A NEW desalination technique is able to remove salt from water using less energy than previous methods.

“Globally, there is reduced access to fresh water,” said Bruce Logan, Evan Pugh University Professor in Engineering and the Stan and Flora Kappe Professor of Environmental Engineering. “More and more, the waters that are being used are impaired, either due to salt or other contaminants, so we are seeing an increasing need to rely on less optimal water sources.”

Logan, and colleagues Christopher Gorski, assistant professor of environmental engineering, and Taeyoung Kim, post-doctoral scholar in environmental engineering developed the desalination method called battery electrode deionization (BDI). This new solution improves upon standard capacitive deionization (CDI) techniques by eliminating the regeneration stage and lowering the voltage required to complete the process.

Standard CDI techniques desalinate water by separating the water’s ions. A typical CDI cell consists of two electrodes attached on opposite sides of a flow channel. The electrodes capture the salt ions through electrical exchanges that occur when an electrical current is applied to the cell. The cell is then regenerated by releasing the salt ions in a second cycle by alternating the direction of the applied electrical current. Since CDI does not require membranes and has lower energy requirements than other popular methods, it is becoming a competitive technology for removing salt from water. The problem with CDI systems is that they are limited by low salt adsorption when using the typically applied 1.2 volts. Increasing the applied voltage does improve the salt adsorption, but it also increases the potential for unintended side reactions that waste energy and can create permanent electrode corrosion.

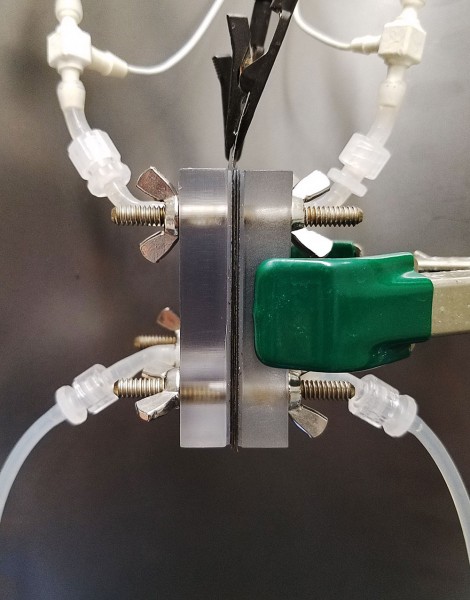

In the team’s newly developed BDI system, a custom-built flow cell utilizes two channels. The channels are separated by a membrane and two identical battery electrodes are secured at each end.

To test the cell’s effectiveness, the team fed each channel with a salty solution at a specified flow rate while applying a constant electrical current to the cell. Several current densities were used, depending on the number of membrane stacks. The researchers then reversed the cell voltage flow when it reached a low of −0.6 volts or a high of +0.6 volts.

The team discovered that the BDI system effectively removed the salt at levels consistent with CDI, while using only an applied voltage of 0.6 volts. Furthermore, the low voltage required and materials used helped prevent unwanted side reactions, achieved greater desalination abilities and consumed less energy than traditional CDI.

Since the team created simultaneous production of desalinated and concentrated water in two channels, it also circumvented the two-cycle approach, so the system no longer needs to go through the regeneration stage. Additionally, they found that stacking additional membranes between electrodes reduced energy consumption even further.

A feed solution contained in a reservoir was separately fed to the two inlets of the flow cell using pumps, one desalinated and the other concentrated. This is achieved by applying electrical current to the flow cell through wires using a power source (not shown in this photo). The conductivity of the discharge was then measured using flow conductivity meters located at each outlet, which were monitored by computer. (Photo credit: Taeyoung Kim)

“Other people have talked about capturing energy from the second CDI cycle, but it's really hard to do, and, therefore, it's impractical,” Logan said. “Our system avoids that second regeneration step by just switching the captured flow by alternating the direction of the applied electrical current. That makes it very easy to operate, and it uses very little energy.”

Although the current configuration is not suited to desalinate extremely salty water such as seawater, the results show that the BDI technique could be effective as a low energy method for brackish, or slightly salty, water, such as groundwater, or for desalinating water before it enters treatment plants.

“There is nothing that inherently prevents its use with seawater, it's just that as water gets saltier and saltier, there are other issues that we have to contend with, such as increased energy consumption and membrane fouling, that may reduce its utility relative to other approaches,” Logan said.

The researchers now plan to work on scaling up and improving the stability of the system.

“This is an innovative technology,” Logan said. “This is not something that is out there and commercialized. It's something that is right at the cutting-edge of new ways to get salt out of water.”

This research was published in Environmental Science & Technology Letters in September. Funding was provided by the National Science Foundation, King Abdullah University of Science and Technology and Penn State University.

Nike