AS THE level of consumer diversity increases in Asia, finding the delicate balance between nutritional needs, portion size in relation to affordability, taste, and convenience are some of the core challenges faced by food manufacturers today. Greater consumer interest in nutrition and organic food items – superfood, gluten-free, functional food to name just a few popular terms – derives from the ageing population, health-conscious consumers in their 20-40s, and also parents with youngsters. Asia may be relatively slower in catching up with these newer trends, but with rapid urbanization and economic growth, the degree of consumer demand and expectation is set to grow exponentially.

To increase their shares in the food and beverage market, manufacturers are launching new products using a wider range of raw ingredients to develop a greater variety of taste, texture, and product offerings. Almond butter, coconut milk, and quinoa are among many newly-emerging ingredients that supported the manufacturers’ chase for product innovation in recent years. In the bakery and confectionery segment alone, a survey of the supermarket shelf showed ingredients like chia, flax, and probiotics are added to crackers, chocolates, and gummies[i] to make them healthy for consumption. This is an exciting movement for both Asian consumers and bakers because when more nutritional ingredients are added to the mix, new and unique flavors are created. While a wider range of ingredients can help differentiate a product, it is not all good news to bakers. With these ingredients come higher risks of cross-contamination, wrong ingredients being mixed, and more intricacies involved in bakery and confectionary processing. These challenges can be an added burden in terms of needing extra resources to ensure all equipment is up-to-standard for product changeovers.

Eliminating cross-contamination

With more product changeovers as well as the use of a greater variety of ingredients for baking, the risks of cross-contamination between different food substances increase. Costly recalls of baked goods due to undeclared allergens or the presence of foreign ingredients are more likely to be introduced along poorly maintained processing lines. This issue is, of course, not limited to Asia Pacific but across all markets. In fact, a new Bloomberg BNA analysis found that undeclared ingredients are now the number-one cause of food recalls ordered by United States Department of Agriculture (USDA)[ii]. The usual culprits of undeclared allergens in baked goods are eggs, nuts, and milk. Recent scandals to have hit the market involved the recall of icing sugar due to traces of almond found in the product not mentioned on the ingredients list[iii], and another where coconut milk ice cream was found to contain undeclared dairy allergen[iv].

Among the many causes of cross-contamination, one of Asia’s challenge in eliminating undeclared allergens from the food supply chain stems from varying interpretations and implementation of food standards among different countries within the region. Therefore, the initiative to harmonize food standards by the Association of South East Asian Nations (ASEAN) is an example of how some Asian countries have converged their regulations to comply with internationally recognized standards so as to better safeguard consumers’ health on a global scale[v]. By extension, bakers can make sure that global food safety certifications such as USDA and Global Food Safety Initiative (GFSI) are met within their facilities to help demonstrate their commitment to the wellbeing of consumers, and secure consumer preference while protecting the credibility of their brands. Safety assurances for conveyor belts and maintenance equipment are no exception.

Dough falls from the conveyor

Frosting build-up causes the conveyor belt to mistrack, and the abrasive quality of the sugar in the frosting leads to premature wear that significantly shortens belt life

Caught in a sticky situation

Plastic modular belts like PVC and PU are preferred by bakers in dough processing for their resistance to fat and oil. However, such resistance cannot prevent the food scraps and remnants building up on the conveyor’s pulleys and structure from sticky goods, sugar and icing, and powdered residue from cereals, grains, biscuits, and chocolates from occurring – a common yet complex issue in conveyor belt management for baked goods. Many manufacturers find themselves having to attend to unsatisfactory sanitation using home-made cleaning solutions, or adopting costly corrective measures by replacing belts once or twice a month. Corrective measures require more capital and human resource investment. Yet, even more crucial is that without putting in place an effective and reliable preventative measure, unsatisfactory sanitation can lead to the wrong ingredients being unintentionally included in a product. This can be an issue if sticky residue stubbornly persists along the processing lines.

Here are two classic “sticky” situations in bakery and confectionary scenarios:

(i) Breakfast pastries scenario

Sugar frosting on breakfast pastries adhere to the conveyor belt and keep rollers and other parts of the belt from functioning properly. The build-up causes the belt to mistrack, and the abrasive quality of the sugar in the frosting leads to premature wear that significantly shortens belt life. The sticky nature of frosting is also a nightmare for bakers due to the amassing of residue on parts of the belt, making it challenging for proper sanitation.

(ii) Potato chip dough scenario

Dough is naturally wet and sticky and there is no way to avoid this. Adhesion of the dough on the belt and accumulation of carryback is a constant challenge for all bakery and confectionery processing facilities. Manually scraping off dough on the belts is manpower intensive, and using homemade cleaning solutions produces a lot of waste material and can result in a lot of unnecessary downtime in between product changeovers.

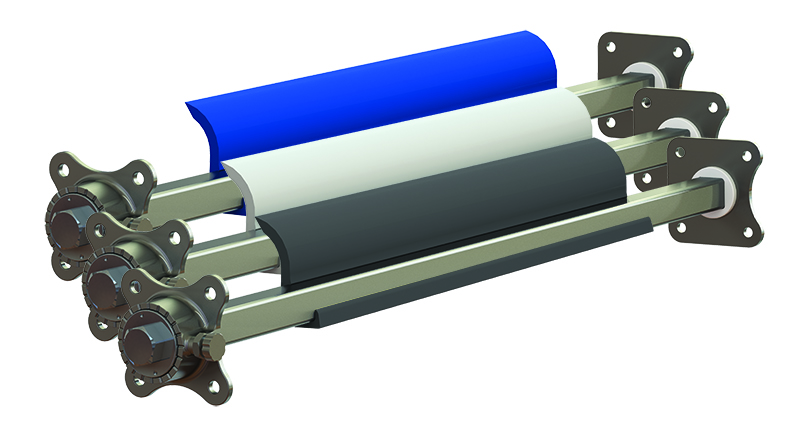

If such situations are constantly resolved using corrective measures such as belt replacement each time frosting or dough usage is maximized, the replacement may happen every two weeks for a number of processing lines depending on the size of the facility. Engineered cleaning solutions today ease the removal of the frosting and any residue left on the belt as it operates, so that sanitation is not compromised over the course of bakery and confectionary processing. For instance, with the Flexco FGP Food Grade Precleaner – constructed with only FDA-approved materials and USDA certified for meat, poultry, and dairy applications – carryback is scraped and removed, preventing accumulation on the rollers and belt system components. At the same time, ease of-install, maintenance, and disassembly results in a reduction of downtime and the manpower required for sanitization. Preventive measures allow less carryback and reduce wastage of food materials, which eases maintenance efforts.

Flexco FGP Food Grade Precleaner is constructed with FDA-approved materials. Carryback is scraped and removed, preventing accumulation on the rollers and belt system components

Baking to perfection

While food manufacturers continue to explore healthy food alternatives, flavor remains at the core of product innovation in emerging spaces such as bakery and confectionery[vi]. The perfect recipe to constructing a tasty, clean and healthy brand image begins with proactive regulatory compliance that meets industry needs and standards for high quality and safe-to-consume baked goods. Flexco’s expertise in effective conveyor belt maintenance and sanitation can support bakers in keeping up with Asia’s evolving consumer demand for an assortment of flavors by ensuring that the taste of baked goods remains uncompromised during frequent product changeovers. By maintaining a robust hygiene upkeep dedicated to overcoming sticky situations along the processing lines, bakers can enjoy faster production cycles and higher throughput rates, leading to improved productivity and decreased downtime – ultimately achieving higher profit.

*Jerry Loh is general manager at Flexco Southeast Asia

[i] https://www.thinkwithgoogle.com/articles/2016-food-trends-google.html

[ii] http://www.bloomberg.com/news/audio/2016-08-09/undeclared-allergens-are-the-leading-cause-of-food-recalls

[iii] http://www.foodmanufacture.co.uk/Food-Safety/Food-recalls-sparked-by-milk-and-nuts

[iv] http://www.channelnewsasia.com/news/singapore/cocoluscious-products-recalled-due-to-undeclared-dairy/3126572.html

[v] https://foodindustry.asia/documentdownload.axd?documentresourceid=659

[vi] https://foodindustry.asia/a-look-at-food-and-drink-trends-in-the-asia-pacific-region

Tubular Doom Sock