Indian film producer Flex Films has been eyeing a major share in the growing global pharmaceutical films sector. Known for innovating products, it has recently been bestowed with United States Patent covering entire categories of Formable Films that include one or more BOPET layers used in Alu-Alu blister packaging.

The patent registration to its credit protects innovation and curbs malpractices prevalent like copying, reverse-engineering or selling product without its nod. Moreover, silver bullet brings more protection for a pre-determined period and keeps the company a step ahead of its competitors.

Established in 1985, Uflex Limited is India’s largest multinational flexible packaging materials and solutions company and an emerging global player. Uflex global film manufacturing arm, Flex Films, operates state-of-the-art film manufacturing facilities in all the four major continents - Asia, Europe, North America and Africa - with cumulative production capacity in excess of 337,000 MT per annum.

The man responsible for driving the company to playing a key role in the company’s R&D efforts, Mr. Pramod Sirsamkar, President – Technical & New Product Development (Films) shares with the International Plastics News for Asia (IRNA) the company’s operations and how it has targeted the wider global market.

Mr. Pramod Sirsamkar, President – Technical & New Product Development (Films), Uflex Limited

IRNA: When was exactly the patent granted in the US market and for how long?

Mr. Sirsamkar: The patent US 10131122 was issued to Flex Films (USA) Inc. on November 20, 2018 for a period of 20 years, lending a competitive advantage to the films business of the company over its opponents in cold-formed pharmaceutical packaging industry. With the patent issuance, the company gets exclusive right to the manufacturing and sale of this special BOPET film in the United States. The patent is also filed in Europe and India, so by this we also have right to sale there.

IRNA: Please elaborate on the elimination of PVC from the film structure and how it makes the new BOPET film environment-friendly.

Mr. Sirsamkar: With this innovation in pharma packaging and particularly for Alu-Alu blister laminate structure, BOPET film has completely replaced the carcinogenic PVC. The PVC releases poisonous gases like dioxin and hydrochloric acid during recycling or reprocessing, which are regarded as hazardous for human health. Besides, when PVC comes in direct contact with sunlight, it gives away chlorine gas. This gas affect troposphere, the first layer above the surface and contains half of the earth's atmosphere. Whereas the special polyester film can be recycled and reprocessed and is 100% environment-friendly. Likewise, this BOPET film has also replaced 25 microns BOPA film. Against 0.4 % moisture absorption of BOPET, BOPA film has moisture absorption of 8 -10 %. During the lamination of BOPA film with Aluminium foil, if humidity is not controlled, the moisture is absorbed by BOPA film. The entrapped moisture results to delaminate BOPA film from Aluminium foil. On the other hand, BOPET does not absorb any humidity and doesn’t need any special conditions to process or store.

IRNA: What kind of structural changes have been made in the new Alu-Alu laminate blister pack?

Mr. Sirsamkar: Currently, film is structured as 25 microns OPA, 50 microns aluminium foil and 60 microns PVC, which is now replaced with 36 microns PET, 50 microns aluminium foil and 36 microns PET eliminating PVC component altogether to make it eco-friendly.

IRNA: What other unique features are introduced in the new BOPET film

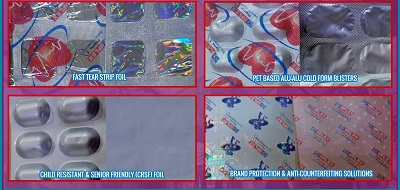

Mr. Sirsamkar: The BOPET film, delivers a huge saving on carbon footprints and energy consumption. Moreover, it could be easily printed with many different types of inks, an advantage compared to PVC and BOPA. Considering, it is difficult to read the details of drugs printed on aluminum foil of blister packs even today, the compatibility feature of BOPET film with the different types of inks used in printing, communication of drugs on blister packs has become readable now. The film has also opened up many avenues to evade the menace of anti-counterfeiting.

BOPET film meets the high standards in flexible packaging.

IRNA: When did the development work from the R&D team commence on the product?

Mr. Sirsamkar: We had started working on it about one and a half year ago and succeeded in developing it about seven months ago. We have strengthened our intellectual property protection with the addition of this patent. Our R&D team in film business comprising of 15 scientists at Noida site and another 15 at Kentucky plant in the US consistently worked to invent on the now patented special polyester film that since its launch last year has changed the landscape of medical packaging reducing the dependency on BOPA and PVC films use in Alu-Alu laminate blister pack. This patent undoubtedly would be a game changer for our business and will prove to be an asset not only for us, but also for the pharmaceutical industry.

IRNA: Has the product been introduced in the domestic market?

Mr. Sirsamkar: Yes, the product has already been introduced in 20 different companies and was well received in the domestic market.

IRNA: How long will it take for the new film to be fully accepted and applied in the market?

Mr. Sirsamkar: Even a normal flexible film qualified for different convertors and end-users takes about 6-7 months and in case of pharma film, it may take even longer as stabilisation study is required before its adoption.

IRNA: Is there any plan for further capacity expansion in the near future?

Mr. Sirsamkar: There are no immediate plans for a capacity hike as currently the Noida plant where the new product is being manufactured has a capacity utilisation rate of about 80%, therefore, there is enough installed capacity for the new product at the moment.

IRNA: What is the size of the global pharma packaging market in terms of value and volume annually?

Mr. Sirsamkar: The global pharma packaging market is estimated to be around $75 billion annually, and Alu-Alu blister packaging is worth $22 billion with the North American and European markets having about 25% share each and the Asian market with 30-35% share.

Uflex presents the “next big thing” in pharma packaging

IRNA: When will the product hit the US market? Are there plans to launch the product in Europe, too?

Mr. Sirsamkar: The product would hit the US market in the next quarter as we are in the midst of identifying convertors that would bring the product to end-users.

We will launch the product in Europe simultaneously with the US market. Currently, we are also talking to prominent convertors in the European market to introduce the product to the end-users there. We are in touch with some of the biggest names in the business and hope to get the breakthrough soon.

IRNA: What new products in the film vertical are in the pipeline?

Mr. Sirsamkar: Flex Films is regarded as an innovation driven company and our R&D team is working on strip packaging for the pharma sector.

IRNA: What are Uflex current capacities on the film side?

Mr. Sirsamkar: We have 60,000 tonnes annual BOPET capacity and growing at 6-7% yearly. We have about 13-14% share in the overall estimated Indian capacity of 450,000 tonnes and aspires to have 20% share in the domestic market. We have about 15% share in the pharma segment and target a 50% share in the next five years. IRNA

Uflex Limited

A-1, Sector-60, Noida-201 301, (U.P) India

Tel: +91-120 400 2121, 6100000

Mobile: +919810357059

E-mail: sirkamkar@flexfilm.com

Website: www.flexfilm.com

Nike Lebron 10

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login