"The booth is designated as the first onestop centre to offer a variety of sheet metal processing techniques, as well as wholeplant solutions. Yung Hua and TOA DR are experienced in supplying mid- to large steel company’s coil centres, as well as precision thin sheet or plate. Yung Hua has sold over 380 production lines worldwide in the past 73 years, and TOA DR has sold around 200 production lines since 1972."

Metal slitting lines

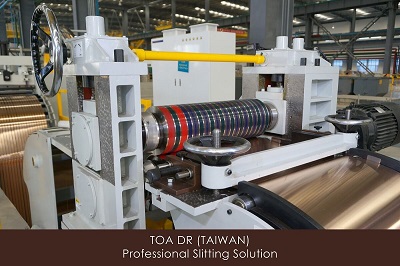

TOA DR Enterprise Co., Ltd. was established in 1972. The company specialises in the manufacturing of metal slitting machines and whole plant sales in Taiwan. It holds several product line patents and can customise lines for customers. With a strong team of designers (one third of the company's employees), TOA DR has facilitated several machine systems including a hydraulic slitting knife-locking system and friction recoil system. Its main aim is to increase processing efficiency as well as quality.

"A Chinese mid-sized steel coil centre company with 100,000 tons of production capacity per year intended to upgrade its factory facility to tap into higher-end niche

fields for higher profits. We cooperated with the company to resolve problems with low precision quality and utilisation rates. The main task was to improve its quality of production when producing higher sensitivity sheet metals such as stainless steel and galvanized sheet metal," explained TOA DR. "The solution was to build up its facilities with several production lines, all of which were tested before delivery, which increased by 40% its overall yield rate."

The lines supplied were two cut-to-length (rotary shear) lines (T: 0.3-2.3mm, W: 1250mm with 6HI leveller and T: 0.3-2.0mm, W: 800mm with 6HI leveller), a slitting line (T: 0.5-4.5mm, W:1550mm with tension roller) and a minislitting line (T: 0.1-2.0mm, W: 600mm).

Slitting and levelling

Yung Hua Machine Works Co., Ltd. was established in 1945, and has long experience in designing plant facilities and slitting lines for high-profile global steel factories, including Red Bud from the U.S. and Token from Japan. In a project with Bangkok Eastern Coil Centre, a company operating as a subsidiary of Nippon Steel Trading (Thailand) Co., Ltd, Yung Hua built a high-tension heavy gauge slitting and levelling line with cross bow and camber regulating functions. The line will help the client to achieve its production target of high-tension plates (9mm*500mm*12000mm) while decreasing 80% of its plate deficiencies, according to Yung Hua.

Another company, Guangzhou Ribao Steel Coil Centre, wished to speed up the cleaning process of its leveller workroller to avoid contamination from different materials. But, with traditional levellers, users need to disassemble the universal joint first, and then clean the work roller (which takes 4-8 hours in total).

"We created a solution called Work Roller Quickly Take Out System. This system could bypass the need to disassemble the universal joint, and the entire cleaning process is now under two hours (increasing efficiency by a factor of 2-4)."

Meet both companies at EuroBLECH on stand B123 (Hall 27) or access www.yunghua.com.tw/ and www.slitterline.com.