Emtelle is one of the leading players in the telecommunications industry. It produces pipeline communication network solutions worldwide, as well as micro and mini cables which can be blown in, thus combining under one roof the core competencies of developing and manufacturing plastic pipes with the production of blown-in fiberglass cables.

Emtelle has widened its product portfolio that its Danish plant in Sønder Felding now turns out pressure pipes for water transport. To meet customers’ orders promptly and without large inventory, the pipe manufacturer decided to purchase a complete FDC pipe extrusion line from battenfeld-cincinnati to replace an existing, less flexible line.

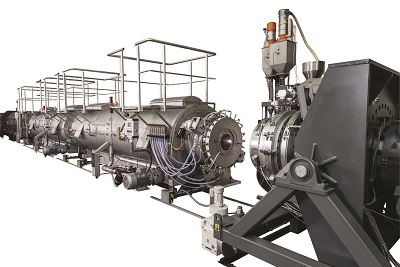

The greatest advantage of the new line is its enormous flexibility, according to Kenn E. Byllemos COO of Emtelle Denmark. The line is a 4-layer co-extrusion line with four extruders and a co-extruder for color stripes, which also includes two FDC calibration sleeves and a complete set of FDC downstream equipment. In this way, diameters ranging from 200 to 800 mm can be handled by a single line, which is unique in the industry. The smaller of the automatic calibration sleeves handles diameters from 200 to 355 mm, the larger diameters from 400 to 630 mm. Diameter ranges from 710 to 800 mm can be handled with standard calibration sleeves.

“In contrast to competitors’ products, our calibration sleeves are made of a cylindrical, rolled metal sheet that comes close to a standard calibration in its design. The pipe dimension can be changed during production – seamlessly and fully automatically. Both standard and customized sizes can be produced with our calibration sleeves, not only in terms of external diameters but also in terms of wall thicknesses, which may vary for example between 6.3 and 57.2 mm”, explains Brigitte Diekhaus, Project Leader at battenfeld-cincinnati.

The fully automatic dimension change was a very important consideration for Emtelle, since more customers are demanding customized sizes, for example cap pipes. These must combine a very small wall thickness with a relatively large external diameter, according to Byllemos. “In practice, changeover to different pipe dimensions takes us 20 min at most and changing to a different automatic range – e.g. from 200 – 355 mm to 400 – 630 mm can be effected within one shift. Another decisive advantage is that only very minor quantities of scrap are produced during dimension change”, are further reasons given by Byllemos for his decision to choose the FDC system from battenfeld-cincinnati.

For better results in color change, a radial distributor for the outer layer is integrated in the adjustable melt gap, so that the color change can be carried out quickly and with relatively little material for purging the outer layer channel.

Automatic dimension change and consequently the high flexibility of the line as a whole is finally also ensured by the FDC downstream components, which are also a unique feature in the industry. The vacuum tank operates with a pipe support system covering 180° of the pipe’s circumference and is steplessly adjustable over the entire dimensional range without modifications. This also applies to the haul-off and cutting device, which can be adjusted automatically during dimension change as well.

In close cooperation between the processor and the machine manufacturer, the haul-off has been designed to prevent deformation of customized pipes with small wall thicknesses. To achieve the automatic changeover without any problems or human intervention, the battenfeld-cincinnati specialists have also extended the extruder control system in an optimal way, so that the changeover of all components can be effected at the push of a button. This type of fully automatic operation was also a decisive argument for Emtelle in favor of the line from battenfeld-cincinnati.

Air Jordan IV 4 Shoes

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login