A lot of advances in the modern world, most of which are launched in this era, are in the fields of medical and healthcare. One innovation that has revolutionised the industrial arena and is believed to become mainstream in the next few years or so is the development of 3D printing as applied in the field of medicine.

The healthcare 3D printing market is forecast to breach the $5.5 billion mark by2024, according to a recent report by Market Research Engine. 3D printing, also termed as additive manufacturing, is a technique for converting virtual 3D models into real time 3D objects. According to the report, technological innovation and advancements has evolved as preclinical drug trial by promoting testing on 3D printed organs as an alternative to animal examination. Human services 3D printing market gives huge chances to assembling different medicinal devices and equipments including prosthetic limbs, dental inserts, orthotic footwear and hearing aids.

Specifically, 3D printing offers huge opportunities for the production of different medical and pharmaceutical products which can have transformative implications in the advancement of healthcare. “3D printing is a highly versatile manufacturing technology that can create unique multicomponent architectures and functional devices, which cannot be fabricated with conventional manufacturing techniques,” according to Yong Lin Kong, a former MIT postdoc who is now an assistant professor at the University of Utah.

3D printed pills for epilepsy patients

Upgraded printer for customised products

For starters, the G3DP2 printer, or the printer that was able to conceptualise the idea of 3D printing through the use of molten glass, has been undergoing thorough research and upgrades to accommodate more advanced fields such as architecture and the like. This will be done by improving the speed, scale, and overall capacity for use and reuse of the machines themselves, and of course, further understanding on how to control the behaviour of the printed glass itself.

Although the main focus of the upgraded printer is more on the industrial side, there has been many proposed theses and hypotheses on utilising more advanced 3D printing for medical uses. For example, there are methods of 3D printing that could be used for the development of prosthetics, tissue and organ fabrication, and implants that could be more suitable to the patient than non-automated ones. There are also more uses which could be a better solution to the 3D visualisations that surgeons and dentists use, both for training and the pre-surgery work itself. Even CT scans or MRI volumetric medical images could be replicated, and can be more well represented with the use of 3D printing.

There are also various applications in terms of its ease of access for those who practice medical professions in creating more customisable tools for surgeons, for example. Eventually, it has also been anticipated that pharmaceutical products such as various medical drugs, syringes, etc. will more likely be cost-efficient, and hopefully more effective, due to its customisable feature which allows a more controlled medical environment for patients in terms of their dosages, etc.

Improving ingestible capsule

Massachusetts Institute of Technology (MIT), Draper, and Brigham and Women’s Hospital researchers have created a state-of-the-art ingestible capsule that can be monitored through Bluetooth wireless technology. This customisable innovation can both deliver drugs and detect environmental conditions while residing in the stomach for at least a month. Medical information is transferred to the user’s smartphone followed by the corresponding instructions based on what was gathered. The manufacturing technology used in the creation of the capsule is 3D printing. The capsule is set to deliver drugs, mainly those that are consumed in a long-term, that could help in treating a variety of diseases. This could also help patients maintain the strict dosing treatments required for patients with HIV or malaria. This can be customised according to what information is needed.

3D printed ingestible capsule that can be monitored through wireless technology

One capsule can easily detect infections, allergic reactions or other medical issues, and then release an appropriate drug in response. The capsule’s system has the capacity to provide closed-loop monitoring and treatment, thereby producing signals whenever a delivery or dosage of drug is needed. The device is a means of communication for wearable and implantable devices that pool medical information from the patient to the doctor’s smartphone.

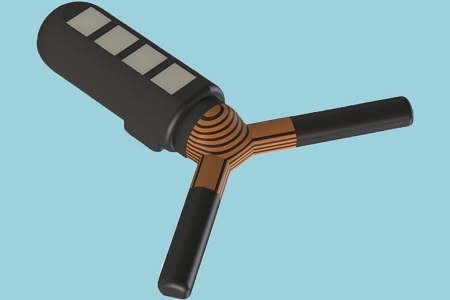

The features of the capsule have been developed since 2016. It was first designed as a star-shaped capsule with six arms that fold up before being encased in a smooth capsule. Once swallowed, the capsule dissolves and the arms expand, making the device to land in the stomach. But after some developments, the star-shaped with six arms became a Y-shaped one. This capsule can remain inside the stomach for at least a month, before it slowly breaks into tiny pieces which then passes though the digestive tract. One of the arms includes four small compartments that can be loaded with a variety of drugs. The drugs can be packaged out of polymers that allow them to be released gradually over several days. The design of the compartments can be opened remotely through wireless Bluetooth communication. The device has sensors that monitor the gastric environment and relay information via a wireless signal. The 3D printing approach easily combines all the components carried by the capsules and build the capsule from alternating layers of stiff and flexible polymers, for it to survive the acidic atmosphere of the stomach.

The researchers are continuously working on developing other kinds of sensors that could be incorporated into the capsules. They tested the temperature sensor in pigs and they were able to conclude that within about two years, they may be able to start testing ingestible sensors in human patients.

3D printed epilepsy drug

Another notable drug that came about due to 3D printing would have to be an epilepsy-related drug. Most epilepsy patients find it difficult to swallow pills due to their given state. The 3D printed pills are another version of one of the most commonly prescribed drugs, an anticonvulsant Levetiracetam, which is designed to melt in the patients mouth once taken with water, thus making it easier for epilepsy patients to swallow. The drug is manufactured by Aprecia Pharmaceuticals, a 3D printing, pharmaceutical company. Around August 2016, the US Food and Drug Administration (FDA) accepted the 3D printed drug and has been out in stores. The drug was marketed as “Spritam” and has been known as the first 3D printed drug.

However, the drug has a special printing technique to make sure its quality is kept in check. A printing technique that the Massachusetts Institute of Technology (MIT) developed involves building a pill one layer at a time. This is done by spreading powdered medication and depositing liquid on each layer until the dosage is sufficient. Around 1,000mg of medicine could be layered into this pill. The porous nature of the pill could also benefit people with other kinds of sicknesses similar to epilepsy such as cerebral palsy or Alzheimer’s disease. This is because of the drug levetiracetam, which could be used as an adjuvant therapy for a lot of kinds of seizures, and epileptic spasms.

These conceptualised then actualised medical advances due to 3D printing implies that 3D printing has a budding impact in the medical field. The applications at the present time have already proven to be extremely useful, and incredibly helpful in terms of reducing the resources required for some operations, cutting the cost needed to perform these operations, accurately representing anatomical and medical data, and of course, constructing various artificial medical solutions. 3D printing has been promoting efficiency and effectiveness when it comes to manufacturing products. It has paved the way for a better health care system. There has been an incredible amount of capability for 3D printing to overcome future challenges in various applications.

Adidas

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login