Whether in daily manufacturing or the development of new processes and products: surfaces and their properties are playing an increasingly important role in nearly all industrial areas. The surfaces of the materials employed often have to be pre-treated in order that additional properties may be imparted which will qualify them for further application areas. Open-air plasma is a method of producing new surface properties and optimising existing manufacturing processes. The open-air plasma, applied by special nozzles, effects micro-fine cleaning and extensive activation of all kinds of surfaces and leads to optimum adhesion of coatings, paints and adhesives, such as the epoxy adhesives and hotmelts frequently used in electronics. The process permits continuous in-line application to all or only some parts of the surface at high speeds. If the nozzle is guided by a robot, high-precision localised effects can be obtained and the finest contours cleaned, activated and coated. Pretty often, a material cannot be used until its surface has been custom treated with open-air plasma.

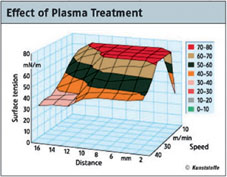

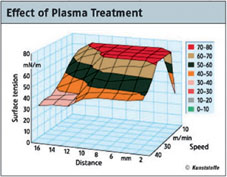

Electrically neutral plasma beam The systems, which are based on a nozzle principle, work at atmospheric pressure and produce a plasma with the aid of an arc ignited in the nozzle and the air which serves as working gas. The plasma then flows potential-free onto the product to be treated . It possesses sufficient numbers of excited particles to introduce targeted effects onto the surface (Fig. 1). A special feature is the fact that the emitted plasma beam is electrically neutral, and this greatly extends and simplifies applicability. Its intensity is so high that processing speeds of several 100 m/min are possible. The heating typically undergone by plastic surfaces is less than 20℃ during treatment. The open-air system works in three ways: it activates the surface by targeted oxidation processes, discharging the surface at the same time and leading to micro-fine cleaning. The nozzle systems employed can be integrated in-line into new or existing production lines. The process of surface discharge means that the open-air plasma system offers cleaning effects which far exceed those of conventional systems. Here, the user is benefiting from the high electrostatic discharging effect of a free plasma beam. This effect is additionally boosted by the very high emission speed of the plasma, as a result of which loosely adhering particles are also effectively removed from the surface.

Whether of metal or plastic, the geometries of work pieces are becoming increasingly sophisticated. The fact that the tips of the plasma nozzle can be readily adapted to the work piece geometry opens up a broad range of applications. This adaptability is crucial for pre-treat- ment of highly complex, three-dimensional geometries with a large number of undercuts.

Plasma in automotive electronics Electronic parts play an increasing role in automotive manufacture as most innovations are electronics-based. Major automotive subcontractors use open-air plasma to protect their highly sensitive sensors and control elements. These perform important tasks, such as managing the engine and air-conditioning, regulating the braking and chassis systems and controlling the lighting system. The IEC standard and the IP degrees of protection stipulate that the sensors and control elements must be protected against penetration by moisture and contamination. Automotive electronics are exposed to various risks, and so the requirements on the integrity of the protective plastic housing are high: the electronics must withstand temperature fluctuations of -40℃ to 140℃ in the test process and all moisture, liquids and chemicals must be kept at bay. With a view to achieving the best-possible seal, it is standard practice to treat the adherends of electro

NEW BALANCE Whether in daily manufacturing or the development of new processes and products: surfaces and their properties are playing an increasingly important role in nearly all industrial areas. The surfaces of the materials employed often have to be pre-treated in order that additional properties may be imparted which will qualify them for further application areas. Open-air plasma is a method of producing new surface properties and optimising existing manufacturing processes. The open-air plasma, applied by special nozzles, effects micro-fine cleaning and extensive activation of all kinds of surfaces and leads to optimum adhesion of coatings, paints and adhesives, such as the epoxy adhesives and hotmelts frequently used in electronics. The process permits continuous in-line application to all or only some parts of the surface at high speeds. If the nozzle is guided by a robot, high-precision localised effects can be obtained and the finest contours cleaned, activated and coated. Pretty often, a material cannot be used until its surface has been custom treated with open-air plasma. Electrically neutral plasma beam The systems, which are based on a nozzle principle, work at atmospheric pressure and produce a plasma with the aid of an arc ignited in the nozzle and the air which serves as working gas. The plasma then flows potential-free onto the product to be treated . It possesses sufficient numbers of excited particles to introduce targeted effects onto the surface (Fig. 1). A special feature is the fact that the emitted plasma beam is electrically neutral, and this greatly extends and simplifies applicability. Its intensity is so high that processing speeds of several 100 m/min are possible. The heating typically undergone by plastic surfaces is less than 20℃ during treatment. The open-air system works in three ways: it activates the surface by targeted oxidation processes, discharging the surface at the same time and leading to micro-fine cleaning. The nozzle systems employed can be integrated in-line into new or existing production lines. The process of surface discharge means that the open-air plasma system offers cleaning effects which far exceed those of conventional systems. Here, the user is benefiting from the high electrostatic discharging effect of a free plasma beam. This effect is additionally boosted by the very high emission speed of the plasma, as a result of which loosely adhering particles are also effectively removed from the surface.

Whether in daily manufacturing or the development of new processes and products: surfaces and their properties are playing an increasingly important role in nearly all industrial areas. The surfaces of the materials employed often have to be pre-treated in order that additional properties may be imparted which will qualify them for further application areas. Open-air plasma is a method of producing new surface properties and optimising existing manufacturing processes. The open-air plasma, applied by special nozzles, effects micro-fine cleaning and extensive activation of all kinds of surfaces and leads to optimum adhesion of coatings, paints and adhesives, such as the epoxy adhesives and hotmelts frequently used in electronics. The process permits continuous in-line application to all or only some parts of the surface at high speeds. If the nozzle is guided by a robot, high-precision localised effects can be obtained and the finest contours cleaned, activated and coated. Pretty often, a material cannot be used until its surface has been custom treated with open-air plasma. Electrically neutral plasma beam The systems, which are based on a nozzle principle, work at atmospheric pressure and produce a plasma with the aid of an arc ignited in the nozzle and the air which serves as working gas. The plasma then flows potential-free onto the product to be treated . It possesses sufficient numbers of excited particles to introduce targeted effects onto the surface (Fig. 1). A special feature is the fact that the emitted plasma beam is electrically neutral, and this greatly extends and simplifies applicability. Its intensity is so high that processing speeds of several 100 m/min are possible. The heating typically undergone by plastic surfaces is less than 20℃ during treatment. The open-air system works in three ways: it activates the surface by targeted oxidation processes, discharging the surface at the same time and leading to micro-fine cleaning. The nozzle systems employed can be integrated in-line into new or existing production lines. The process of surface discharge means that the open-air plasma system offers cleaning effects which far exceed those of conventional systems. Here, the user is benefiting from the high electrostatic discharging effect of a free plasma beam. This effect is additionally boosted by the very high emission speed of the plasma, as a result of which loosely adhering particles are also effectively removed from the surface.  Whether of metal or plastic, the geometries of work pieces are becoming increasingly sophisticated. The fact that the tips of the plasma nozzle can be readily adapted to the work piece geometry opens up a broad range of applications. This adaptability is crucial for pre-treat- ment of highly complex, three-dimensional geometries with a large number of undercuts. Plasma in automotive electronics Electronic parts play an increasing role in automotive manufacture as most innovations are electronics-based. Major automotive subcontractors use open-air plasma to protect their highly sensitive sensors and control elements. These perform important tasks, such as managing the engine and air-conditioning, regulating the braking and chassis systems and controlling the lighting system. The IEC standard and the IP degrees of protection stipulate that the sensors and control elements must be protected against penetration by moisture and contamination. Automotive electronics are exposed to various risks, and so the requirements on the integrity of the protective plastic housing are high: the electronics must withstand temperature fluctuations of -40℃ to 140℃ in the test process and all moisture, liquids and chemicals must be kept at bay. With a view to achieving the best-possible seal, it is standard practice to treat the adherends of electroNEW BALANCE

Whether of metal or plastic, the geometries of work pieces are becoming increasingly sophisticated. The fact that the tips of the plasma nozzle can be readily adapted to the work piece geometry opens up a broad range of applications. This adaptability is crucial for pre-treat- ment of highly complex, three-dimensional geometries with a large number of undercuts. Plasma in automotive electronics Electronic parts play an increasing role in automotive manufacture as most innovations are electronics-based. Major automotive subcontractors use open-air plasma to protect their highly sensitive sensors and control elements. These perform important tasks, such as managing the engine and air-conditioning, regulating the braking and chassis systems and controlling the lighting system. The IEC standard and the IP degrees of protection stipulate that the sensors and control elements must be protected against penetration by moisture and contamination. Automotive electronics are exposed to various risks, and so the requirements on the integrity of the protective plastic housing are high: the electronics must withstand temperature fluctuations of -40℃ to 140℃ in the test process and all moisture, liquids and chemicals must be kept at bay. With a view to achieving the best-possible seal, it is standard practice to treat the adherends of electroNEW BALANCE