THE FOOD & BEVERAGE Industry in Southeast Asia is becoming ever more robust, and consequently speeding up the race for automation.

Warehouse automation specialist, Consoveyo Singapore (Consoveyo) notes the strong growth channels that are coming from three fronts: track and trace, cold store warehouses, as well as food online shopping.

Requirements for automation have grown remarkably in Asia, according to Consoveyo’s head of marketing & sales, Louis Kok. “Firstly, there is a strong requirement for track and trace or traceability as a direct result of demand for food safety.”

Traceability requires information covering delivery and shipping activities, and sources and expiration dates on ingredients and finished food products. The latest track and trace technologies enable suppliers and manufacturers to protect their products as these move within the supply chain.

As for food safety, a recent World Health Organisation report has estimated 600 million – almost 1 in 10 people in the world – fall ill after consuming contaminated food and 42, 000 die every year, resulting in the loss of 33 million healthy life years (DALYs). Children under 5 years of age carry 40% of the foodborne disease burden, with 125,000 deaths every year.

Mr. Kok adds that growing demand for freezer storage or cold store warehouses is also fueling the growth of automation especially in Asia.

Louis Kok, Consoveyo’s head of marketing & sales

Science Direct reports that on an environmental level, “changing climate, rainfall and temperature are challenges to food traceability”. With food supply chains increasingly crossing multiple national borders, and with traceability remaining important for both importing and exporting countries, concern for food safety and freezer storage is expected to continue.

“Online food shopping is also another channel that’s growing tremendously now.” No surprises there as online food delivery and online shopping platforms are increasing the number of choices and convenience to customers across the region and the world. But Mr. Kok says, “Customers are expecting increasingly shorter delivery time. This results in a lot of stress on retailers and back-end warehouses to push out their order to meet a higher service level. So, really, using automation would be a good start to mitigating all these challenges.”

Automation for SMEs

Southeast Asia is showing stronger interest in automation as this becomes the roadmap to increased productivity. Thailand for one has been very aggressive in the adoption of industrial robotics and automation in manufacturing.

Elsewhere in the region, smaller companies would think twice in investing in automation. Many manufacturers are conservative when it comes to such investments. But Mr. Kok points out that this should not be the case. “Smaller- and medium-sized companies would have a stronger reason to automate. Automated processes decrease inefficiency and improves productivity for warehousing operations. In fact, automation is especially helpful if SMEs want to expand their business, but don’t have the land to do so. It’s often challenging for them to obtain leases for land from their respective governments. In order to be able to continue their business and to cope with their growth, SMEs need to invest in automated warehouses, which allows for increased storage within a smaller footprint.”

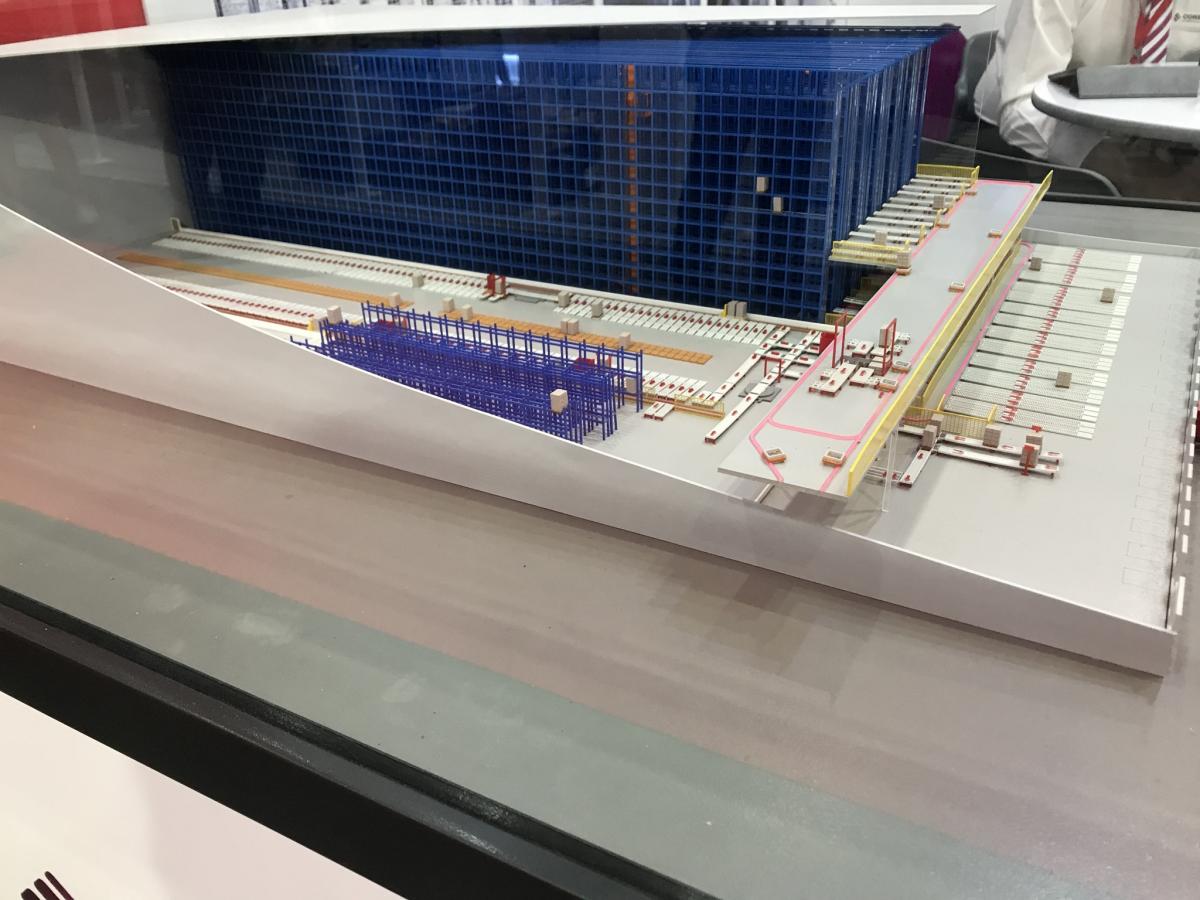

Like any other space requirements in Asia, manufacturing and storage spaces are expanding vertically in the region. By utilising vertical space within a warehouse, Consoveyo’s ASRS solution is capable of handling and processing high volumes of orders in a given period of time and space.

Scale model of an Automated Storage and Retrieval System by Consoveyo

Consoveyo, with its full suite of automated storage and picking solutions, says food and beverage is among its top three businesses.

In Indonesia, Consoveyo has implemented for PT Smart an Automated Storage and Retrieval System (ASRS), which is intended to help manufacturers maximise storage space, reduce labour cost, and ensure workplace safety and warehouse security. PT Smart cultivates and harvests oil palm, processes fresh fruit bunches (FFBs) into crude palm oil (CPO) and palm kernel, and refines CPO into value-added products such as cooking oil, margarine, shortening, specialty fat, biodiesel, as well as palm products throughout the world. It operates 16 mills, five kernel crushing plants and four refineries across Indonesia. Back in 2012, Consoveyo also installed another ASRS for a leading dairy production company in Indonesia.

In Singapore where Consoveyo’s Asian headquarters is located, the company recently completed an automated warehouse for a multi-tenant food building for a local government organisation.

Positioning for growth

Anticipating increased growth in the food and beverage industry and in the region, Consoveyo is investing in making its team more responsive and better able to support its customers.

“We are definitely looking to further enhance our capabilities in this region. We are committed to assembling an exceptional team, so we are better able to service and support our customers in this region in the coming years.”

Aside from its automated solutions, Consoveyo provide enhancement and retrofitting services for older ASRS systems. In addition, Consoveyo extends after-sales, project management, sales and marketing, and programming support to its customers.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login