MINERAL oil residues in spreads, chocolates or muesli? Food safety lapses are occurring with increasing frequency, and this includes contamination by lubricants in production machinery or packaging printed with mineral oil. BOGE Kompressoren offers a wide range of oil-free compressed air systems that are designed with customised preparation systems to help food manufacturers achieve maximum safety and avoid expensive product recalls.

“All technologies that come into contact with foods have to be oil-free, including compressed air. Whether it is conveying flour, filling wine, sorting salad leaves or cleaning packaging, oil-free compressed air of Class 0 is an absolute precondition to ensure safe foods for consumers,” says Nalin Amunugama, General Manager, BOGE KOMPRESSOREN Asia Pacific.

Further, many compressed air system suppliers overlook the significance of the quality of the intake air. Specifically, oil-free Class 0 compressed air is only guaranteed if the intake air also meets the conditions of Class 0. Currently, compressors that fall into this category are those that demonstrate a lower residual content of oil in oil-free generated compressed air than compressors in Class 1.

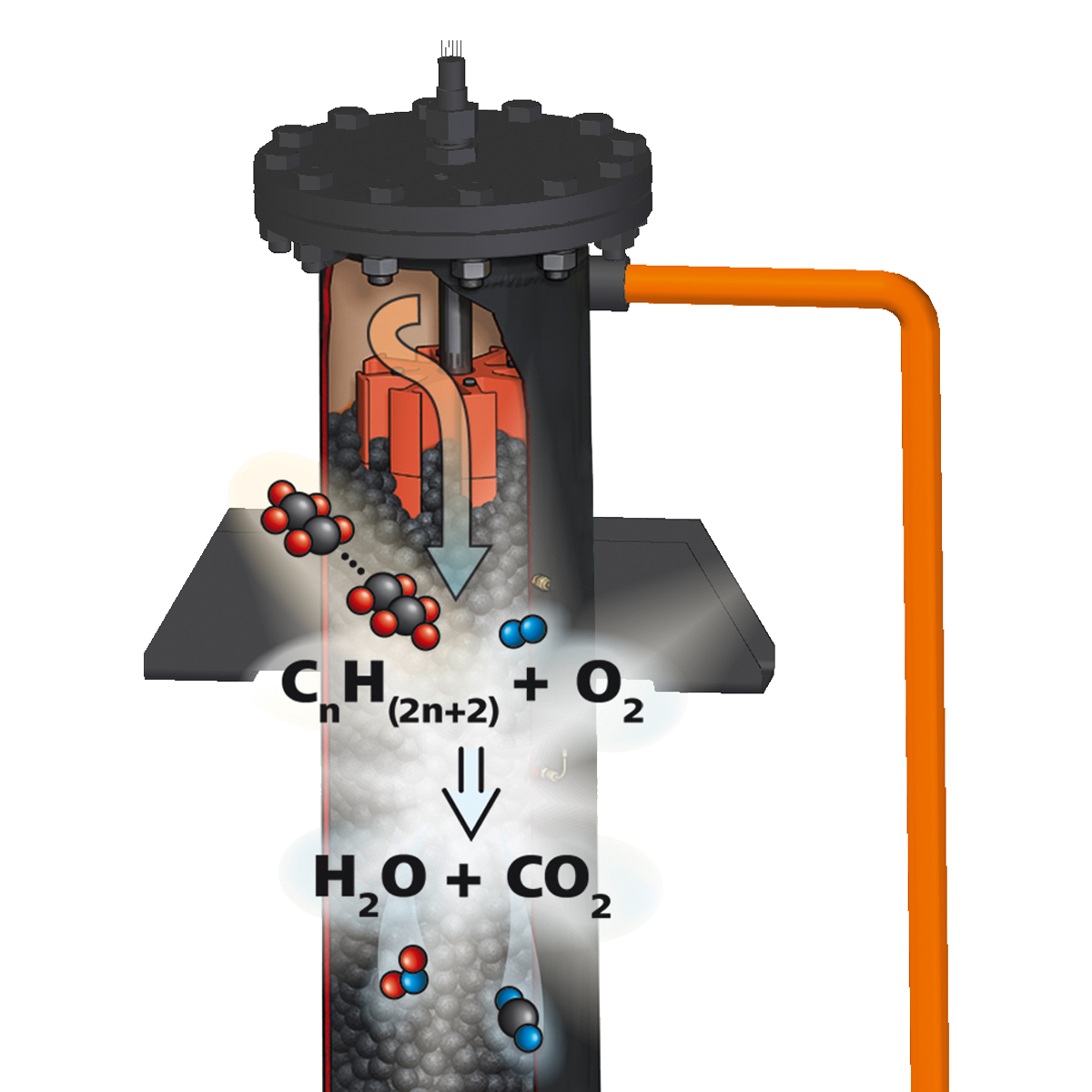

The BOGE BLUEKAT Series produces Class 0 quality oil-free compressed air, while eliminating expensive condensate disposal – the ideal solution for oil-free compressed air, especially for sensitive industrial applications

The BOGE BLUEKAT models have an integrated converter that reliably oxidises the oil in the compressed air to carbon dioxide and water

BOGE makes a finer distinction: although it offers completely oil-free systems such as the HST, PO and Scroll series, which can generate high-quality compressed air in Class 0, it makes sure to emphasise that this is dependent on the quality of intake air. Only the BOGE BLUEKAT range supplies oil-free compressed air of Class 0 under all conditions – these compressors operate with a catalytic converter that changes hydrocarbons into water and carbon dioxide in a chemical reaction. Unlike conventional filter systems like activated carbon, the air quality is constant. The catalyst works independently of the temperature and humidity of the reprocessed air.

Engineered to efficiently generate large quantities of oil-free air (in base load or intermittent mode), BOGE’s oil-free screw compressors can be optimally adapted to every site condition, to ultimately play an important role in critical applications such as in the food industry.

“With a reliable supply of oil-free air, users can also benefit from less expensive downstream air treatment, minimising total costs and energy consumption,” as Mr Nalin points out.

Nike SB Hyperfeel Koston 3

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login