The building and construction sector is one of the fastest growing markets for high performance flame retardants given the demand for enhanced protection, durability and consistent performance. It is no surprise that leading producers of engineering plastics have embarked on R&D projects to develop compounds that meet the varying needs for flame-retardant materials.

FRX Polymers, Inc. (FRX), a leading manufacturer of polymeric halogen-free flame retardant solutions, highlighted its successful application development work in key markets such as electronics, textiles, building and construction, and transportation. The company has developed a game-changing product line of polymeric and reactive additives to address the global need for non-halogen flame retardant plastics.

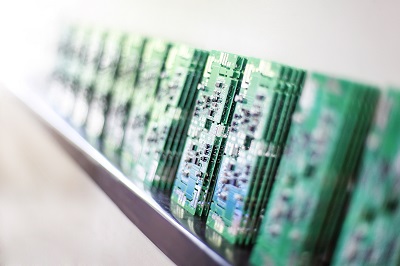

After extensive product development work and the opening of a full-scale commercial manufacturing facility in Antwerp, Belgium, FRX has expanded its global footprint for Nofia FRs and embarked on an ambitious application development effort. The latest commercial applications demonstrate the value-added benefits of the company’s Nofia FRs.

The Nofia system delivers outstanding FR properties, peel strength, and durability. Nofia reactive oligomers achieve this performance because they are used as hardeners and are therefore reacted into the epoxy during the curing process. In addition, they demonstrate good affinity for inorganic additives.

Nofia provides higher level of flame retardance properties for building and construction.

Nofia is being used as the FR additive of choice in PET foam for structural panels used in mass transportation and building and construction markets. Nofia does not disrupt the foaming process and can be successfully applied to virgin and recycled PET. In particular, Nofia oligomers are being used in unsaturated polyester applications in building and construction and transportation. These oligomers deliver numerous benefits over competing non-halogenated FR additives which have limited use due to the plasticizing effect on the thermoset system which affects surface hardness and curing. Nofia oligomers are being successfully formulated in both transparent and opaque applications where aesthetics and weight reduction are key performance requirements.

Nofia phosphonates, FRX Polymers’ polymeric halogen-free flame retardant solution, replace halogenated flame retardants, which are being phased out due to toxicity concerns. Nofia phosphonates are produced using sustainable green chemistry principles such as a solvent-free production process, no waste by-products, and near 100% atom efficiency. FRX Polymers’ portfolio includes an extensive and growing patent estate.

Specialty materials meeting stringent demands

A series of new product developments by another company, KRAIBURG TPE, served as highlights to its exhibit at K 2016. The company introduced flame retardant compounds of the FR/AD1 series; the thermoplastic elastomers of the THERMOLAST® K portfolio were developed especially for applications in the construction industry where they are used to ensure flexible cable installation in flush-mounting boxes. The material is flame retardant in accordance with UL94 and is included in flammability class V0. In addition, it features excellent adhesion with ABS and PC in 2-component injection molding. The flame retardant compounds are highly elastic and are free of latex, PVC and halogen.

Tolsa Group, another supplier of flame retardants synergists specialized additives for the wire and cable, construction or electronics industries, introduced a new range of high-performance FR synergists. The ADINS® Clay extended range are FR clay synergists that deliver reduced smoke production in PVC and rubber polymer systems, in addition to the existing FR additives used in other polymers.

The latest ADINS grades are still based on a breakthrough technology using natural silicates, offering tailored performance benefits, improved processability, and reduced cost in polymer systems. These new materials help meet the new stringent demands for smoke performance (CPR and others) due to the use of more stable coatings than competitive clays. Tolsa has shown that the combination with halogen and non-halogen FR and ADINS® additives in PVC and rubber systems significantly reduces heat release and smoke generation in transportation, electrical/electronics, building and construction, and structural applications.

“This is an important development that broadens the field of applications for ADINS FR synergists,” said Dr. Esteban, technical specialist for Tolsa. “Our ultimate effort is increase the use of clay synergists in a wide range of systems that require the highest standards of flame retardancy.”

Tolsa’s flexible technology facilitates modification of the sepiolite clay to meet the OEM’s strict requirements in terms of heat and smoke performance. In PVC applications, for example, the clay can be modified to attain good dispersion and interaction with the polymer, according to Dr. Esteban.

“Each application is different so our ability to adapt and modify the product is an important advantage in meeting the FR requirements,” said Dr. Esteban.

Key applications include railway and transportation seating and flooring as well as structural parts, and low, medium and high-voltage cables. Available in Europe, the U.S., and other countries worldwide, ADINS® additives are sold as a powder or can be supplied in other physical formats.

Tolsa’s wide range of high-performance flame retardant (FR) synergists are also used in other polymer matrices including PP, PE, PA, and EVA/PE. The company is also focused on translating its unique technology to other key application areas. New ADINS® grades are being developed and undergoing validation in the areas of active packaging, controlling permeability/head space, and biocides.