Engel Austria GmbH已经开始装备高速系列机器,其采用能够激发速度设置的智能软件模块来运行。该系统引人瞩目之处在于它对滚筒运动的计算具有参考价值:它的自动综合调节系统可以让其运动达到最适宜程度。而且,这种软件很容易操作,普通的机器操作员也能够切实地运用它所具有的一切潜能。

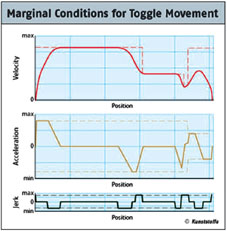

High-performance Injection Molding. Formula 1 racing cars and fast-cycling injection molding machines have one thing in common: tuning them for high speed may require unconventional solutions and new ways of thinking - like the toggle geometry developed for Engel?s Speed-series machines. They feature smooth movements thanks to a virtually constant stroke/velocity ratio and automatic operating point setting. In order to obtain the shortest cycle times possible, the setup technician has to optimize the settings on toggle-type machines in a series of approximations. The hard part is finding a compromise between acceleration and braking phases without causing the machine to vibrate inherently. And he has to do this for each and every operating point, since even the best settings are not universally valid, but always limited to a particular stroke and depend on the weight of the injection mold. Moreover, the setting values vary from one machine to another. It takes an experienced setter, one familiar with fast-cycling applications, to realize top machine performance at each operating point entered. Since not every operation can field such expertise, fast-cycling machines often operate at less than their true capabilities. As its contribution to solving the problem, Engel Austria GmbH has already begun equipping its Speed series machines with the intelligent software module Active Speed Setup. What makes the system so attractive is that it calculates reference values for platen motion: Its integrated regulation system automatically causes movements to approach their calculated optimum. This software is an easy-to-operate aid that enables the average machine operator to actually exploit the entire potential of the machine. Mechanical requirements for the toggle system The project team?s objective was to develop a system for minimizing the dry-cycle time of the toggle clamp unit of an injection molding machine without negatively affecting its running smoothness. To this end, they studied the vibration behavior of the machine frame. Frame vibrations stem from the free mass forces of the moveable platen and are dependent upon the platen?s acceleration, as well as on the toggle?s tendency to jerk and jolt. Each machine thus has its own endemic vibration curve. Since the starting point toward the developmental goal was to calculate an ideal reference movement to minimize permissible characteristic vibration, they naturally focused on the shortest particular mold opening and closing period possible - dependent, in every case, on the platen stroke setting. The machine setting should then be limited to regulation system automatically causes movements to entering the desired opening path and of the hydraulic valves, by the maximum basic data of the injection mold.

As its contribution to solving the problem, Engel Austria GmbH has already begun equipping its Speed series machines with the intelligent software module Active Speed Setup. What makes the system so attractive is that it calculates reference values for platen motion: Its integrated regulation system automatically causes movements to approach their calculated optimum. This software is an easy-to-operate aid that enables the average machine operator to actually exploit the entire potential of the machine. Mechanical requirements for the toggle system The project team?s objective was to develop a system for minimizing the dry-cycle time of the toggle clamp unit of an injection molding machine without negatively affecting its running smoothness. To this end, they studied the vibration behavior of the machine frame. Frame vibrations stem from the free mass forces of the moveable platen and are dependent upon the platen?s acceleration, as well as on the toggle?s tendency to jerk and jolt. Each machine thus has its own endemic vibration curve. Since the starting point toward the developmental goal was to calculate an ideal reference movement to minimize permissible characteristic vibration, they naturally focused on the shortest particular mold opening and closing period possible - dependent, in every case, on the platen stroke setting. The machine setting should then be limited to regulation system automatically causes movements to entering the desired opening path and of the hydraulic valves, by the maximum basic data of the injection mold.  Highsnobiety Style

Highsnobiety Style