Recently, plastics manufacturing has seen rising demand for high-variety, low-volume production environments. The introduction of Quick Mold Change System (QMCS) in injection molding will help manufacturers increase production, improve efficiency, stabilize quality, save cost, and support upgrading to a fully automated production, according to HVR Magnetics Co., Ltd. General Manager, Davisn Ren in this interview with International Plastics News for Asia (IRNA).

Mr. Davisn Ren, General Manager

IRNA: Through automation to reduce costs and improve productivity, manufacturers could stay a step ahead of the competition. What role will QMCS play in the production process?

Mr. Ren: A product in the process of injection molding often requires using a number of different molds to shape, the higher the complexity of the product, the higher the mold change frequency. To shorten the mold change duration and achieve a faster responsive delivery, the application of QMCS in an injection molding machine becomes more important. However, the traditional clamping, including the pressure plate clamping and hydraulic clamping, still has a lot of disadvantages such as high security risks, low reliability, easy deformation of the work process, product consistency, and high labor costs, etc.

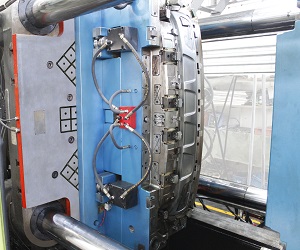

HVR Magnetics specializes in manufacturing electro permanent lifting magnets, electro permanent magnetic chucks, electro permanent magnetic welding fixtures and quick mold change clamping magnets. The use of electro permanent magnet technology in the injection molding machine QMCS can substantially shorten the mold change duration and save energy. It can also resolve many shortcomings of the traditional clamping, such as avoiding mold deformation during installation, high product consistency, easy to clean, etc. In addition, the electro permanent magnet QMCS can be more secure, reliable, higher clamping accuracy, lesser mold wear, therefore extending the service life of the mold.

IRNA: How will HVR Magnetics support the Made in China 2025 goals?

Mr. Ren: HVR Magnetics Co., Ltd. is one of the earliest electro permanent magnet technology suppliers for the plastics industry in China. We have supported the shift to adopting electro permanent magnet technology to replace the traditional mode. This has ensured that plastic manufacturers recover their one-time investment in a short period of time while reducing production cost and inventory, thus improving business competitiveness.

HVR Magnetics provides full product customization according to its customers’ special need and their operating practices. Also, HVR Magnetics’ products – from production, assembly, testing to packaging - are under strict check and supervision so as to achieve the highest quality.

Advanced quick mold change system enhances production efficiency.

IRNA: What are the company’s contributions to achieve lean manufacturing?

Mr. Ren: Lean manufacturing removes and minimizes non-value work activities from the process to eliminate wastage. The implementation of lean manufacturing allows us to streamline the company's process from the production to the distribution, eventually reducing manufacturing costs and speeding up product delivery. The key element of lean is "continuous improvement", which means that all the company members have to continue to strive for excellence.

Along with the Made in China 2025 strategy, China's manufacturing industry is set to upgrade toward Industry 4.0 to achieve intelligent manufacturing. MVR Magnetics has found that the Made in China 2025 strategy is full of challenges and opportunities.

IRNA: Is the company expanding into emerging markets?

Mr. Ren: It is an inevitable trend for enterprises to continue to expand their markets. The overseas business of HVR Magnetics is also growing, and has been exporting to Europe, the United States, Japan, South Korea, Southeast Asia and the rest of the world. We not only offer products and technical services but also aim to maintain a sustainable competitive advantage. As a result, we continue to improve product quality, innovation with investment focused more on long-term benefits to find our interest growth point targeted at the international arena.

Nike Zoom Kobe IV

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login