Impact of mechanical treatment of ice cream at extremely low temperature

Impact of mechanical treatment of ice cream at extremely low temperatureICE cream is a complex multiphase system consisting of ice crystals, air cells, protein and fat globules embedded in a frozen high viscous and concentrated matrix. The microstructure of these constituents has significant impact on the consumer quality characteristics. The process for conventionally frozen and hardened ice cream is: 1.Mixing 2.Pasteurisation 3.Homogenisation 4.Cooling to below 5°C and then ageing 5.Freezing to -5°C and incorporation of air 6.Filling or packing 7.Hardening to -18°C 8.Storage and distribution at -30°C

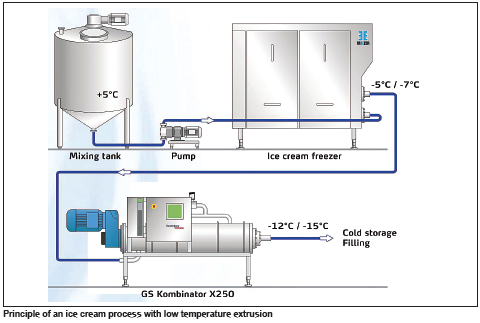

One of the most important steps in ice cream production is the freezing step where the ice cream mix changes from a liquid oil-in-water emulsion to a frozen state. Many of the emulsion drops are destroyed and the fat agglomerates. Air is incorporated and dispersed in the ice cream (up to 50 per cent of the ice cream is air). If the water and ice crystals are not bound efficiently by agglomerated fat, large ice crystals will be formed and the quality of the ice cream will decrease during temperature fluctuations. Effect of further cooling The quality of ice cream can be significantly improved by implementing further cooling after the freezing step. Low temperature extrusion (LTE) is used for this process, where the ice cream is cooled down further from -5°C to -15°C by using ice extruder technology, the Kombinator X250, from Gerstenberg Schröder. The mechanical treatment at very low temperatures in this LTE system has a large impact on the microstructure and characteristics of the ice cream resulting in improved quality. The addition of shear and prolonged treatment during this low temperature extrusion process further minimises the cell size by a factor 2-3, and the size of the ice crystals is reduced by factor 1.5. Additionally, an increased amount of fat globule aggregates is generated in the size ranging from 2 to 20μm, which results in improved melting resistance, improved shape retention and reduced serum drainage. Improvement in ice cream characteristics Scoopability is improved due to smaller ice crystals, which determines the rigidity and scoopability of ice cream at low temperatures. A higher level of 'mouthfeel creaminess' in the melted state at temperatures above 0°C corresponds to a smaller air cell size of the LTE ice cream. High shear forces are also able to form an optimised network of agglomerated fat globules, which further stabilises the ice cream foam. This change in the microstructure make it possible to produce ice cream with lower fat content yet exhibiting similar creaminess as products with higher fat content. The quality of the ice cream can be evaluated by melt down tests, which will show how the fat has crystallise and agglomerated. If the ice cream consists of a higher ratio of fat globules below 20 micron, the melted ice cream will maintain its shape for a longer time. Customer tests have confirmed that ice cream produced by low temperature extrusion using Kombinator X250 show improved quality characteristics. The low temperature extrusion technology results in the following benefits:

One of the most important steps in ice cream production is the freezing step where the ice cream mix changes from a liquid oil-in-water emulsion to a frozen state. Many of the emulsion drops are destroyed and the fat agglomerates. Air is incorporated and dispersed in the ice cream (up to 50 per cent of the ice cream is air). If the water and ice crystals are not bound efficiently by agglomerated fat, large ice crystals will be formed and the quality of the ice cream will decrease during temperature fluctuations. Effect of further cooling The quality of ice cream can be significantly improved by implementing further cooling after the freezing step. Low temperature extrusion (LTE) is used for this process, where the ice cream is cooled down further from -5°C to -15°C by using ice extruder technology, the Kombinator X250, from Gerstenberg Schröder. The mechanical treatment at very low temperatures in this LTE system has a large impact on the microstructure and characteristics of the ice cream resulting in improved quality. The addition of shear and prolonged treatment during this low temperature extrusion process further minimises the cell size by a factor 2-3, and the size of the ice crystals is reduced by factor 1.5. Additionally, an increased amount of fat globule aggregates is generated in the size ranging from 2 to 20μm, which results in improved melting resistance, improved shape retention and reduced serum drainage. Improvement in ice cream characteristics Scoopability is improved due to smaller ice crystals, which determines the rigidity and scoopability of ice cream at low temperatures. A higher level of 'mouthfeel creaminess' in the melted state at temperatures above 0°C corresponds to a smaller air cell size of the LTE ice cream. High shear forces are also able to form an optimised network of agglomerated fat globules, which further stabilises the ice cream foam. This change in the microstructure make it possible to produce ice cream with lower fat content yet exhibiting similar creaminess as products with higher fat content. The quality of the ice cream can be evaluated by melt down tests, which will show how the fat has crystallise and agglomerated. If the ice cream consists of a higher ratio of fat globules below 20 micron, the melted ice cream will maintain its shape for a longer time. Customer tests have confirmed that ice cream produced by low temperature extrusion using Kombinator X250 show improved quality characteristics. The low temperature extrusion technology results in the following benefits:  Creamier, less icy product Optimised reduced fat products due to improved creaminess Shorter and smaller hardening facilities Energy savings Longer shelf life due to smaller crystals In conclusion, the change in the disperse microstructure of low temperature extrusion processed ice cream has a positive impact of the ice cream quality characteristics, such as scoopability and creaminess when compared to those in conventionally frozen and hardened ice cream.(the end)NIKE

Creamier, less icy product Optimised reduced fat products due to improved creaminess Shorter and smaller hardening facilities Energy savings Longer shelf life due to smaller crystals In conclusion, the change in the disperse microstructure of low temperature extrusion processed ice cream has a positive impact of the ice cream quality characteristics, such as scoopability and creaminess when compared to those in conventionally frozen and hardened ice cream.(the end)NIKE

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login