As the main component of Coperion's eccentric pelletising systems known as EGR, a new type of knife rotor enables the production of extremely low-dust PVC pellets for cable production. Rotating directly on the die plate of the EGR, and fitted with pelletiser knives that have also been optimised, the rotor (patent pending) permits particularly smooth and gentle cutting of temperature and shear-sensitive plastics. This greatly improves the quality and further processability of the pellets produced as compared to the types previously available.

To achieve this recent development, Coperion specified a special metal alloy and design for the production of both the new rotor and the knives mounted on it. Due to these technical optimisations the knives remain in particularly even contact with the die plate during operation. The result is very high cutting quality that forms the basis for achieving the desired substantial reduction of the proportion of fines in the pellets.

Proportion of fines reduced down to detection limit

As a general rule, the occurrence of such fines essentially depends on the PVC recipe used and the knife arm speed required to attain a particular pellet length. In practice it is possible to reduce the quantity of fines by adjusting the knife rotor, but not avoid them altogether. The consequences of these fines becoming detached during pneumatic conveying of the pellets is both increased waste and severe contamination of the conveying pipes and the cooler. A good deal of work and time may then be required for cleaning to avoid contamination on next product change.

By contrast, Coperion's new knife rotor/knife combination, thermomechanically optimised in the course of extensive simulation and trials, makes it possible to reduce the proportion of fines almost down to the detection limit across the whole spectrum of throughput rates and cutting speeds tested. The new EGR knife rotor is currently proving its worth to our customers in pilot applications.

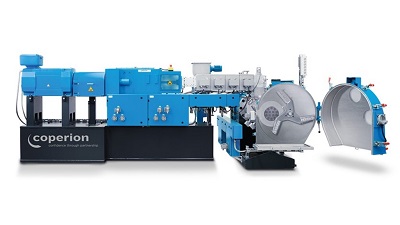

Coperion developed the EGR eccentric pelletiser especially for operation in conjunction with its Kombiplast KP two-stage processing systems. With the combination of a twin screw extruder ZSK and a single-shaft discharge screw ES-A, these ensure the gentle build-up of pressure required by shear-sensitive compounds being pressed through the die plate of the EGR. All this adds up to a reliable, proven technology for the gentle and economical processing and pelletizing of hard and plasticized PVC recipes, as well as of HFFR recipes or elastomer-based cable compounds. Coperion can draw on decades of experience in the design and construction of complete plants for the processing of temperature and shear-sensitive materials – from material handling and feeding, to dry blend production, compounding, and pellet cooling, to storage and filling.

Coperion will be presenting the new knife rotor for the first time at Wire 2018, taking place in Düsseldorf from 16 to 20 April.

Air Jordan