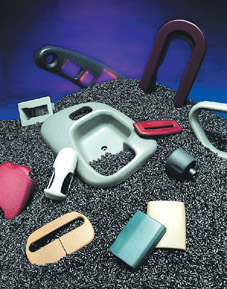

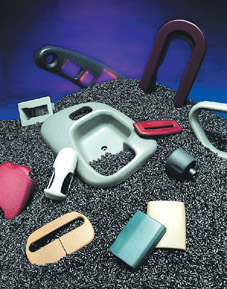

The market for colorant and additive concentrates (masterbatches) continues to grow. About 55% of the coloring aids are black (24%) and white batches (31%), with other colors accounting for about 25%. The most important fields of application are found in the automotive industry, in the packaging sector as well as in the production of household appliances and their components. Approximately 55% of masterbatches are used for conventional polyolefins. PVC consumes about 20%, while styrene-based resins such as PS, ABS, SAN and their blends account for some 10%. Engineering resins are responsible for about 6%; other resins such as high-tech materials consume roughly 9%. Some 50% of masterbatches are consumed by injection molding, about 20% by extrusion, and approximately 15% each by blow molding and other processing methods. The current state of affairs In terms of the production, the plastics sector has been undergoing a process of consolidation worldwide for some time now. At the same time, the remaining companies are attempting to reduce their product range to a few standardized resins that can be produced in volume. Only specialty suppliers and compounders are in a position today to supply smaller quantities of products to satisfy special requirements. The above mentioned consolidation process is also being accompanied by a movement toward concentration on the processor side. The previously medium-sized plastics processors that were typical are in the process of becoming larger companies that, like their customers, operate globally. The medium-sized company will, in the future, more likely be the exception than the rule. Smaller processors will survive only if they can find niches for themselves that require a higher level of technical know-how and processing capability in terms of machinery and materials. Masterbatch suppliers must already confront these processes today: be it color tones that must be available around the world, be it a consolidation process affecting the rest of the industry as a result of economic pressures that impact both the company and the range of available products. Moreover, it will become increasingly important for the masterbatch industry to perform tasks that in the recent past were still the responsibility of the resin suppliers. This often means occupying those open areas at plastics processors that are no longer handled by the resin suppliers because of the "concentration on the core business". Responsibilities here range from design development through support during the release process for a material to feasibility studies, i.e. to answering the question as to whether a particular material is suitable for a specific application. Consequently, the masterbatch supplier is increasingly confronted with the task of also fulfilling the role of material qualifier for its customer. According to estimates by market mavens, the following structures have crystallized on the side of the colorant and additive concentrate suppliers since the start of the new millennium: The internationalists: This category includes first and foremost suppliers such as Cabot Plastics International and Ampacet that offer primarily standard products (black and white batches, additives and colorants) in large volumes. For the above mentioned commodities, orders are issued largely on the base of price. On the other hand, there are also suppliers who offer a wide range of specialties but can, if necessary, provide larger volumes as well. In terms of products and processes, these suppliers focus above all on fiber, packaging, blow molding, injection molding and extrusion. Companies that target these market segments include, among others, PolyOne as well as Clariant Masterbatches. This group of suppliers obtains its orders largely as the result of a specific support or other service as well as its innovation capabilities; material price is only oAdidas Falcon

The market for colorant and additive concentrates (masterbatches) continues to grow. About 55% of the coloring aids are black (24%) and white batches (31%), with other colors accounting for about 25%. The most important fields of application are found in the automotive industry, in the packaging sector as well as in the production of household appliances and their components. Approximately 55% of masterbatches are used for conventional polyolefins. PVC consumes about 20%, while styrene-based resins such as PS, ABS, SAN and their blends account for some 10%. Engineering resins are responsible for about 6%; other resins such as high-tech materials consume roughly 9%. Some 50% of masterbatches are consumed by injection molding, about 20% by extrusion, and approximately 15% each by blow molding and other processing methods. The current state of affairs In terms of the production, the plastics sector has been undergoing a process of consolidation worldwide for some time now. At the same time, the remaining companies are attempting to reduce their product range to a few standardized resins that can be produced in volume. Only specialty suppliers and compounders are in a position today to supply smaller quantities of products to satisfy special requirements. The above mentioned consolidation process is also being accompanied by a movement toward concentration on the processor side. The previously medium-sized plastics processors that were typical are in the process of becoming larger companies that, like their customers, operate globally. The medium-sized company will, in the future, more likely be the exception than the rule. Smaller processors will survive only if they can find niches for themselves that require a higher level of technical know-how and processing capability in terms of machinery and materials. Masterbatch suppliers must already confront these processes today: be it color tones that must be available around the world, be it a consolidation process affecting the rest of the industry as a result of economic pressures that impact both the company and the range of available products. Moreover, it will become increasingly important for the masterbatch industry to perform tasks that in the recent past were still the responsibility of the resin suppliers. This often means occupying those open areas at plastics processors that are no longer handled by the resin suppliers because of the "concentration on the core business". Responsibilities here range from design development through support during the release process for a material to feasibility studies, i.e. to answering the question as to whether a particular material is suitable for a specific application. Consequently, the masterbatch supplier is increasingly confronted with the task of also fulfilling the role of material qualifier for its customer. According to estimates by market mavens, the following structures have crystallized on the side of the colorant and additive concentrate suppliers since the start of the new millennium: The internationalists: This category includes first and foremost suppliers such as Cabot Plastics International and Ampacet that offer primarily standard products (black and white batches, additives and colorants) in large volumes. For the above mentioned commodities, orders are issued largely on the base of price. On the other hand, there are also suppliers who offer a wide range of specialties but can, if necessary, provide larger volumes as well. In terms of products and processes, these suppliers focus above all on fiber, packaging, blow molding, injection molding and extrusion. Companies that target these market segments include, among others, PolyOne as well as Clariant Masterbatches. This group of suppliers obtains its orders largely as the result of a specific support or other service as well as its innovation capabilities; material price is only oAdidas FalconThe modern masterbatch suppliers of tomorrowMichael Thiessenhusen

Source: Release Date:2008-07-17 1369

The market for colorant and additive concentrates (masterbatches) continues to grow. About 55% of the coloring aids are black (24%) and white batches (31%), with other colors accounting for about 25%. The most important fields of application are found in the automotive industry, in the packaging sector as well as in the production of household appliances and their components. Approximately 55% of masterbatches are used for conventional polyolefins. PVC consumes about 20%, while styrene-based resins such as PS, ABS, SAN and their blends account for some 10%. Engineering resins are responsible for about 6%; other resins such as high-tech materials consume roughly 9%. Some 50% of masterbatches are consumed by injection molding, about 20% by extrusion, and approximately 15% each by blow molding and other processing methods. The current state of affairs In terms of the production, the plastics sector has been undergoing a process of consolidation worldwide for some time now. At the same time, the remaining companies are attempting to reduce their product range to a few standardized resins that can be produced in volume. Only specialty suppliers and compounders are in a position today to supply smaller quantities of products to satisfy special requirements. The above mentioned consolidation process is also being accompanied by a movement toward concentration on the processor side. The previously medium-sized plastics processors that were typical are in the process of becoming larger companies that, like their customers, operate globally. The medium-sized company will, in the future, more likely be the exception than the rule. Smaller processors will survive only if they can find niches for themselves that require a higher level of technical know-how and processing capability in terms of machinery and materials. Masterbatch suppliers must already confront these processes today: be it color tones that must be available around the world, be it a consolidation process affecting the rest of the industry as a result of economic pressures that impact both the company and the range of available products. Moreover, it will become increasingly important for the masterbatch industry to perform tasks that in the recent past were still the responsibility of the resin suppliers. This often means occupying those open areas at plastics processors that are no longer handled by the resin suppliers because of the "concentration on the core business". Responsibilities here range from design development through support during the release process for a material to feasibility studies, i.e. to answering the question as to whether a particular material is suitable for a specific application. Consequently, the masterbatch supplier is increasingly confronted with the task of also fulfilling the role of material qualifier for its customer. According to estimates by market mavens, the following structures have crystallized on the side of the colorant and additive concentrate suppliers since the start of the new millennium: The internationalists: This category includes first and foremost suppliers such as Cabot Plastics International and Ampacet that offer primarily standard products (black and white batches, additives and colorants) in large volumes. For the above mentioned commodities, orders are issued largely on the base of price. On the other hand, there are also suppliers who offer a wide range of specialties but can, if necessary, provide larger volumes as well. In terms of products and processes, these suppliers focus above all on fiber, packaging, blow molding, injection molding and extrusion. Companies that target these market segments include, among others, PolyOne as well as Clariant Masterbatches. This group of suppliers obtains its orders largely as the result of a specific support or other service as well as its innovation capabilities; material price is only oAdidas Falcon

The market for colorant and additive concentrates (masterbatches) continues to grow. About 55% of the coloring aids are black (24%) and white batches (31%), with other colors accounting for about 25%. The most important fields of application are found in the automotive industry, in the packaging sector as well as in the production of household appliances and their components. Approximately 55% of masterbatches are used for conventional polyolefins. PVC consumes about 20%, while styrene-based resins such as PS, ABS, SAN and their blends account for some 10%. Engineering resins are responsible for about 6%; other resins such as high-tech materials consume roughly 9%. Some 50% of masterbatches are consumed by injection molding, about 20% by extrusion, and approximately 15% each by blow molding and other processing methods. The current state of affairs In terms of the production, the plastics sector has been undergoing a process of consolidation worldwide for some time now. At the same time, the remaining companies are attempting to reduce their product range to a few standardized resins that can be produced in volume. Only specialty suppliers and compounders are in a position today to supply smaller quantities of products to satisfy special requirements. The above mentioned consolidation process is also being accompanied by a movement toward concentration on the processor side. The previously medium-sized plastics processors that were typical are in the process of becoming larger companies that, like their customers, operate globally. The medium-sized company will, in the future, more likely be the exception than the rule. Smaller processors will survive only if they can find niches for themselves that require a higher level of technical know-how and processing capability in terms of machinery and materials. Masterbatch suppliers must already confront these processes today: be it color tones that must be available around the world, be it a consolidation process affecting the rest of the industry as a result of economic pressures that impact both the company and the range of available products. Moreover, it will become increasingly important for the masterbatch industry to perform tasks that in the recent past were still the responsibility of the resin suppliers. This often means occupying those open areas at plastics processors that are no longer handled by the resin suppliers because of the "concentration on the core business". Responsibilities here range from design development through support during the release process for a material to feasibility studies, i.e. to answering the question as to whether a particular material is suitable for a specific application. Consequently, the masterbatch supplier is increasingly confronted with the task of also fulfilling the role of material qualifier for its customer. According to estimates by market mavens, the following structures have crystallized on the side of the colorant and additive concentrate suppliers since the start of the new millennium: The internationalists: This category includes first and foremost suppliers such as Cabot Plastics International and Ampacet that offer primarily standard products (black and white batches, additives and colorants) in large volumes. For the above mentioned commodities, orders are issued largely on the base of price. On the other hand, there are also suppliers who offer a wide range of specialties but can, if necessary, provide larger volumes as well. In terms of products and processes, these suppliers focus above all on fiber, packaging, blow molding, injection molding and extrusion. Companies that target these market segments include, among others, PolyOne as well as Clariant Masterbatches. This group of suppliers obtains its orders largely as the result of a specific support or other service as well as its innovation capabilities; material price is only oAdidas Falcon

You May Like

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login