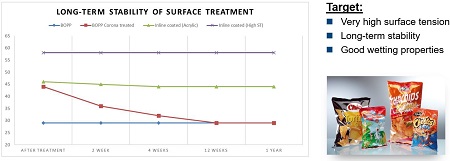

Many film properties are directly related to the surface characteristics and chemical constitution of the outer layer. Especially for polyolefine-based materials, a further converting step is not purposeful without a suitable surface treatment (e.g. corona, flame or plasma). By using one of these “state-of-the-art” technologies, it is possible to increase the surface tension – but the treatment level is limited and only temporary. In order to develop novel treatment methods for BOPP, several years ago Brückner started to invest in inline coating developments to provide solutions for customers.

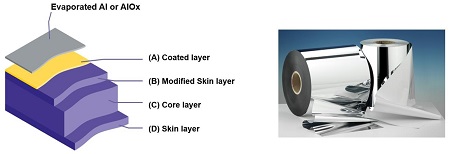

Layer structure: Inline coated BOPP for improved properties after metallisation

A newly developed method to ensure a long-term stable surface treatment is the BOPP inline coating technology. By using the right coating materials, many properties like metal bonding, ink adhesion and barrier values can be significantly improved. Compared to the coating technology of polyester films, which is already widely established in the market, the coating process for BOPP is much more complicated due to the high stretching ratios, film temperatures and the chemical constitution of polypropylene films. A lot of effort and resources were invested to figure out the right material combinations and machine settings to develop new film types with improved properties.

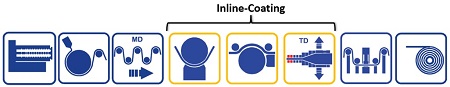

Coating steps between MD- and TD-stretching (Corona, Coating and Drying)

Compared to the existing offline coating process for BOPP films, the coating step takes place between the MD- and TD-stretching. This means that after TD stretching, the whole film width is already coated with a very thin and homogeneous layer. Additional handling, storing and coating steps are no longer necessary. The resulting layer thickness of this chemical treatment is in the range of 100 nm, and more than sufficient for most applications like printing, metallising and lamination processes. For the purpose of packaging and printing the wetting properties can be ensured for water-based and solvent-based ink formulations. Even for UV printing, the surface can be chemically treated to ensure improved bonding between the film surface and the inks with the inline coating process.

Different treating methods: Inline coated films without any decay over time

When it comes to barrier applications (e.g. crisps, coffee and other dried goods), the interface between the polymeric film and the evaporated inorganic layer definitely needs a certain treatment to ensure the necessary bonding between the molecules. Currently the standard metallised BOPP film is corona treated to achieve the required bonding. In comparison to this, our BOPP coating technology (patent pending) offers a significantly higher metal adhesion in addition to improved barrier properties due to the used material combinations and advanced application methods.

The unique pilot line from Brückner is equipped with a versatile coating unit to apply and evaluate coating materials on different polymeric surfaces. The process has been constantly optimised during the last years to find the right machine settings and barrier coatings to ensure a stable process with improved properties.

After several internal and external film evaluations, in 2018 this technology was successfully integrated into a full size BOPP production line. This technology is also able to add value to existing lines due to the higher sales price of inline coated films.

Brückner offers a complete knowledge package for the inline coating process of polypropylene films. It contains the required material recommendation, the necessary surface modification and machine settings. Together with the advanced and field tested coating equipment, Brückner delivers a reliable solution from one single source. The coating equipment can also be integrated for upgrades in the existing production line to enrich the product portfolio and make it more profitable. The requirements and limitations for upgrade packages depend on the space between MDO and TDO and the thermal layout of the preheating zone. By using equipment and material recommendation from Brückner, the customer will produce sellable film shortly after start up.

- The author, Willi Lindemann, is the R&D Engineer – Inline Coating Technology at Brückner.

Womens Nike Cortez

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login