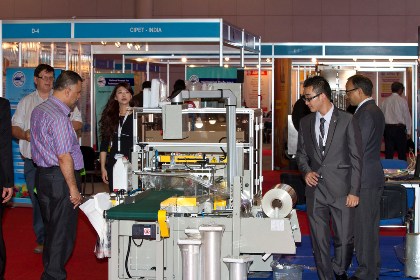

The 3rd Plastivision Arabia 2016, to be held at the Expo Centre Sharjah from February 22 to 25, will showcase leading global manufacturers and several technical innovations that can generate outstanding output with minimum power consumption and faster return on investment. Leading companies are expected to demonstrate the power of their latest technologies aimed at the dynamic plastics industry in the Middle East.

“Plastivision Arabia has come to be known for introducing a wide range of new technology, which has found ready takers in the region. In fact, Plastivision Arabia has acquired a unique reputation for seeing all its machines and equipment on live display being sold even before the show comes to an end,” said Mr. Saif Mohammed Al Midfa, CEO, Expo Centre Sharjah. Mr. Midfa further said that regional plastics processors have readily accepted anything that helps them cut down the usage of virgin raw material and thus reduce production cost. For film producers, the ABA blown film technology is a great replacement of monolayer machines.

In the region, blown film extruders mostly are mono-layers, and industry observers point out that converters are currently investing in new multi-layer extrusion processes. ABA is extremely competitive for manufacturing garbage & shopping bags, shrink film (for bottle wrapping), construction film and t-shirt bags, among others.

Polystar is one such international company that will exhibit its blown film extrusion and recycling lines -- Eco-Flex, the ABA blown film technology that produce a thinner, stronger film at substantially lower production cost.

Technically, in ABA type film, the outer and inner layers will be of the same polymer fed by the same extruder and a middle layer will be of a different polymer that will be fed by a second extruder. A high percentage (up to 50-70%) of calcium carbonate compounds or recycled material can be used in the middle layer of the film, thus cutting down the usage of virgin raw material and reducing production cost.

Polystar, which is a globally recognized machine manufacturer of plastic recycling, blown film extrusion and sealing machines in Taiwan, will also provide high-level of customization, depending on the requirement, space and budget of prospective clients. Polystar is part of the impressive line-up of Taiwanese exhibitors that have confirmed their participation, including Lung Meng, Matila, KWT, Seal Pack, Auger, Long Durable Machinery, Hao Yu, Chum, San Tung, Pack Leader, Atlas, Kung Long Hong, Inora, Chuan Peng, Vpet and Hemingstone, among others.

Visitors to the show will be able to see live how the ABA blown film technology works and order the machines directly.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login