One of the world’s largest dairy companies, FrieslandCampina produces and sells consumer dairy-based drinks, infant nutrition, and cheese in Europe, Asia and Africa. The company has a branch in Thailand that can handle 300 million tons of milk per year. The Foremost product range, popular in Thailand, stands out as the best-selling group of references. To handle Foremost PEHD bottles which have a complex shape, the Thailand-based dairy required a high-speed secondary packaging solution in its facility in Samrong. The material handling solution came from Gebo Cermex.

The Foremost portfolio includes yoghurt drinks, condensed milk, UHT milk, pasteurized milk, soy drink and milk powder.

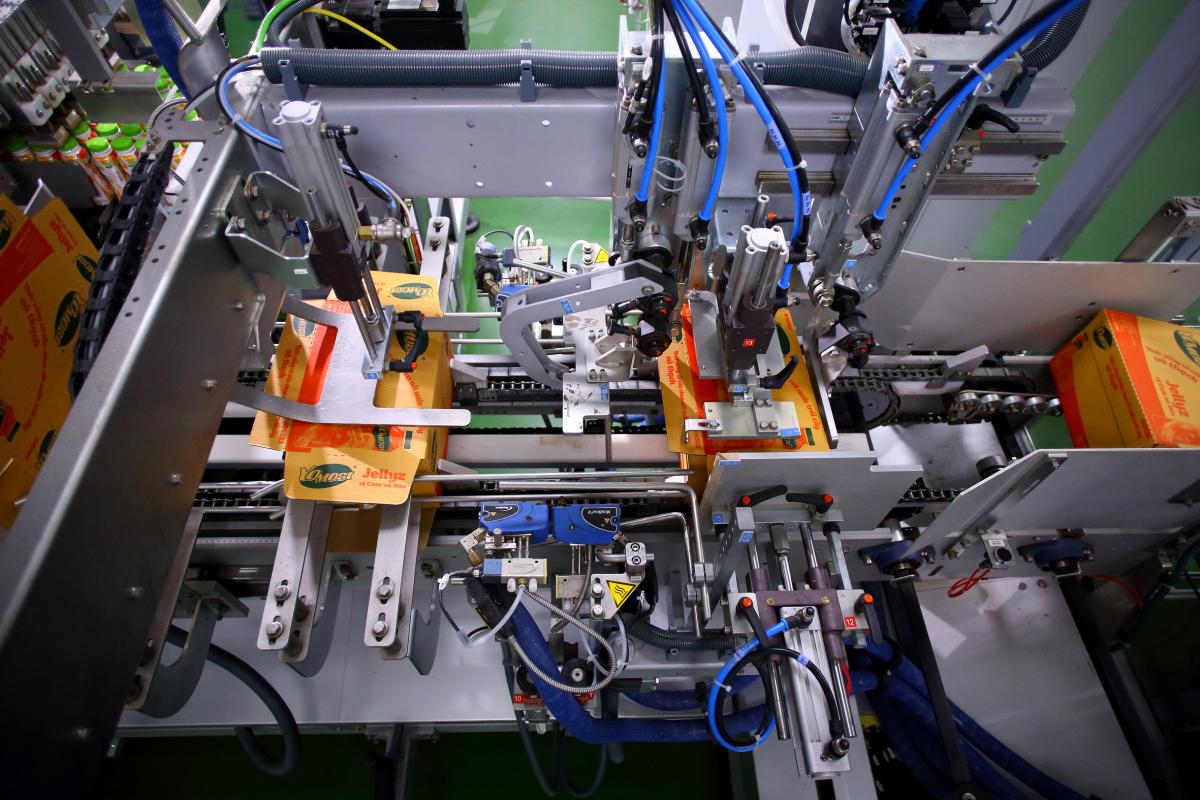

Choosing wrap-around blanks rather than traditional “Regular Slotted Containers” (RSC), the dairy company was able to reduce secondary packaging costs by more than 30%. To achieve this, it opted for a wrap-around case packer machine, together with a bottle line divider at packer infeed – flexible enough to divide the flow from one lane up to eight lanes, depending on the bottle format – and the conveyors connecting the solution to the production line – both upstream and downstream. This configuration ensures an impressive speed of more than 500+ shaped bottles per minute, equal to 24 cases per minute.

Installed at FrieslandCampina Thailand, a wrap-around case packer machine, together with a bottle line divider at packer infeed – flexible enough to divide the flow from one lane up to eight lanes, depending on the bottle format. Conveyors connect the solution to the production line upstream and downstream. This configuration up the speed of more than 500+ shaped bottles per minute, equal to 24 cases per minute. (All images are courtesy of Gebo Cermex)

The partnership between Gebo Cermex and FrieslandCampina Thailand goes back 10 years when the dairy company had a wrap-around packer installed as part of a can line, which is still in operation today.

When the team at FrieslandCampina’s plant explained why they chose Gebo Cermex as their preferred supplier, they address the highly structured and professional support received in all stages of the purchasing and installation process: “They helped us in validating different formats in-house first, so that we could guarantee that by the time we received the equipment in our production facility in Samrong we just ‘Plug & Play’ and then we can get the result we wanted. It’s like a vertical start-up. We chose Gebo Cermex because it is the only manufacturer that can deliver the expected performance within a week.”

Continuous innovation

The latest addition to the Gebo Cermex portfolio of wrap-around solutions is the WB46. It offers excellent performance in terms of flexibility, hygiene and ergonomics, suiting the needs of manufacturers active in a broad range of industries, from food and beverage to pharmaceuticals and home and personal care.

Nike Shox Avenue 802