OPTIMISING total cost of ownership is very important to manufacturers even in the dairy industry, and this is one of the reasons GEA developed a new high-pressure pump for reverse osmosis and nanofiltration. The hygienic pump is designed for system pressures up to 64 bar, even way above the needs of the dairy industry, and it also meets international standards.

The new high-pressure pump is based on the company’s “HYGIA” premium range of hygienic pumps suitable for viscous fluids and applications as a result of its high surface quality and adaptability. It is designed to pump fluids as well as homogeneous media containing air or gas and withstands a system pressure of 64 bar.

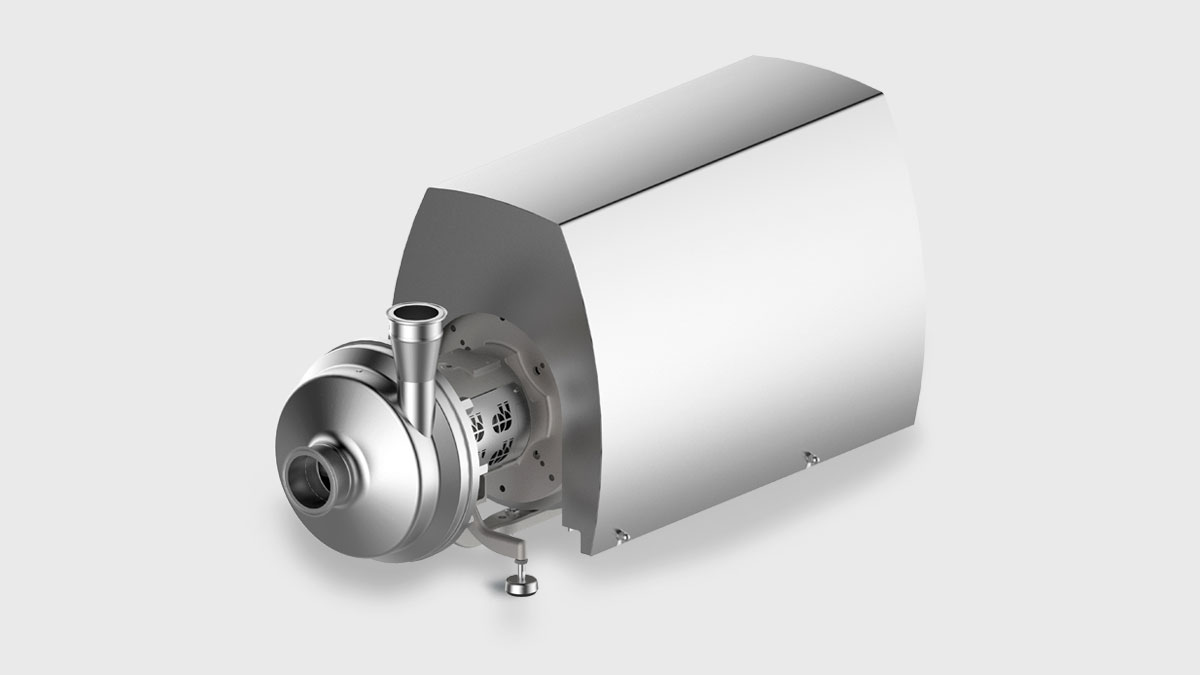

GEA Hilge HYGIA H hygienic high-pressure pump for membrane filtration.

“40 bar is standard in the dairy industry”, says Martin Zickler, product manager for hygienic pumps at GEA. “With a 64 bar system pressure, the successful line of pumps can now cover the high pressure ranges required for membrane filtration in whey processing, meaning even more valuable substances can be extracted.” Producers are increasingly attaching importance to this because modern membrane processes significantly increase the value added in fractionation and concentration of whey and milk protein.

GEA's pump specialists have been concentrating mainly on beverages; however, the focus is now turning to dairy applications. “GEA already has a wide range of solutions in this segment. The new high-pressure pump closes a gap in our product range, and now enables us to tailor complete membrane filtration solutions to our customers.” It is available in two sizes, of which the large variant—powered by a 45 kilowatt motor—delivers a volume flow of up to 200 cubic meters per hour and reaches a maximum delivery height of 72 meters.

A forged casing design facilitates proper cleanability

To facilitate cleanability for hygienically sensitive applications—such as in milk processing—GEA opts for a forged casing instead of a cast metal casing for product-wetted components. “Cast metal alternatives are undesirable—especially in the pharmaceutical industry—because of the surface cavities. Cleanability is affected and the 3-A certification is not easily obtained,” says Mr. Zickler. However, both cleanability and 3-A certification were important parameters for GEA in the development of the pump. All materials have therefore been carefully selected for use in hygienic processes. The casings are made of forged CrNiMo (1.4404) and have a nonporous and cavity-free surface.

Adapta motor connection with additional value

GEA has designed the Hilge HYGIA H to use the flexible Adapta motor connection: It enables the pump to remain in the pipeline when the motor needs to be replaced. The entire system does not need to be re-sterilized or cleaned. “Experience has shown that customers choose an Adapta motor connection when the demands are particularly high. In the pharmaceutical industry—where cleaning time and effort has a massive impact—the percentage has already reached 80 to 90 percent. The demand for flexible, cost-saving solutions is also increasing significantly in the food industry”, adds Mr. Zickler, explaining why GEA also uses this bearing bracket for its new high-pressure pump.

Thanks to the modular design of the Adapta motor connection, the pumps can be equipped with a wide variety of standard motors, allowing them to easily meet all country-specific requirements for electric motors. This will also make the GEA Hilge HYGIA H attractive to foreign markets: “Customers in the US are now able to connect their own Nema motors,” says Mr. Zickler. “We can deliver the pumps without motor, which means that the plant manufacturer can simply place the pumps in the warehouse. A suitable motor is mounted depending on the country in which they will be used.”

The GEA Hilge HYGIA H was first introduced at Anuga Foodtec 2018 – Source: GEA

Nike Air VaporMax

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login