ONE can hardly open a newspaper without coming across stories describing the global epidemic - obesity. Sugar and fat - together with over consumption, are often mentioned as the two most important factors causing overweight and the intake hereof should be controlled. Together with cakes and confectionary products, ice cream is included in the food category of which nutritionists recommend a decreased intake. Ice cream is traditionally produced with 8-10% of fat and approximately 15% of sugar. Lowering the level of fat has until now caused decreased eating quality expressed as less creaminess, body and smoothness. Today's consumers do not accept this. For healthier alternatives to become successful, the eating quality should be at least at same level as standard products. Creamy yet low fat Fat reduct ion in ice cream has traditionally influenced the sensory qualities of the product negatively. A creamy and smooth sensation has been difficult to maintain, and the melting of the ice cream would appear faster than for a similar product with standard fat content. Creaminess is determined by a complex interaction between the raw materials, the composition of the recipe, and the production process. Creaminess is mainly defined by the distribution of air bubbles in the end product - a phenomenon in which emulsifiers, in particular, play an important role. Traditionally, a certain fat content has been required in order to create a fat globule network surrounding and stabilising the air cells. To allow for significant fat reductions in ice cream, Palsgaard has developed an emulsifier system that adds an extremely smooth and creamy sensation to ice cream and allows for significant fat reductions without compromising on neither the sensory characteristics nor the melting profiles and heat shock stability.

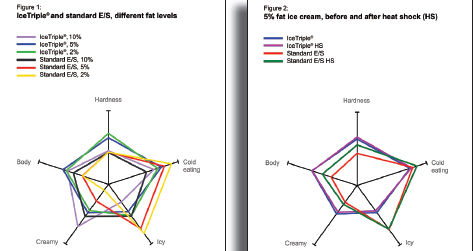

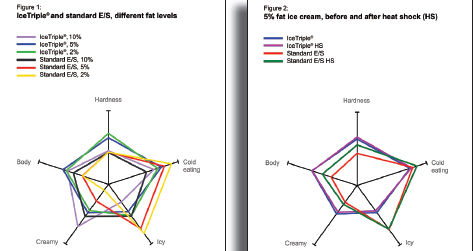

The solution, Palsgaard IceTriple®systems (patent pending), are fully integrated emulsifier-stabiliser compounds based on propylene glycol esters of fatty acids (PGMS) E 477, and mono-diglycerides E 471, combined with various hydrocolloids, in accordance with local and individual requirements. This breakthrough in ice cream technology is also available in trans fat free versions. Figures 1 and 2 provide a graphic illustration of the sensory profile. Alternative solutions? The latest generation of ice cream freezers makes it possible to extrude at very low temperatures. This has improved the churning and consequently the creaminess and smoothness of the final product, as well as positively influenced the melting resistance. However, although the initial size of the ice crystals is relatively small compared to traditional freezing techniques, ice crystals will still grow during storage time. There is no evidence that heat shock stability is improved through low-temperature freezing, which makes this technique less appealing. Another means of improving the heat shock stability is the use of anti-freeze proteins. However, anti-freeze proteins are not easily obtainable and certain legal issues regarding their application must be observed. Conventional emulsifiers and stabilisers have been applied in ice cream production for many years. They are important in terms of fine-tuning the sensory profile of the product, and also retard the growth of ice crystals. However, they cannot endure repeated temperature fluctuations. Excellent heat shock stability The IceTriple system offers excellent heat shock stability for ice cream. This ensures a pleasant texture and mouth feel even after repeated exposure to fluctuating temperatures. In most parts of the world, ice cream is exposed to fluctuating temperatures before consumption, which in most cases will damage its texture, mouth feel and appearance. The risk of damage to the ice cream is enhanced when the recipe is reduced in

Nike Hyperdunk 2018 ONE can hardly open a newspaper without coming across stories describing the global epidemic - obesity. Sugar and fat - together with over consumption, are often mentioned as the two most important factors causing overweight and the intake hereof should be controlled. Together with cakes and confectionary products, ice cream is included in the food category of which nutritionists recommend a decreased intake. Ice cream is traditionally produced with 8-10% of fat and approximately 15% of sugar. Lowering the level of fat has until now caused decreased eating quality expressed as less creaminess, body and smoothness. Today's consumers do not accept this. For healthier alternatives to become successful, the eating quality should be at least at same level as standard products. Creamy yet low fat Fat reduct ion in ice cream has traditionally influenced the sensory qualities of the product negatively. A creamy and smooth sensation has been difficult to maintain, and the melting of the ice cream would appear faster than for a similar product with standard fat content. Creaminess is determined by a complex interaction between the raw materials, the composition of the recipe, and the production process. Creaminess is mainly defined by the distribution of air bubbles in the end product - a phenomenon in which emulsifiers, in particular, play an important role. Traditionally, a certain fat content has been required in order to create a fat globule network surrounding and stabilising the air cells. To allow for significant fat reductions in ice cream, Palsgaard has developed an emulsifier system that adds an extremely smooth and creamy sensation to ice cream and allows for significant fat reductions without compromising on neither the sensory characteristics nor the melting profiles and heat shock stability.

ONE can hardly open a newspaper without coming across stories describing the global epidemic - obesity. Sugar and fat - together with over consumption, are often mentioned as the two most important factors causing overweight and the intake hereof should be controlled. Together with cakes and confectionary products, ice cream is included in the food category of which nutritionists recommend a decreased intake. Ice cream is traditionally produced with 8-10% of fat and approximately 15% of sugar. Lowering the level of fat has until now caused decreased eating quality expressed as less creaminess, body and smoothness. Today's consumers do not accept this. For healthier alternatives to become successful, the eating quality should be at least at same level as standard products. Creamy yet low fat Fat reduct ion in ice cream has traditionally influenced the sensory qualities of the product negatively. A creamy and smooth sensation has been difficult to maintain, and the melting of the ice cream would appear faster than for a similar product with standard fat content. Creaminess is determined by a complex interaction between the raw materials, the composition of the recipe, and the production process. Creaminess is mainly defined by the distribution of air bubbles in the end product - a phenomenon in which emulsifiers, in particular, play an important role. Traditionally, a certain fat content has been required in order to create a fat globule network surrounding and stabilising the air cells. To allow for significant fat reductions in ice cream, Palsgaard has developed an emulsifier system that adds an extremely smooth and creamy sensation to ice cream and allows for significant fat reductions without compromising on neither the sensory characteristics nor the melting profiles and heat shock stability.  The solution, Palsgaard IceTriple®systems (patent pending), are fully integrated emulsifier-stabiliser compounds based on propylene glycol esters of fatty acids (PGMS) E 477, and mono-diglycerides E 471, combined with various hydrocolloids, in accordance with local and individual requirements. This breakthrough in ice cream technology is also available in trans fat free versions. Figures 1 and 2 provide a graphic illustration of the sensory profile. Alternative solutions? The latest generation of ice cream freezers makes it possible to extrude at very low temperatures. This has improved the churning and consequently the creaminess and smoothness of the final product, as well as positively influenced the melting resistance. However, although the initial size of the ice crystals is relatively small compared to traditional freezing techniques, ice crystals will still grow during storage time. There is no evidence that heat shock stability is improved through low-temperature freezing, which makes this technique less appealing. Another means of improving the heat shock stability is the use of anti-freeze proteins. However, anti-freeze proteins are not easily obtainable and certain legal issues regarding their application must be observed. Conventional emulsifiers and stabilisers have been applied in ice cream production for many years. They are important in terms of fine-tuning the sensory profile of the product, and also retard the growth of ice crystals. However, they cannot endure repeated temperature fluctuations. Excellent heat shock stability The IceTriple system offers excellent heat shock stability for ice cream. This ensures a pleasant texture and mouth feel even after repeated exposure to fluctuating temperatures. In most parts of the world, ice cream is exposed to fluctuating temperatures before consumption, which in most cases will damage its texture, mouth feel and appearance. The risk of damage to the ice cream is enhanced when the recipe is reduced inNike Hyperdunk 2018

The solution, Palsgaard IceTriple®systems (patent pending), are fully integrated emulsifier-stabiliser compounds based on propylene glycol esters of fatty acids (PGMS) E 477, and mono-diglycerides E 471, combined with various hydrocolloids, in accordance with local and individual requirements. This breakthrough in ice cream technology is also available in trans fat free versions. Figures 1 and 2 provide a graphic illustration of the sensory profile. Alternative solutions? The latest generation of ice cream freezers makes it possible to extrude at very low temperatures. This has improved the churning and consequently the creaminess and smoothness of the final product, as well as positively influenced the melting resistance. However, although the initial size of the ice crystals is relatively small compared to traditional freezing techniques, ice crystals will still grow during storage time. There is no evidence that heat shock stability is improved through low-temperature freezing, which makes this technique less appealing. Another means of improving the heat shock stability is the use of anti-freeze proteins. However, anti-freeze proteins are not easily obtainable and certain legal issues regarding their application must be observed. Conventional emulsifiers and stabilisers have been applied in ice cream production for many years. They are important in terms of fine-tuning the sensory profile of the product, and also retard the growth of ice crystals. However, they cannot endure repeated temperature fluctuations. Excellent heat shock stability The IceTriple system offers excellent heat shock stability for ice cream. This ensures a pleasant texture and mouth feel even after repeated exposure to fluctuating temperatures. In most parts of the world, ice cream is exposed to fluctuating temperatures before consumption, which in most cases will damage its texture, mouth feel and appearance. The risk of damage to the ice cream is enhanced when the recipe is reduced inNike Hyperdunk 2018

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login