A PLATFORM for complete value chains, interpack encompasses processes and machines for the packaging and processing of packaged products and packaging materials, packaging means, and their production, and services. This year, it brings to focus Industry 4.0 which will be presented in cooperation with the German Engineering Federation (VDMA). Now also a vital part of this German trade show is “innovationparc”, a stimulating and must-see segment that exhibits packaging strategies and solutions to reduce food loss and wastage.

Bosch Packaging Technology and Kliklok Corporation

Hall 6, A31

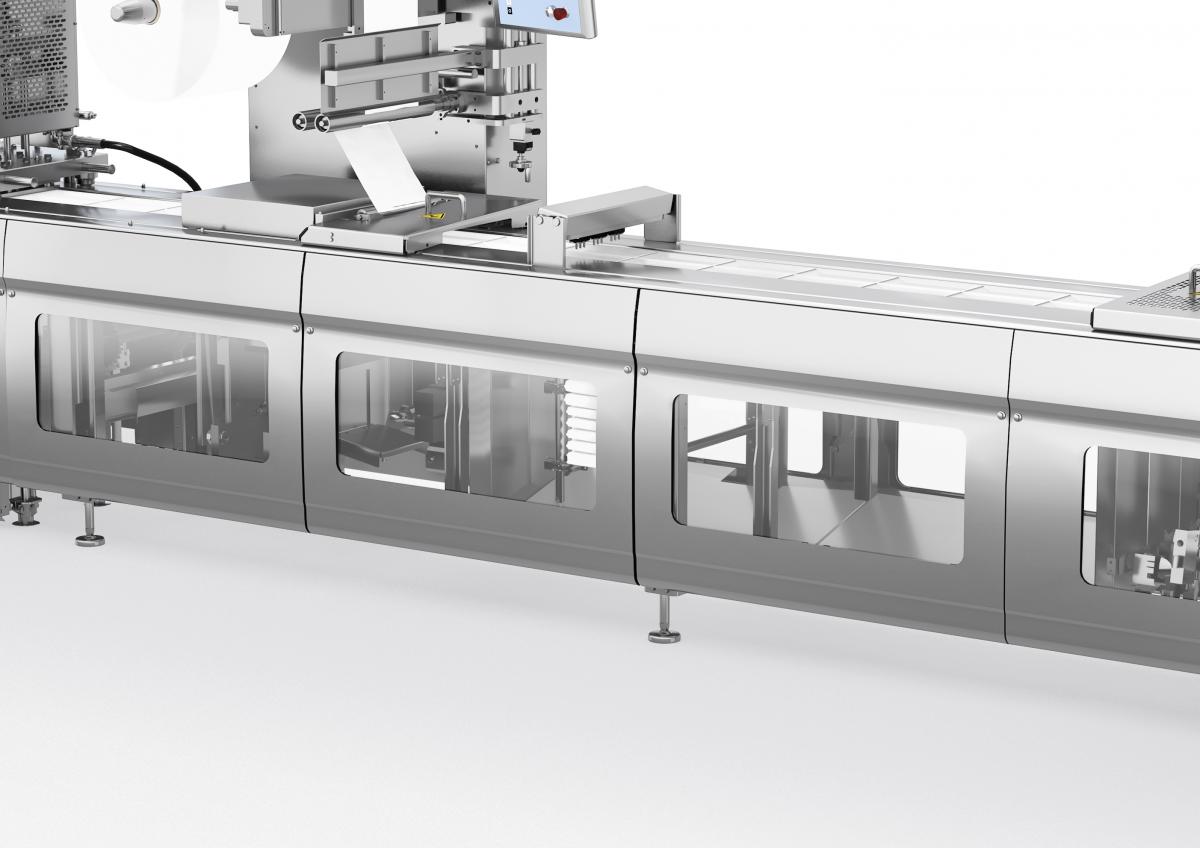

Carton forming, product loading and carton closing in one integrated unit

Bosch Packaging Technology and Kliklok Corporation will showcase the Kliklok ITC, an integrated topload carton forming, loading and closing solution.

Best for producers of confectionery, cereal bars, bakery products, biscuits and cookies, the ITC’s principal function is to form topload style cartons or trays and automatically load wrapped products into them, before closing if required. Comprised of a single fully integrated solution with three functions – carton forming, loading and closing – the machine helps to reduce customer footprint with an ergonomic design, avoiding the need to source three separate pieces of equipment, to interlink and integrate them. Another benefit of the ITC is the need for only one operator and one Human Machine Interface (HMI), which enables the productivity rate to be improved.

The ITC offers food customers the flexibility to change formats and run a variety of carton styles, and is designed for flow wraps, roll wraps, compartment trays or multi-packs. Cartons are fed using a reciprocating carton feeder, and are formed using a motion profiled vertical plunger. Either lock or glue cartons can be formed on the ITC, and four possible carton styles can be incorporated within a single or twin infeed model: three-flap carton with full flaps, three-flap carton with economy flaps, a single-flap carton or a tray.

Once the carton is formed, an intelligent transport system is used to carry it independently through the machine loading and closing module. This system provides flexible and variable configurable control of the carton to suit both loading and closing requirements, and is also comprised of minimal parts, reducing maintenance and increasing Overall Equipment Effectiveness (OEE).

The next step is the automatic loading of products, integrated into the machine using Bosch’s Delta robot. The appearance of a Delta robot is similar to an inverted three-legged tripod. The three segments or “arms” move independently of one another but share a common connection – the “robot hand”. This is moved by either extending or retracting one of the segments and enables Delta robots to reach every point within their range at the same speed at high accuracy. The robots do not need to struggle against gravitational and inertial forces and are therefore capable of extremely high speeds, and are able to track the carton transport system and load products ‘on the move’.

For the carton closing operation, a simplified lugless design eliminates carton carrying lugs, driven chains, mechanical transfers and timing flaps. Instead, the closing section uses easily replaceable high-friction belts to quietly convey cartons out of the machine, effectively reducing any carton marking and product damage.

Gebo Cermex

Hall 13/C47

New shaped-bottle infeed and collating system for robotic or traditional case packers

GEBO CERMEX is demonstrating its portfolio for the beverage and food, home and personal care (FHPC) customers based on its Agility 4.0™ program.

Marc Aury, President & Managing Director of Gebo Cermex, explains: “As a key player in the Factory of the Future movement with our Agility 4.0™ program, at interpack this year we are excited to give visitors a preview of our vision of the ‘Smart Machine’, with a comprehensive robotic/cobotic case packing solution embedding advanced and connected systems.”

A ‘Smart Machine’ features the latest motion technology, robotics and cobotics, auto adjustment and auto feeding, as well as being a connected machine, it establishes itself as a forward looking comprehensive solution. The ‘smart packing machine’ on display will feature four main innovative modules:

CareSelect – a new shaped bottle infeed system to preserve product integrity

Gebo Cermex will launch this patented universal and modular shaped-bottle infeed and collating system for robotic or traditional case packers at interpack. Utilizing Rockwell Automation’s iTRAK® technology and capable of achieving speeds of up to 400 products per minute depending on package size, shape and weight, the CareSelect system easily surpasses traditional ‘endless screw’ collation systems in terms of bottle integrity and protection. It delivers shaped bottles to the packing machine with precision and care in the correct orientation and pitch, turning each bottle 90°. Even unstable shaped products are smoothly and individually handled via independent movers. To eliminate contact between products, flow is managed without accumulation at the infeed and ‘friction time’ between the bottle and the system - when the bottles come into contact with machine parts - is dramatically reduced (by at least 20 times) compared to an endless screw infeed system.

Fenceless cobotic FlexiLoad for automatic magazine loading

The FlexiLoad™ is the reliable robotic solution for magazine loading, suitable for any case packing system regardless of type and speed. This eliminates the need for time-consuming, manual corrugated board magazine feeding and, importantly, the potential for operators’ musculoskeletal disorders (MSDs). The latest version enables a completely fenceless unit as it embeds the world’s strongest collaborative robot, the Fanuc CR35 with a 35 kg payload. Comprising a universal gripping tooling and PC based software, this version delivers a compact solution fitting in the same space as when the task is carried out manually. Yet, having no fence, the system ensures easy circulation around the magazine loading equipment and leaves operators free to carry out more skilled work.

WB46 Wrap-Around packing technology

The WB46 has a new automation platform, thermoplastic polyurethane timing belts and quick-release systems for format changeovers. These contribute to flexibility, hygiene and ergonomics.

Exclusively for interpack, Gebo Cermex will reveal a new on-the-fly robotic product loading station, which reduces the overall footprint of the machine by eliminating the need for a pre-collating system. This latest version of the WB46 will feature the company’s brand-new, user-friendly human machine interface (HMI), which is based on an intuitive, tablet-approach navigation and offers rich media tools for preventive maintenance procedures. On the booth, visitors will have a hands-on experience of a format changeover on the WB46, via virtual reality, demonstrating a new approach to operators’ training.

State-of-the-art digital connectivity and simulation

As part of the smart packing solution, the Equipment Smart Monitoring (ESM) system connects to the machine to read, transmit and organize performance data into a coherent dashboard. This system helps customers maximize the efficiency of component machines within their packaging lines (OEE): by operating at individual machine level and collecting a continuous stream of data via a connected measuring device, ESM gathers and analyses data to generate a number of key indicators. Based on these, engineers at Gebo Cermex are able to come up with recommendations tailored to clients’ exact requirements, to maintain and improve the efficiency of their installed base.

Meypack

Hall 14/B30

New case packer for small packaging units: The blank magazine with saw-toothed belts for the tray transport. (© Meypack)

THE FOOD industry is faced with a new challenge: to meet the increasing demand for small packaging units, and limited space in production facilities. With this in mind, Meypack is now offering a new development in case packing.

The case packer makes it possible to pack small, sensitive products into small formations while doing so on an extremely compactly designed machine that requires very minimal floor space. With its hygienic design, this highly efficient machine meets the stringent and high requirements set for food processing.

BEKUM

Hall 5 / D37

The HYBLOW 407 D, with the C-frame clamping unit patented by BEKUM, enables the reliable production of EPET bottles with flash removal and directed bottle transfer integrated in the machine

Extrusion blow moulding

BEKUM’s blow-moulding machines have been specially designed for high performance in EPET applications. The HYBLOW 407 D in particular allows the reliable production of EPET bottles with flash removal and directed bottle transfer integrated into the machine. The current 07 series of machines with the C-frame clamping unit, patented by BEKUM, is perfect for EPET processing due to the high closing force per cavity, uniform force distribution and extremely quick force generation.

The spiral distributor blow head technology from BEKUM features blow heads with uniform wall thickness distribution in the parison and in the end product. This results in a significant potential for packaging manufacturers to optimize the single-layer parison quality. The blow heads are ideal for items with a multilayer structure. The heads can be easily adjusted by the operator from the front of the machine. The head design enables faster color changing times compared to conventional designs.

Allen Plastic Industries Co., Ltd

Hall 8A/C34

Sleeving machine

FROM Taiwan, Allen Plastic will showcase a number of its packaging equipment including the ASL1000/2000 Automatic Sleeving Machine (Vertical). The machine boasts easy maintenance and operation, with HMI panel and simplified integration and consistent terminology. Versatile, the ASL can support product width ranges from 30-140mm. Built for durability, the machine is stainless steel and aluminum.

The company will also exhibit its Sleeve Labelling Machine for round bottles of any material via OPP label. It can label 150 to 300 bottles per minute for label sizes of 10mm -180mm (vertical width).

Paul Leibinger GmbH & Co. KG

Hall 5/Booth E24

The V-check vision system checks the marking and coding printouts from a LEIBINGER inkjet printer against a reference sample, increasing product quality as a result. (Photo: Paul Leibinger GmbH & Co. KG)

FROM its JET3up and JET2neo printer series, LEIBINGER will showcase the JET3up PRO with protection class IP65, making it ideal for package marking and coding for food in a wet or dusty production environment. The JET3up PI enables the reliable implementation of marking and coding of dark packages with white or light inks.

The JET3up RAPID is the company’s solution for high-speed production up to 1000 m/min.

The automated Sealtronic nozzle seal prevents the ink in the printer from drying out even during long breaks in production and provides a key benefit to customers on all LEIBINGER small-character inkjet printers. During a machine stoppage, the gutter and the nozzle form an airtight circuit: No ink can leak out of the circuit and no air can get in.

The automated JETmotion XY traverse system, when used with the WINJET3 XY software, enables the imprinting of entire product ranges from left to right and from top to bottom. This software calculates the optimum travel path on the XY linear system before printing and then adapts the path automatically to the quickest processing time. This saves time and makes production more efficient.

Also on exhibit, the company’s intelligent print and monitoring system from a single source that saves long-term costs. The V-check vision system can be used to carry out a quick and cost-efficient check of the product markings applied using a JET3up or JET2neo printer. To do so, V-check compares elements with fixed definitions, such as characters, numbers or graphics, to a reference sample in advance automatically and detects incorrect or smeared printing.

Mettler-Toledo

Hall 11, Stand B55

Mettler-Toledo’s two new checkweighing systems offer a performance increase of 30%

Protection, productivity and quality

METTLER-TOLEDO (MT) will present its product inspection solutions and upgrades for the food and pharmaceutical sectors at interpack. The company will demonstrate how focusing on protection, productivity and quality will help manufacturers improve processes and increase competitiveness in their markets. MT experts will focus on areas such as: improvements to brand protection and compliance, as the regulatory landscapes within food and pharmaceuticals become ever more complex; enhancing productivity and increasing operator efficiency to improve OEE; enhancing product quality through the detection of physical contaminants, ensuring accurate package weights, complete contents and correct labelling; plus, importantly, the safety of workers who operate inspection systems on production lines.

Mettler-Toledo’s stand will comprise four operational lines: general food, dry food, wet food, and pharmaceuticals. All four areas of product inspection technology are represented, with highlights including metal detection, checkweighing, vision inspection, X-ray inspection, and inspection management software.

MULTIVAC

Hall 5/Stand E23

The R 145 entry-level thermoforming packaging machine for jams and sauces

MULTIVAC offers an economical solution for producing portion packs. The company’s R 145 thermoforming packaging machine comes with an innovative shape and contour cutter, while the H 052 handling module is used to converge the packs and feed them to downstream process equipment.

Ideal even for small businesses or companies, Multivac’s solution offers cost-effective and highly efficient production of portion packs such as jams, salad dressings and sauces.

Thanks to short set-up times, the shape and contour cutter features a high degree of flexibility as regards the pack design, the format to be produced, and the packaging materials used. The cutting unit does not produce trim waste (there are no partitions at all between the packs), and contributes hugely to reduced consumption of packaging materials and therefore to lower pack costs.

The cutting system also enables packs with different shapes to be produced. It can be used on all thermoforming packaging machines.

The R 145 entry-level model is a freely configurable packaging machine in the medium output range. Built with standard configurations and pre-defined basic formats, it offers an excellent price-performance ratio.

The H 052 handling module for converging the packs from the cutting tool has a gripper that fixes the portion packs in place during the cutting process, then removes the good packs directly and completely from the cutting unit, before feeding them to downstream process equipment. Integrating the H 052 in the line control ensures that all relevant parameters from upstream processes are reliably transferred to the module.

Romaco

Hall 16/Stand D15

Romaco Kilian KTP series

FOR THE pharmaceutical industry, Romaco will launch the Noack NBP 950 blister packaging machine, the Promatic PCI 915 cartoner and the Kilian KTP 590X tablet press in line with the Siebler STF 120 tube filler.

The Romaco Noack NBP 950 blister packer is user friendly with a rotary sealing machine that is very easy to change over and clean. Format changes can be completed in next to no time.

The Siebler STF 120 rigid tube filling machine expands the company’s packaging portfolio for effervescent products. This redesigned system meets all requirements for quick and easy cleaning of the tube filler

The Promatic PCI 915 intermittent motion cartoner strengthens Romaco’s position in the secondary packaging sector. With its small footprint and maximum output of 150 cartons a minute, this machine represents the low-to-medium performance class

The Kilian KTP 590X rotary press is the newest model in the company’s KTP series. It is also the first single-sided rotary press specifically for compressing bi-layer and effervescent tablets.

RPC Group

Hall 10, Stand D21

The WaveGrip beverage carrier system

The Twist Cup was developed by RPC for Orkla Foods Norway’s salads

Prize-winning products

THE WaveGrip, the first genuine alternative to current beverage multi-packing solutions, and the WorldStar-awardee, Twist Cup with screw lid, are the latest in a long line of award-winning packs from the RPC Group.

A major theme on the stand will be RPC’s design and technical expertise in the creation of both standard and bespoke containers and closures, demonstrating plastic’s flexibility in producing solutions that deliver both superb aesthetics and complete functionality. The selection of packs on display will highlight this use of design combined with advanced manufacturing and decoration techniques to help create brand image and product differentiation.

Another important focus will be the availability of a variety of solutions to provide effective product protection and extended shelf life for food products. This ability to help minimize food waste will also be part of RPC’s sustainability message, underlining the different ways that plastics can contribute to businesses’ environmental programmes and CSR commitments.

The new WaveGrip solution is the most efficient and environmentally-sustainable beverage carrier system on the market, with the versatility to be adapted for all types of drinks businesses, from smaller artisanal producers to high volume operations. The applicator technology can improve line efficiencies by up to 30% while WaveGrip Carriers are produced using advanced lightweighting technology and strength-enhancing polymers to create a carrier that securely and efficiently collates product according to individual customer requirements. Carriers have been rigorously tested to meet the high standards of the retail sector, and enables easy pack reconstruction to avoid spoilage.

The Twist Cup from RPC Superfos and RPC Promens, which will receive its WorldStar Award 2017 at a ceremony during interpack, is an innovative packaging solution developed for a range of premium cold salads from Orkla Foods Norway.

The pack successfully mixes two different resin materials and two different technologies to create a thermoformed cup with an injection moulded lid. The result has similarities with a traditional glass jar which makes it stand out as something special in the cold salad segment. Despite the challenges that come from using two different resin materials, perfect compatibility between the thermoformed polyethylene body and the injection moulded lid of propylene has been achieved. The lid latches into the locking groove of the cup and, when closed correctly, the consumer hears a comforting click-sound.

tna

Hall 15/B22

For customers, tna is preparing a virtual tour on the entire production line of potato chips

tna has been employing virtual reality and augmented reality to present its products at exhibitions. Booth visitors can go on a virtual tour to fully immerse themselves into the production process of a complete potato chip line – from start to finish. At the same time, augmented reality will make it possible to bring individual systems to life and allow visitors to interact with them to find out more about their specific capabilities and features.

The company will share information on all its products, from cost-efficient steam peelers and high performance fryers to its gentle distribution, accurate seasoning, precise weighing and high-speed packaging solutions. These are designed for the snacks, confectionery, nuts, cereal, pasta and fresh and frozen industries.

Turnkey solutions from tna and its family of brands include:

Packaging: From completely integrated, high-speed vertical, form, fill and seal machines like the tna robag® FX 3ci to full washdown solutions like the tna arctic® 3, tna offers some of the most advanced and versatile packaging solutions in the food industry.

Weighing: Highly accurate multi-head weighing solutions bring the ultimate in efficiency, simplifying the weighing process while running wet or dry applications.

Potato processing: As the only single source supplier to the potato processing industry, tna offers complete processing lines for chips and French fries, including cost-effective pre-processing equipment, high-performance fryers like the Florigo conti-pro® or speciality batch fryers such as the FOODesign batch-pro®, all the way through to freezing tunnels from leading brand Ferguson.

Candy processing: Thanks to tna’s recent acquisition of Australian confectionery equipment supplier NID, tna is now also able to supply complete mogul lines, including some of the most innovative starch moulding systems and all the necessary ancillary equipment.

Distribution: horizontal and vibratory motion distribution systems like the tna roflo® HM 3 and the tna roflo® VM 3 will minimize product loss for optimal conveying of your product.

Seasoning: the tna intelli-flav® OMS 5 is the ultimate on-machine seasoning system that can provide both powder flavouring and liquid oil in a single drum, delivering consistent coverage and flavor to your product.

Inserting & labelling: Now available fully integrated into the tna robag packaging system, the Unique Solutions PouchPlus® 1000 and LabelPlus® 360 enable the high-speed application of promotional labels and/or insertion of value-added two-dimensional items, such as coupons, and three-dimensional items like toys or dry or liquid-filled sachets.

Controls integration: tna will also present its comprehensive controls integration and SCADA reporting technology in addition to its extensive range of site support, full project management and training services.

Micvac

Hall 10/D49

The Micvac method

THE MICVAC method for in-pack cooking and pasteurization is a continuous process that allows the producer to save on time, energy, waste and costs in all steps. The extended shelf life enables the producer to plan and be more efficient and it gives the retail the chance to have a wider product range.

The last years have also brought customers and projects not only working with single portion ready meals for the retail business, but also preparing components. “We see an increase in the demand for thermoformed products and pouches,” says Håkan Pettersson, Managing Director at Micvac. “This plus our new developments with two compartment trays, round trays, etc, give us an even broader portfolio than at the last show. Most customers still use our oval standard Flextray, but there’s an interest for more customer specific trays as well.”

The major advantages with the Micvac method are the quality and taste of the food, the extended shelf life and a very consumer friendly packaging. Consumer studies made in different countries in Europe state that the consumer perceives the difference compared to other products in the market. This encourages producers worldwide to choose the Micvac method for their chilled products. That it’s also a very waste efficient method is even more positive for the environment. There’s very little waste all through the value chain starting with the production, the shop and the consumer.

The origin of the Micvac method is production in a microwave tunnel. In 2016, Micvac launched a new business segment which is in-pack cooking and pasteurization in a combi oven instead.

More products at interpack 2017:

SIPA to showcase TSFL at interpack

BERICAP presents innovative products at interpack

interpack 2017

Date: May 4 - 10, 2017

Opening hours: 10am - 6pm

Location: Düsseldorf, Germany

Organizer: Messe Düsseldorf

T: +49 (0) 211 / 4560-7612

F: +49 (0) 211 4560-668

E: interpack@messe-duesseldorf.de

W: www.interpack.com

Nike