PACK EXPO Las Vegas is expected to host 30,000 attendees, including 5,000 international visitors from more than 125 countries, combined with 2,000-plus exhibiting companies. The show produced by PMMI, The Association for Packaging and Processing Technologies, takes place at the Las Vegas Convention Center; Sept. 25-27, 2017. It will include the inaugural Healthcare Packaging EXPO, which will be co-located with PACK EXPO.

Here are a few innovations you can expect to see at the show floor:

CleanTech®

Automated hand and footwear washing saves time, cost

Meritech (Booth #N-411, #S-7555) will exhibit CleanTech®, a fully automated handwashing system with an integrated footwear sanitizing pan for pathogen control. CleanTech cleans hands and sanitizes shoes, boots or any footwear in 12 seconds, helping to control contamination risks, improving employee hygiene and saving time and money by allowing employees to return to work faster. Fresh sanitizing chemicals flush through the system with every hand wash cycle, ensuring that pans are constantly maintained at FDA recommended sanitizer levels between 800-1,000 PPM. Meritech products also use 75% less water, require less soap and reduce discharge waste when compared to equivalent manual handwashing.

ACTIVIA programmable paper tube and core re-cutter

Improve accuracy with an automated paper tube re-cutter

PAKEA (Booth #S-5822) introduces the ACTIVIA programmable paper tube and core re-cutter. This automated single-knife index re-cutter facilitates low tooling costs and quick size changeovers leveraging its large diameter range and touch screen graphic interface. ACTIVIA also enables accurate cutting lengths and low energy and operating costs. The solution is available with an optional automatic feed hopper for fully automatic operations.

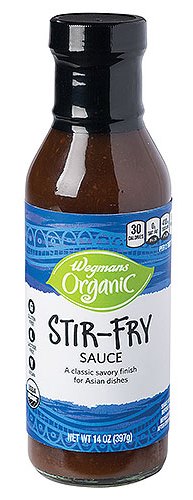

Digimarc Barcode

Invisible barcode offers visual appeal and efficiency

Inland (Booth #S-6535) will showcase a new label with a unique interactive digital watermark called the Digimarc Barcode. Invisible to consumers, the unique barcode is repeated multiple times over the entire label so that it can interact with POS scanners and mobile devices. The barcode delivers data including the same Global Trade Item Number (GTIN) currently carried in traditional produce barcode symbols (UPCs). The Digimarc Barcode frees up space on product packaging for branding and information and increases efficiency in the checkout line.

TOMRA 5A sorter

TOMRA BA sorter

Potato product sorters bring greater productivity and safety

TOMRA Sorting Solutions (Booth #S-8027) announces the launch of two new innovative sorting machines: the TOMRA 5A and the TOMRA 5B. The TOMRA 5A, which sorts whole unpeeled and peeled process potatoes, offers foreign material removal and potato quality sorting controls. The TOMRA 5B sorts vegetables, French fries, chips and other potato products, features smart surround view technology, high-resolution cameras and high-intensity LEDs. Both machines are specifically designed to improve product quality and safety, while providing minimal product waste and maximum uptime.

Easy-open foil lids save customers time and manufacturers money

Bemis Co., Inc. (Booth #N-526) will launch its Calypso™ line of die-cut foil lids for yogurt and other dairy products. Compared to traditional foil lidding that tears in half or does not open completely, Calypso boosts tear strength by more than two times to allow for easy opening in one piece. Calypso is also made with less aluminum materials than other foil lids, cutting carbon dioxide by 35 percent and energy by 10 percent for greater sustainability.

Sleever® Combisteam LDPET

Sleeving machine presents savings and recyclability

Sleever International (Booth #S-5922) will launch Sleever® Combisteam LDPET, a sleeve label applicator that offers significant space and energy savings along with ecological credentials. The machine works at a processing speed of 600-1,200 units per minute and saves 40 percent in floor space and 50-60 percent in energy consumption compared to traditional sleeving machines. As an added advantage, recycling centers can quickly separate the special sleeves from PET bottles, which can then be 100 percent recycled.

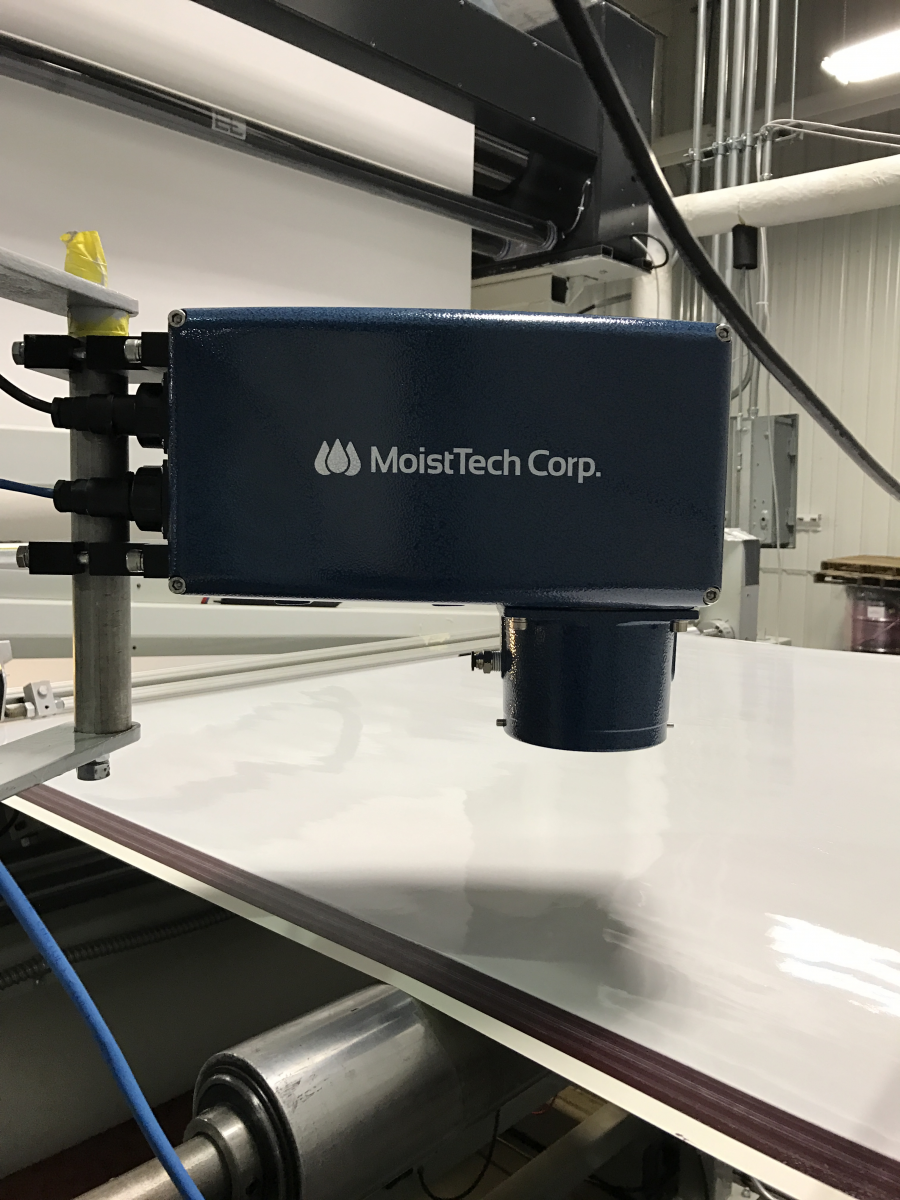

IR3000 Series Sensor

Easy-use sensor provides multi-functionality and accuracy

MoistTech Corp. (Booth #S-7804) presents the IR3000 Series Sensor, which measures moisture, oil and fat content, as well as the thickness and weight of coatings, hot melts, glues, adhesives, printing and more. The sensor’s near infrared (NIR) technology brings high accuracy levels and offers the ability to measure multiple constituents instantly with one unit. It reduces downtime and start-up time, eliminates waste and energy costs, and monitors moisture and other constituent levels at every stage of the process.

Vectra® cartoner from Douglas Machine

Cartoner design maximizes efficiency and flexibility

Douglas Machine, Inc. (Booth #C-2014) will launch its Vectra® cartoner, delivering simplicity and savings with speeds of 300 cartons per minute and a 40 percent floorplan reduction. The Vectra®’s flexible platform offers a 9 inch and 12 inch pitch and a removable carton forming guide to ensure consistent carton picks for quick and predictable changeovers. The cartoner is available in low-, mid- and high-speed applications and an open, tube-free frame design.

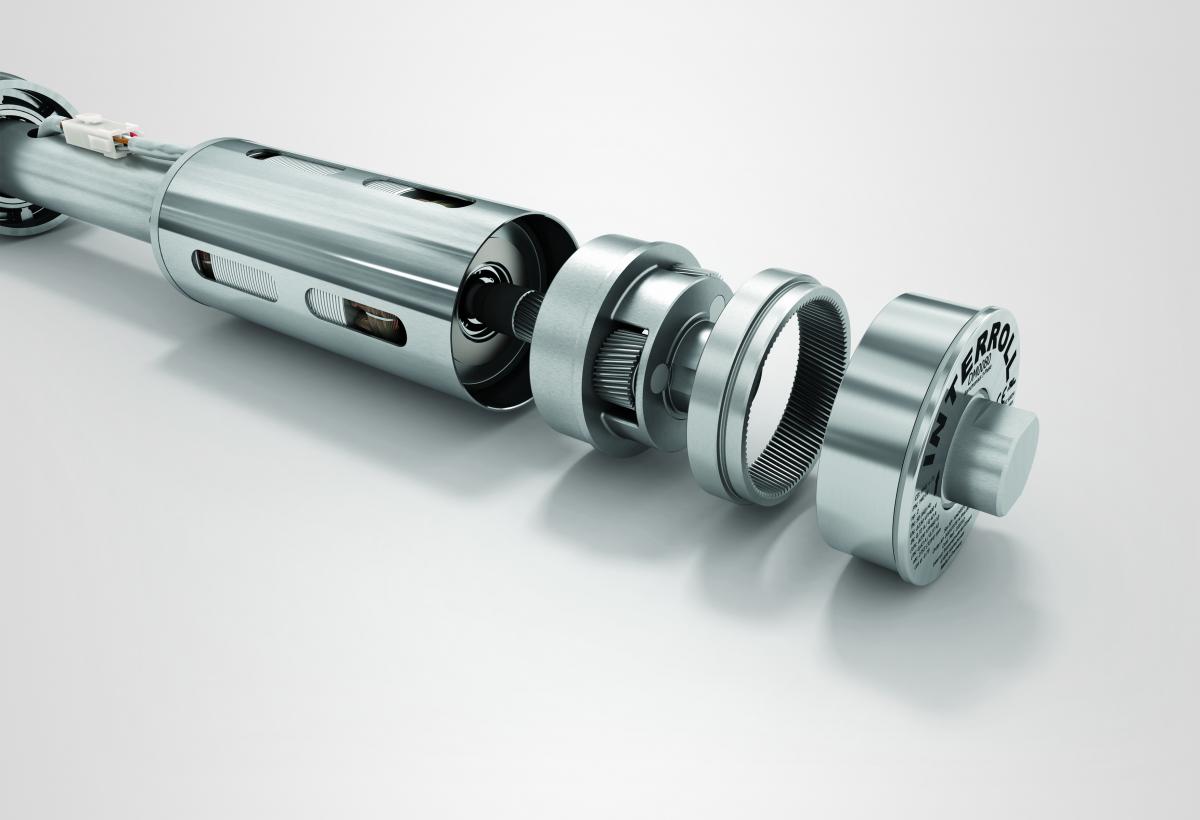

Interroll belt drive

Belt drives extend service life and flexibility

Interroll Corp. (Booth #S-7356) is introducing a new collection of belt drives. The drum motor platform, used with manufacturing conveyer belts, distribution centers and for food applications, starts with a diameter of 80 mm and can be configured to meet specific application requirements while optimizing costs. The belt brings longer service life, greater speed ranges and a simple power supply, reducing downtime for maintenance and repairs.

Ultrasonic generator creates seamless bonds for coffee capsules

Herrmann Ultrasonics, Inc. (Booth #S-5935) will showcase its new, slim ultrasonic generator, ULTRAPACK AMG. The machine’s 48 stations, powered by 24 generators and producing 1,200 watts, weld filter liners onto capsule bottoms for applications in the coffee industry. Ultrasonic machines create a consistent bond when combining packaging materials made of PP or PE with nonwoven materials like filter liners, perforated films or filter papers on coffee capsules.

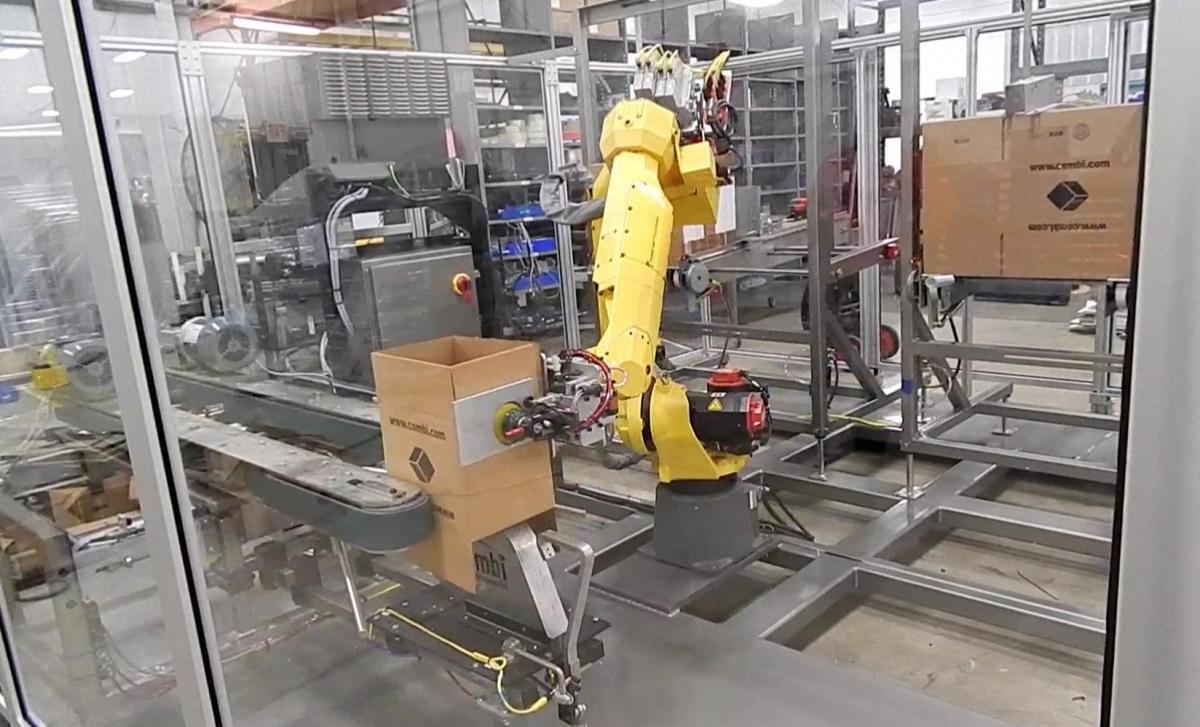

RCE Robotic Random Case Erector end-of-line packaging solution

Robotic technology offers end-of-line packaging solutions

Combi (Booth #C-2228) will introduce the RCE Robotic Random Case Erector, which combines a six-axis robot with multiple case magazines and a bottom flap folder with integrated 3M™ tape head. The FANUC robot has a flexible end-of-arm tool to pick and erect multiple cases, eliminating the need for multiple erectors, reducing floor space and costly changeover downtime.

Lima 320 VFFS packaging machine with Integrated Cornersealer™

Packaging machines bring versatility for a variety of bags

UVA Packaging (Booth #S-5969) will present its Lima 320 VFFS packaging machine with Integrated Cornersealer™. Offering versatility and continuous motion operation, the Lima 320 VFFS machine allows users to produce seven different bag styles on a single machine, including pillow bags, gusseted bags, block bottom bags, block-bottom corner-creased bags, block-bottom corner-seal bags, doy-style pouches and push pop bags. The Integrated Cornersealer allows the Lima 320 to produce block bottom corner-sealed bags that were not possible with previous generations of VFFS machinery.

Specright's automatic supplier scorecard

Automatic supplier scorecard simplifies feedback process

Specright (Booth #S-7859) presents its new automatic supplier scorecard, which eliminates manual data entry by pulling quality, cost, delivery and sustainability data from existing data sources. Not only does the scorecard give suppliers real-time access to feedback, it also enables them to reply and offer additional information regarding non-conformance issues. The metrics gathered by the scorecard help manufacturers determine how their packaging innovations, environmental standards, energy efficiencies and use of materials stack up.

Register for PACK EXPO Las Vegas 2017 at packexpolasvegas.com.

sneakers

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login