goods.

Asia Pacific is expected to overtake North America to become the leading regional TPV market, growing by more than 7%, the highest rate compared to other regions. Rapid industrialization in emerging economies of India, China, and Indonesia is expected to drive the regional TPV market.

High-flow TPVs for auto parts

A new series of TPV elastomers with key advantages over standard TPVs in their natural or uncolored form provides the appearance and tactile properties valued for automotive interiors while also exhibiting excellent colorability for exterior components.

Unlike many standard TPVs in their natural form, Sarlink® 6700 Series compounds from Teknor Apex Company have a very light hue that makes them easier to custom-color, do not require drying prior to processing, and are UV-stabilized to meet auto-industry specifications for interior components. The new TPVs are low-fogging and exhibit high flow for molding complex parts with thin walls. Recommended interior applications include floor mats, bin mats, cup-holder liners, and “soft-touch” grips, knobs, and buttons. When colored with UV-stabilized masterbatch, Sarlink 6700 Series compounds also can be used for exterior parts such as cowl vent seals, mirror and antenna gaskets, headlight bezels, and window trim.

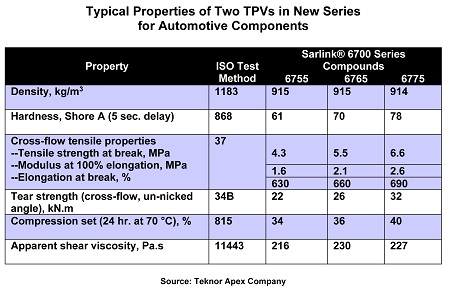

Compounds in the new series are resistant to aqueous solutions, exhibit good thermal stability, and are available, in natural form only, in Shore A hardnesses from 55 to 75. (See table for property data.)

Sarlink TPVs have received automotive approvals from General Motors (GMW-15816), Ford (WSS-M2D510-A5-A7), and Chrysler (MS-AR-100-AMV2, -BMV2, and CMV2), according to Jeffrey E. Dickerhoof, senior sales and marketing manager for the Thermoplastic Elastomer Division of Teknor Apex.

Compra Zapatillas de running para hombre