A MAJOR challenge for the food industry is how to handle a large number of different product recipes all within the context of achieving high standards of hygiene, minimizing product waste, reducing energy consumption and keeping manpower costs low.

This was the challenge that faced BOH Plantations Sdn Bhd, a market-leading tea grower in Malaysia who account for 70 percent of all tea produced in Malaysia. They were the first tea company in the world to be accredited with ISO 22000 certification for complying with the worldwide food safety standard. BOH Plantations realized that investment in their manufacturing process was required to achieve and maintain exemplary hygienic manufacturing and quality standards in the production of their 3-in-1 Instant Tea Mixes.

The manufacturing operation needed to allow simultaneous multiple recipe production, with quick changeovers and clean-downs. However, BOH wanted to use their existing floor-space for this new production area and wished to have the ability to expand in the future.

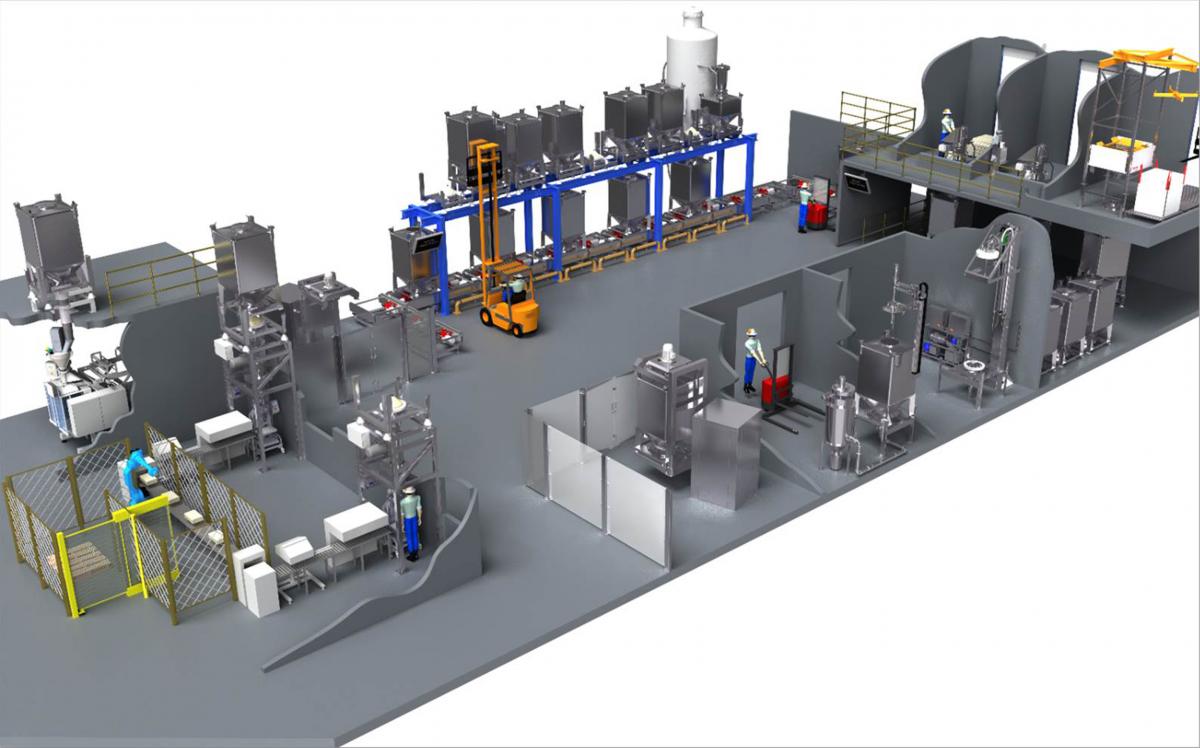

An example layout for factories that handle powder products

For help in these criteria, they looked to Matcon for solutions. The recommendation was to install a flexible and future-proof powder processing system using Intermediate Bulk Containers (IBCs). This enables “parallel” or “flow” processing, whereby all the different process steps are no longer coupled together, but are undertaken simultaneously; no more waiting for each other to be completed before moving to the next. Because the powder moves between the decoupled production steps in IBCs, product flows smoothly around the system and processes are continuously fed giving good Overall Equipment Effectiveness (OEE) rates.

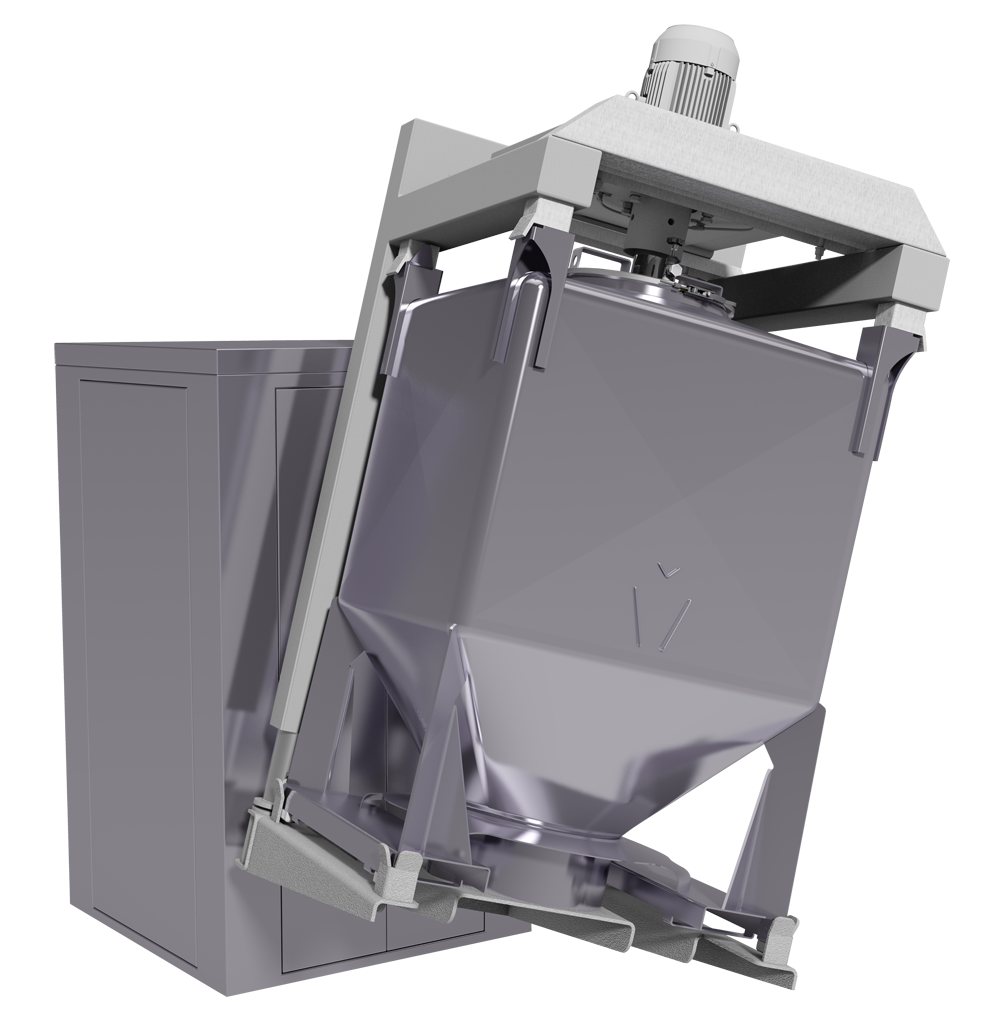

IBC blender

At the heart of the system, reliable, IBC in-bin blending means that recipe changeover is instantaneous as product is mixed within the IBC itself and does not come into contact with the Blender. In fact, a number of different recipes can run throughout the process at the same time without risk of cross-contamination as the system remains closed at all stages. In BOH’s case, the small footprint of the Blender also meant that the new IBC system fitted neatly into the space allowed, with room for expansion.

Cleaning of the IBCs is done off-line and cleaning of the filling and packing equipment is quick and efficient with change-out parts available to make the cleaning operation even quicker.

Lean benefits of a Matcon IBC system:

- Reduced cost per kg of manufactured product

- Improved yield from the equipment, less space needed to produce more

- Producing smaller batches to order

- Flexibility to accommodate a variety of recipes

- Decreased inventory, for improved cash utilization

With Matcon IBCs, the unique Cone Valve technology within each one both promotes mass-flow of the powders, protecting against segregation, and prevents bridging and blocking. In conjunction with the Matcon Discharge Station, all recipes are fed to down-stream processes in a controlled manner. This means that the refilling of the feed hopper is reliable and steady, keeping a uniform product bulk density in the infeed hopper, which helps to maintain both the accuracy and speed of the downstream equipment.

With the Matcon IBC system, BOH Plantations Sdn Bhd has been able to achieve a fully flexible manufacturing facility, maximizing their throughput with the minimum of equipment investment.

Matcon have over 35 years’ experience of supplying IBC systems around the world, across a range of food sectors including infant & sports nutrition, food flavorings, beverages and bakery. If you would like to find out how a flexible, agile IBC system might benefit your business, email the company at matcon_marketing@idexcorp.com or call +44 1386 769000.

Zapatillas Trail Running