The first manufacturers were craftsmen who worked in their homes making essential items like clothing, glassware, bowls and furniture for their own use. Every product was made to order and was one of a kind. Moving beyond basic subsistence, entrepreneurial craftsmen made multiple copies of their homemade products for others.

Then craftsmen began to work in groups in facilities served by a common resource such as a blacksmith forge or glass furnace, increasing production efficiency many fold as well as providing other benefits such as technique sharing. Output also increased when a centralised source of energy such as water wheel power, steam or electricity was distributed throughout a factory.

The early factories produced parts one at a time. The manufacture of multiple uniform products began with the development of assembly lines, where each worker repeatedly performed a separate operation as the product was passed from one workstation to the next until completed. This was the beginning of mass production: reliable output of large numbers of identical – at least according to the manufacturing tolerances of the time – products. Perhaps the ultimate expression of the assembly line concept is the automotive transfer line that turns out thousands of identical parts around the clock and for years at a time.

The rise of product marketing upset the mass production scenario. In the heat of capitalist competition, marketers sought to expand their customer populations by offering products altered to fill the demands of smaller market segments.

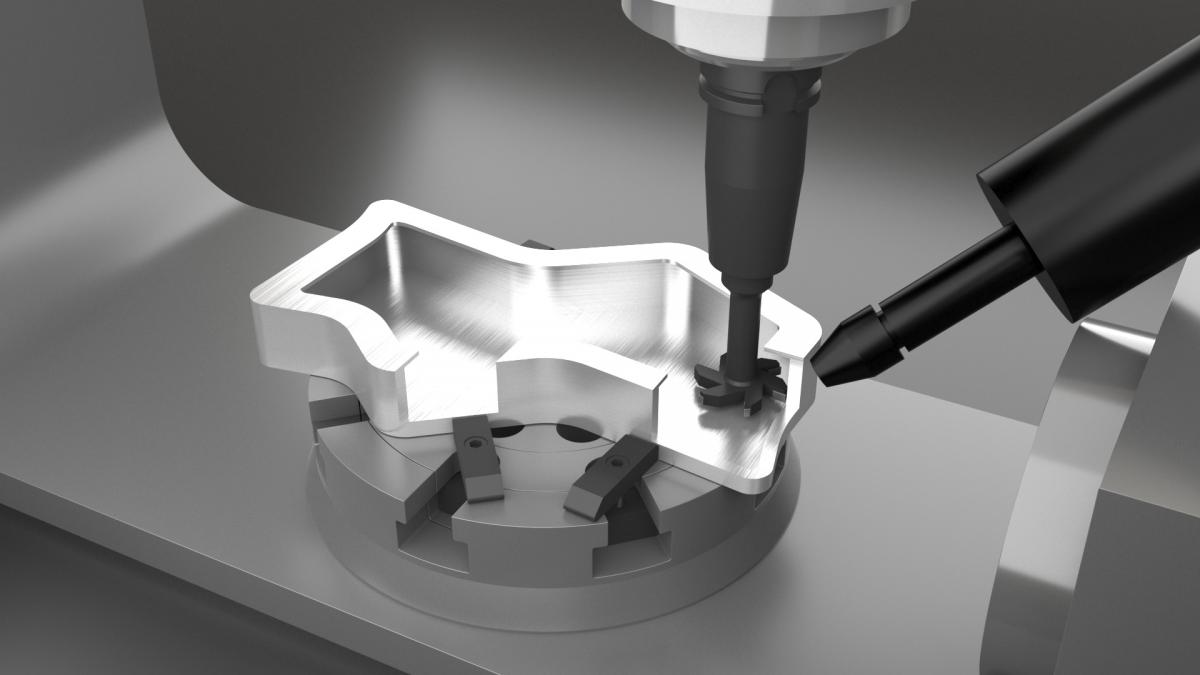

A perfect example is when early automakers changed from the any-colour-you-want-as long-as-it’s-black marketing philosophy of the Ford Model T automobile to offering customers an ever-widening choice of colours and options. To fulfil such individual consumer demands, manufacturers had to be flexible and find ways to efficiently change over between different manufacturing processes. Numerical machine control via punched paper tapes, and later computer-driven numerical control, provided the ability to change processes and tools rapidly and reliably. At the same time, increased capabilities of automation systems cut part handling time and labour costs. In the last few decades CNC manufacturing cells that switch between producing different parts or part features with the touch of a few buttons have, for the most part, replaced the reliable but difficult to modify transfer line concept.

Trends in consumer product marketing clearly illustrate the advantages of computer-aided manufacturing flexibility. By simply reprogramming elements of a manufacturing line, marketers can create many brand extensions. And the trend towards individualisation is not restricted to manufacturing. For example, large retailers are opening smaller format and specialised stores aimed at individual consumer convenience and product preferences.

Individualisation of manufacturing output will only grow more common. Similar to the implementation of Industry 4.0, models in the cloud may use marketing information to manage product changeovers, automation and inventory levels. Also similar to the operation of cloud-based cutting process systems, human marketers will still need to oversee these marketing-driven manufacturing systems and ensure that the systems’ decisions make sense.

Most recently, additive manufacturing technology is enabling individuals to produce custom-designed parts in a home setting. So, in sort of a full-circle evolution, manufacturing driven by digital information now enables production of one-of-a-kind items without a factory, like those made by the centuries-ago craftsmen but at unprecedented levels of precision, quality and speed.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login