As a result, Auto-Form Engineering has unveiled its latest software version Auto-Form Plus R7. This enables users to reach the next level of process simulation through a new set of powerful enhancements and functionalities.

With this, users benefit from higher flexibility and efficiency in process set-up and final validation for all forming processes in general and in particular for progressive dies and hot forming.

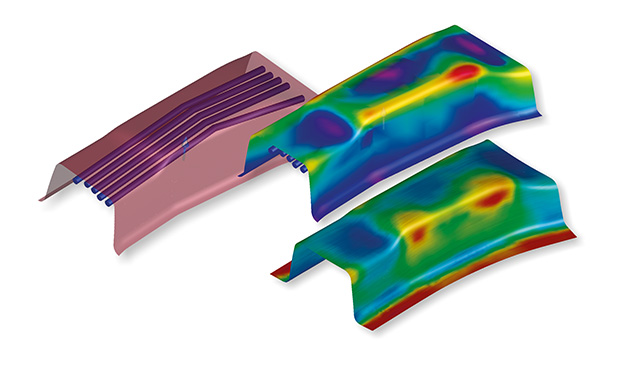

Auto-Form Plus R7 is aimed at bringing advances in process modelling for hot forming as this release allows users to take cooling channels into account. Cooling channels can now be easily modelled with 3D curves and their corresponding diameters. Different cooling channel layouts lead to different temperature distributions on the tool surfaces. Hot spots on the tool surface can be easily detected and controlled depending on the selected layout of the cooling channels.

According to the company, one of the major highlights of Auto-Form Plus R7 is the improved planning and simulation of progressive dies. In particular, Auto-Form Plus R7 supports the following use cases: import of CAD-designed tool geometry for the final process validation, part import for the planning stage and part import for full process engineering, which includes die face generation and simulation. These use cases are supported by new functionalities which enable users to efficiently plan and simulate progressive dies.

In addition, Auto-Form Plus R7 enables users to benefit from Auto-Form-Sigmaplus capabilities as all Sigma pre and post processing functionalities are now integrated within Auto-Form-ProcessExplorerplus. Auto-Form Plus R7 software users can now take advantage of Sigma applications – Systematic Process Improvement and Process Robustness. As a result, users can ensure a highly efficient engineering process and robust part production while meeting desired quality requirements.

Dr. Markus Thomma, Corporate Marketing Director of Auto-Form Engineering, stated: “We have once again unveiled a new software release which is testimony of our latest development endeavors. We invite you to join us at our roll-out events which are currently being held all over the world. At these events, we will give you insights into new enhancements and functionalities which were developed to better assist you when using our software.”

Air Jordan VII 7 Retro