Medical-grade plastic and specialty chemical manufacturers are unveiling innovative healthcare products that promise flexibility combined with strength, upgraded radio frequency identification (RFID)-enabled tags for small to medium containers and brilliant coloured latex gloves that meet US/EU safety standards.

Teknor Apex Company recently launched its new series of Medalist® compounds that are flexible over a wide range of temperatures with weldable and heat-sealable properties. Avery Dennison introduced its latest RFID inlay label products to help healthcare companies in their inventory and supply management needs. As a leading supplier of colorants dedicated to latex applications, Clariant offers cost effective pigment solutions that meet US and Europe compliance regulations.

Elastic and durable tubing

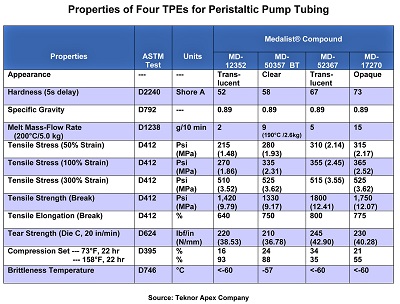

The new series of Medalist medical-grade thermoplastic elastomers (TPEs) compounds for peristaltic pump tubing from Teknor Apex provides not only elasticity over a broad temperature range, but also enables the tubing to withstand the stresses of pump action over time. The Teknor Apex TPE is weldable and heat-sealable unlike silicone. Targeted for the biotech and pharmaceutical industries for medical infusion systems and dialysis machines, Medalist comes in clear, translucent and opaque grades of tubing.

In terms of spallation, Medalist TPEs exhibit the lower levels compared to other TPEs. Spallation is the shedding of particles in tubing’s inner surface. This is caused by the wear and tear of repeated compression and release during pump operation. Teknor Apex TPEs are augmented by elasticity that enables the tubing to match the rapid pump action. This, combined with longer durability, ultimately allows it to retain its original shape and survive prolonged exposure to regular pump series action.

Apart from exhibiting low level of extractables, Medalist compounds are versatile and compatible with a host of chemicals. The specialty elastomer is made sterile either by e-beam, gamma or ethylene oxide. For biopharmaceutical applications that require extreme low temperature requirements, the company offers specialty grades to address these prerequisites.

Medalist’s MD-12352 and MD-52367 lines are both translucent compounds with low melt mass-flow rates of 2 and 5 respectively (200°C/5.0kg). MD-52367, a clear TPE, exhibited a 9 rating (190°C/2.6 kg). The opaque MD17270 has the highest rating at 9. Melt Mass-Flow Rate is a one number indication of the viscosity of a polymer in the melt phase. It is defined as the mass of polymer in grams flowing per 10 minutes through a capillary of specific diameter and length by a pressure applied via a range of standard weights at specified temperature.

The MD-52367 exhibits the best tensile elongation break at 800 with a tensile strength at 1800 ksi (elongation at break – 12.4%). Additional feature of MD-52367 is 245 tear strength (Die C, 20in/min). It registers at <-60 for brittleness temperature, which is also true for the MD-12352 and MD-17270 series.

Medalist compounds are produced in Teknor Apex ISO-13485 facilities in the USA and Singapore. The new materials are certified to ISO 10993-5 standards for biocompatibility and REACH SVHC compliant. They are made with FDA listed ingredients and free of DEHP and other phthalates, BPA, and latex. Standard grades are ADM-free.

Advanced UHF RFID tags

Tracking inventory, brand security and counterfeit deterrence are some of the current major concerns in the healthcare and medical companies. Avery Dennison targets pharmaceutical and healthcare industries in the search of the latest RFID solutions with its latest line in ultra-high tech frequency (UHF) RFID inlay label products. This latest line of UHF RFID tags is ideal for tagging small to medium-sized bottles. The company produces globally tuned inlays that can achieve up to a 1.7-meter read distance when applied to liquid-filled glass or plastic bottles. This makes it ideal for tagging glass vials and other small to medium-sized medical packages.

Avery Dennison’s AD-810r6 exhibits excellent performance on glass and plastic materials with an 18mm diameter footprint. The AD-810r6 inlay is equipped with the Impinj Monza R6 integrated circuit. The inlay has a tag chip that provides 96-bit EPC memory and features AutoTune RF tuning. The 16mm round antenna is cleanly cut onto an opaque white PET carrier.

Avery Dennison targets pharmaceutical and healthcare industries with its latest RFID solutions

AD-850m4QT’s antenna size measures just 10.3mm in diameter, the smallest offered in Avery Dennison’s Gen2 RAIN compliant UHF inlay series. This tiny tag is suitable for applications requiring a smaller form design recommended for reading tagged items in near-field. The tag has a simple, circular loop design that features the Impinj Monza 4QT integrated circuit. This can achieve up to a 1-metre read distance in FCC (920-928 MHz) when applied to liquid filled vials made of either plastic or glass. In addition, the chip enables users to maintain a public and private data profile for confidential data storage and consumer privacy, coupled with a large, 512-bit user memory. Both inlays deliver optimal delivery lead times and are available in two formats - dry inlay and wet inlay.

Colourful solutions for gloves

As a leading supplier of colourants for latex applications, Clariant offers outstanding colourant and pigment formulations to its customers in the global glove market. The company aims to meet increasing market demand for quality glove products that meet specific quality assurance standards. Clariant understands the stronger emphasis on satisfying relevant regulatory requirements for glove products.

Clairant’s Cosmenyl series complies with requirements imposed by the European Commission for cosmetic colourants in Cosmetic Directive 76/768/EEC on cosmetic products. Together with selected Flexonyl and Colanyl 500 colourants, they meet the purity requirements for heavy metal trace impurities and the content of primary aromatic amines as covered by EU standard EN 71-9, as well as the Community of Europe Resolution AP (89)1.

The company also produces selected colourants that meet specific US regulatory requirements. These include the Colanyl and Cosmenyl ranges of individual basic pigments for special pigment preparations. The two colourants comply with US regulation for rubber articles intended for repeated use in food contact applications FDA 21CFR 178.3297. The highly concentrated, APEO-free aqueous pigment preparations are readily mixable in water-based systems for excellent colour yield.

Aside from safety compliance, Clariant's wide range of colourants and pigments are known to offer excellent versatile functionality. Colanyl 500, a range of aqueous, binder-free pigment preparations, is specially developed for modern low VOC applications by manufacturing without alkyl phenol ethoxylated (APEO) additives. Colanyl 500 products are also based on non-ionic and/or anionic wetting and dispersing agents. Therefore, processing of Colanyl 500 preparations is facilitated by their excellent stability to settling and skinning.

Clairant’s Cosmenyl series complies with Cosmetic Directive 76/768/EEC on cosmetic products.

The "regional version" of Colanyl, CC Fine Paste and FlexonylWF colourants provides higher cost-efficiency for local latex clients. Without product attributes designed to satisfy particular compliance requirements, these products are best suited for cost-sensitive applications in which no specific regulations apply. These aqueous pigment preparations are manufactured without ethoxylated alkyl phenols (APEO) and can be added directly into any latex systems for excellent colour yield.

The company’s customers in the region will also be able to benefit from outstanding support and technical service available from Clariant’s Pigments business unit in the South East Asia and Pacific region. Clariant’s Pacific Technical Application Centre has been upgraded in capacity to allow the business unit to provide comprehensive and further customisable technical services to customers from multiple industries in the region, such as coatings, paints, printing, plastics and other specialised applications.

Air Max 95 Jacquard Flyknit

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login