Introduction

THE FAST-CHANGING environment and framework conditions of the food industry require that companies keep pace with developments like those related to changing consumer behaviour and market saturation (Weindlmaier, 2001). As such, the opportunity to expand market share largely depends on the ability to successfully introduce new and unique products (innovation) in the market at a rate faster than competitors. Therefore, companies will win competitiveness if they are: (a) able to increase the number of innovations of highly acceptable products in the marketplace; and (b) capable of continuously improving the effectiveness of their innovation process (Cooper 1994). In this regard, it is of great importance that innovation activities be so organized as to ensure sustainable competitiveness enhancement through time.

Description of competitiveness

When the identified needs of the customers become the basis for new product or process development, assurance of consumer positive response to the new product or process can be expected. Increased customer demand promotes leadership in the marketplace with ultimate enhancement of competitiveness. This assumes that the company leadership fully support innovation activities such that they keep updated with information and knowledge about their target markets and consumer behaviour. The speed with which new and unique products (innovation) are launched in the market with positive consumer response greater than that of competitors determines, to a large extent, its level of competitiveness. When quality, productivity and profitability go hand-in-hand with the speed of innovation and a sustainable customer positive response is obtained, the company’s performance would most likely be better than the competitors. Although difficult to measure, competitiveness is almost always associated with profitability trends being higher than the closest rival and sustained through time.

Overcoming competitors

It is not easy to identify who are the competitors, but it is important that a benchmark performer should be identified as early as possible to serve as a comparative performance target. There are three major contributions that organized innovation activities can provide to enhance competitiveness: (1) shortened time to market; (2) lowering expenses by resolving most costly problems; and (3) inventing future products and processes ahead of competitors

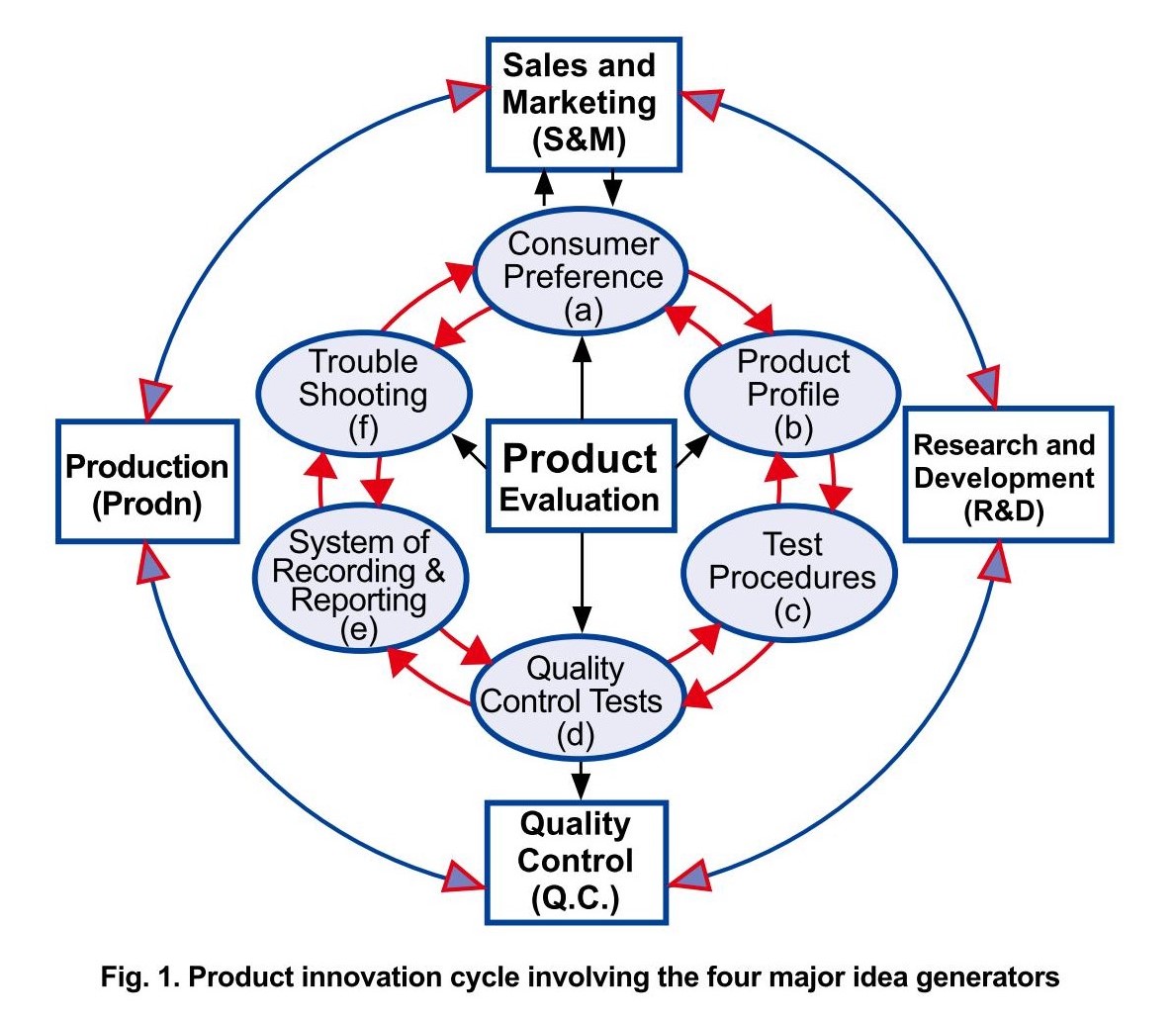

Shorten time to market. Figure 1 shows a development cycle in the organization of innovation activities, which facilitates output completion and thus shortens time to market of the new product. The four major idea generators in the Company include: Sales and Marketing (S & M), Research and Development (R&D), Quality Control (Q.C.) and Production (Gatchalian and Brannan, 2011). Their individual contributions, when properly synchronised, lead to product or process innovation. A highly competitive company would first make sure that their S&M Team will always take the opportunity to: (a) regularly meet and understand their customers; (b) know the consumers’ current and future requirements; and (c) be adequately guided in their recommendations to R & D. The two-pronged arrowheads between S&M and R&D implies constant sharing of ideas especially those pertaining to product and process improvements, as well as, to new product ideas for development. The speed with which these new ideas are approved by management, the earlier would the innovation process be initiated, processed and then completed. As such, speed of communications between R&D, Q.C. and Production shortens new product and process standardisation towards eventual properly planned product launching.

Lowering expenses by resolving most costly problems. Customer complaints spells “trouble” to the food processor and the faster this is resolved, the easier it is to regain customer confidence and consequent retention. Figure 1 shows that S & M is directly in contact with the customers and normally receives first the good and/or bad feedback from them. The innermost counterclockwise arrowhead from Customer, points to “trouble” and especially if this pertains to the newly marketed product, immediate action is required. A good starting point is to review the records kept by all concerned so that a fast resolution is achieved and provided to the complainant. Losing a good customer is a costly problem requiring quick action and this is why the innovation cycle provides the avenue for fast response through a properly planned records review and subsequent corrective action.

Inventing future products and processes ahead of competitors. The two inner circles with arrowheads in clockwise (outer circle) and counter clockwise directions in Figure 1 briefly describes the activities undertaken during the innovation process. Note that the emphasis (clockwise arrows) is first focused on understanding consumer preferences or acceptability, using sensory evaluation approaches through consumer-type survey (Gatchalian and Brannan, 2011). Once customer preference for a specific product is established, a product profile using Quantitative Descriptive Analysis (QDA) is done to establish critical characteristics. Based on QDA findings, the product design is finalised and quality test procedures are developed to define process and product specifications. Should the product fail to meet customer requirements (“trouble”), reverse arrows point to review of records which should facilitate corrective action and prevention of recurrence. Thus, speedy actions related to product development, quality assurance and customer feedback are immediately done. This well- planned and organised innovative cyclic approach serves as the framework for a speedy, new and unique product development to remain ahead of the competitors.

Enhancing competitiveness

Although complete association between competitiveness and innovation is not yet fully established, still it is logical to believe that the faster the innovation of highly acceptable unique products, the higher the opportunity to lead in the marketplace (Gatchalian, 2017). This is especially so, if the speed of successful innovation is faster than that of the competitors. As discussed earlier, properly organised innovation processes will result in: (a) reduced time to market; (b) lowering expenses through fast costly problem-resolution; and (c) introducing new products and processes ahead of competitors. These major contributions of organised innovation activities coupled with adequate control of product quality and productivity redound to the company’s increased profitability through time which is predictably faster than the competitors. Also, expectedly, there could be short periods of time when the company may even have a monopoly in the marketplace of such developed new and unique products and processes. More importantly, when innovation activities have become systematic and measurable, increase in profitability through time is observable as a rising trend. All these could have direct impact on the company’s bottom line, perhaps comparatively better than the closest competitor. With sustained speed in successful innovations, the ultimate result would be enhancement of competitiveness.

Innovation activities

Innovation is a unique creative idea that adds value to the organisation’s external customers and to the stakeholders while generating profit (Gatchalian, 2018). It is also a form of problem-solving process (Galizzi G. and Venturini, 1996) that requires use of tested tools and techniques to avoid waste of time, money and effort. Therefore, first and foremost, Management must be fully committed to engage in innovation, thus giving support to companywide involvement in the activity. Under this favourable environment, the innovation process can best be initiated.

Nature and type of food innovation. By its very nature, the food industry is known to have low R&D intensity (Menard, 2007) and in most cases for new products launched, more than 75% fail to be sustained in the marketplace. Traditionally, it is known that those in the food business use incremental innovation or the “me too product ” type, knowing from experience, that the success rate of a new product in the market, is only for a short period. Thus, to sustain the capability to continue making a “new product” the food company apply variations on existing ones, done mainly to respond to constantly changing customer expectations. Radical innovation on the other hand requires high cost of R&D work since it takes a much longer time to generate entirely new concepts and then complete the innovation process. Consumers of food products seek variety and novelty on the food they eat and physical changes or improvements that virtually show uniqueness compared to past experience, obtain higher level of acceptability. For this consideration, the “me too products” that show uniqueness gain faster acceptance to the customers known to be readily impressed with new and unique products. Furthermore, the new entry could cause a temporary monopoly in the market, giving an advantage to the creator company. Therefore, a well-planned and organised incremental innovation process could enhance competitiveness in the food industry.

Major activities for innovation. After Management announces full support for innovation activities, the first step is to develop sustainable approaches to continually understand targeted consumer needs. This is followed by proper utilisation of company resources to generate product or process ideas then have them systematically screened using problem-solving tools to identify the most important consumer needs at a given point of time. Towards this end, it is important to select the type of innovation that will most likely produce results that will establish the company’s position in the marketplace. For the food industry, the incremental type of innovation would include major activities such as: (1) securing management commitment to engage in innovation activities; (2) understanding, identifying and measuring customer needs; (3) brainstorming on ideas generated leading to systematic screening; (4) product and process designing and testing for potential consumer acceptance; (5) commercialisation of production and launching in the market; and (6) monitoring market level of acceptability and preferences through time. All these activities will need to be well-planned and organised into the innovation process to assure long-term successes that concretely enhance competitiveness. Innovations are an important instrument for companies in the food industry to stand out from competitors and to fulfil consumer expectations (Menrad, 2004).

Organisation of food innovation activities

An organised innovation implies, a good knowledge of the intended customer’s requirements and needs. Hence, it is imperative that the capability to identify, measure and respond to customer needs become major activities of a well-planned, developed and constantly improved innovation process. As such, the great challenge in product development is to be able to identify the item that is most acceptable to the target consumers.

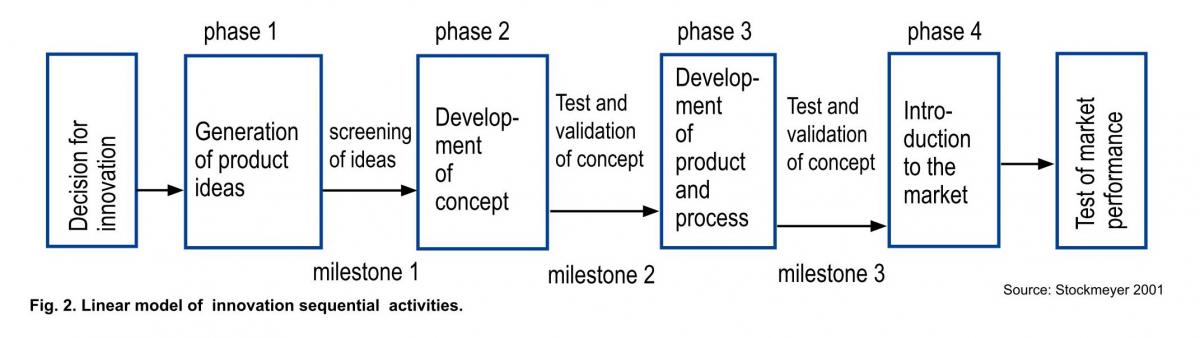

The innovation development cycle shown in Figure 1 above, presents the cyclic activities employed in a food company to initiate and then sustain product and quality development activities through a never-ending series of activities (cyclic). Initial plans for this never-ending cycle utilize a linear model to innovation which considers the activities from the time of conception of new ideas (Phase 1) to the time it is introduced into the market (Phase 4) and subsequently competing with other players. Figure 2 presents the Phases of innovation as a linear and sequential approach which starts with Phase 1- Generation of ideas; Phase 2 – Development of concept; Phase 3 -Development of product and process; and Phase 4 – Introduction to the market ( Stockmeyer, 2001).

Phase 1 – Generation of ideas. A company that decides to engage in innovation activities must first be fully convinced that it is willing to utilize all company resources to assist in the total process Gatchalian (2018) discussed what are necessary preparations to venture into the innovation processes and it was clearly emphasised that total people involvement is the key to succeed in innovation management. It is the workforce’ active involvement which can make idea generation progress with speed under the leadership of idea generators such as those from S&M and R&D. “Brainstorming” is one of the most useful problem-solving tools for screening of ideas generated and as a first screening step, the “Affinity Diagram” (AD) is often utilised as shown in Figure 3. It simply involves writing one perceived product characteristic on each of the coloured post-it papers until as many as 20 or more perceptions had been collected from every member of the Innovation Team. These are analysed and grouped into major characteristics which then provide some basic understanding of the product perception as contributed by the Team. The summary of the output becomes milestone number 1 in the sequential process.

Figure 3 Affinity Diagram” (AD)

Phase 2 - Development of concept. Product identity derived from Milestone 1 is studied with extensive use of sensory evaluation tools and techniques to better understand the sensory characteristics. If practicable, a sample product may be prepared from which a profile using the QDA approach can be developed (Gatchalian, 2011). These sensory test results generally require their correlation with respective physical and chemical measures for use later in Phase 3 (focused on development of product and process specifications). Results of Phase 2 describes milestone number 2 that presents the product identity.

Phase 3 – Development of product and process. Once the identified product is made clear through measurable characteristics, several formulations of identified ingredients are developed. This is to determine which formulation would best meet the product characteristics desired by customers as determined by the innovation Team. Four or more formulations are studied at the start, until eventually one becomes a final choice for laboratory scale production. At this stage, (a) process specifications are carefully developed to insure reproducibility of product characteristics; (b) sensory evaluation is done at each development stage; (c) a consumer-type survey is conducted to predict consumer preference and acceptability; and (d) physical and chemical measurements are conducted, as required. When positive market potential is seen as a result of the consumer-type survey, pilot scale production is done followed by actual consumer survey to confirm product market acceptability. Results of Phase 3 is considered as milestone 3 with new product and process developed and standardized.

Phase 4 - Introduction to the market. Generally, companies require that the product acceptability score must meet their desired average (i.e. hedonic rating average score = 8.5 or “like moderately +”) before it is launched into the market. Once this is achieved, commercial production is started followed by market launching. During commercial production, the standardized process specifications are employed to achieve the desired product characteristics as defined in the accepted product profile together with physical and chemical measurements.

Conformance to customer expectations. Before the new and unique product is launched into the market, assurance that it would meet customer expectations is first confirmed. Considerable sensory evaluation tests are conducted during the development of several formulations from which one or two are selected for laboratory scale production. The product is subjected to consumer-type survey to measure average acceptability score that determines its potential marketability. At the laboratory scale production stage, product and process specifications are carefully standardised for use in quality control during commercial Production. Before market launch, a full-blown market survey is conducted to reaffirm that the required average consumer acceptability score is achieved.

Test of market performance. The attributes and characteristics of new food products determine the success of innovation to a high extent (Menrad, 2007) and this is why a consumer survey is very important before product launch. Because of the high failure rate of food innovations it is urgent that the food industry take into serious consideration some factors that could also affect the product introduced into the market (Cooper R.G.; Kleinschmidt E.J.1991). Management expect S&M to be updated on results of market researches particularly with regards to price sensitivity and buying behaviour of consumers. Likewise, R&D, Q.C. and Production, guided by information gained about the selected product during its development stages, should utilize various monitoring approaches to assure retention of product quality. This will insure maintenance of customer acceptance level in the marketplace. Constant monitoring of consumer feed-back, usually by interviews or regular measurement of Customer preferences (relative to competitors) and acceptability level is highly recommended so that early detection of decline in customer support can be known and promptly acted upon.

Summary

Competitiveness is basically taking advantage of the opportunity to expand market share by fully harnessing the ability to successfully introduce new and unique products (innovation) in the market at a rate faster than competitors. Therefore enhancement of competitiveness can be a goal to be achieved through organised innovation activities which are sustainable and expected to contribute in increasing profitability through time. The major innovation activities can be organised following the sequential steps of: (1) generation of ideas; (2) development of product concept; (3) development of product and process and (4) introduction into the market. For assurance of product market sustainability it is important that its performance be constantly monitored especially against competitors. Action should immediately be done when change in consumer response start to show signs of a possible decrease in comparative acceptability.

References

Cooper R.G. (1994): New products: The factors that drive success. In: International Marketing Review, Vol. 11, ISS. 1

Cooper R.G.; Kleinschmidt E.J. (1991): The impact of product innovativeness on

performance. In: Journal of product innovation management, Vol. 8, ISS. 4

Galizzi G.; Venturini L. (1996): Product innovation in the food industry: Nature, characteristics and determinants. In: Economics of innovation. The case of the food industry (Eds.): Galizzi G. and Venturini L. (Physica Verlag, Heidelberg

Gatchalian, M.M. 2017. Enhancing competitiveness through innovation leadership. Proceedings, 26th Mexico Asia Pacific Quality Seminar and IMECCA International Forum Cuernavaca , Mexico. October 5, 2017

Gatchalian, M.M. 2018. Innovation management in food product development. Food Pacific Manufacturing Journal. Vol. XVIII, No. 2, March 2018. ISBN 1608-7-100.

Gatchalian, M.M. and Brannan, G.D. 2011. Sensory Quality Measurement: Statistical Analysis of Human Responses. Quality Partners Company. Ltd. Philippines.

ISBN 978-971-691-921-9.

Gatchalian, M.M. and Cruz, M. 2011. Sensory quality measurement: the case of Red Ribbon Bakeshop, Inc. Proceedings. 55th EOQ –Budapest, Hungary, June 21-23 Menrad, K. 2007.

Innovations in traditional food products in small and medium-sized companies of the food industry. Review of literature.

Menrad, K. (2004): Innovations in the food industry in Germany. Research Policy 33, 845-878

Weindlmaier H. (2001): General aspects of food innovation management. In: Food innovation management from idea to success (Eds.): Roland Treillon 2001

Nike Air Max