Steering a global business through economic and technology landscape is challenging at the best of times. Looking ahead to 2019, key planning assumptions are changing fast. Localisation pressures and digital disruption all factor into an increasingly challenging environment for companies of all sizes.

Digital is changing just about everything today, and companies must evolve to the needs stemming from that change. In particular, customers want to engage in a completely different way than ever before. They want to engage on a highly sophisticated platform, which allows them to learn and buy what they need to make their businesses profitable.

Customers are faced with wanting to get the best machine available but realise it’s a lot of work. Here at International Metalworking News for Asia, we would like to help our readers by offering them with different solutions. End users look for machine tool builders for knowledge and we are here to provide them with views and initiatives from three leading machine tool builders.

Armin Stolzer

Managing Partner

KASTO Maschinenbau GmbH & Co. KG

The currently favourable situation in widespread parts of the global economy and in the metalworking sector is leading to many companies increasing their production output. However, for the most part, additional capacity is usually necessary to enable the larger number of orders to be processed on time. More and more users are therefore deciding to automate processes, including in the sawing and storage technology sector. This offers considerable potential and, at the same time, the necessary flexibility to be able to respond to changing requirements.

This is where we can provide users with optimum support. We help companies to achieve significant improvements in production efficiency while at the same time reducing their costs – two outcomes which in today’s economically challenging climate are in especially great demand.

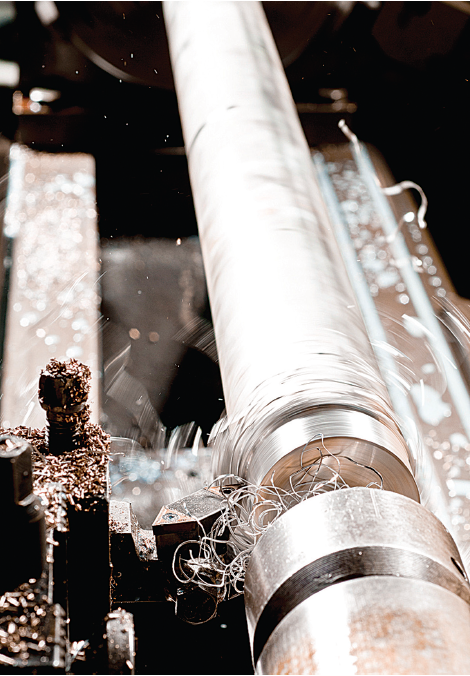

Our sawing machines and storage systems can be easily integrated into a digitalised and automated material flow. We also offer combined sawing and storage systems in which all the storage, handling, sawing, marking, palletising and bundling processes are performed fully automatically with the help of industrial robots – from putting the raw material into store through to the picking of the cut parts.

In order for all steps in an automated production process to mesh smoothly, the right interfaces are required. This is why KASTO customers get everything from a single source. At the software level we also have innovative solutions that are perfectly adapted to industry needs, for example in the form of our well-designed machine control systems and KASTOlogic Warehouse Management System. Our warehouse management software automatically controls all the processes between goods receiving and dispatch, including the connected sawing machines. With our customised complete systems, metal-processing companies can fully utilise the potential of their production and logistics facilities.

Israel Gonzalez

Asia Pacific Regional Director

Hypertherm

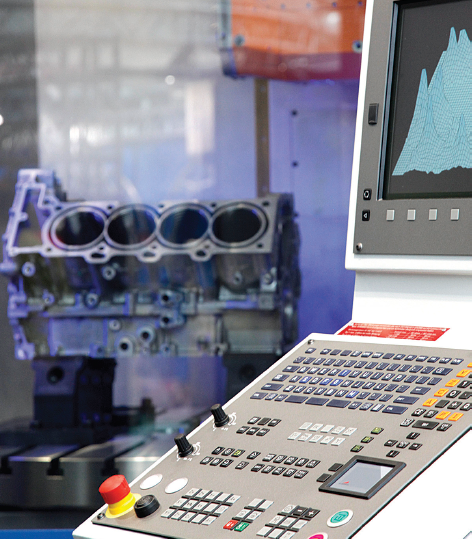

Today’s markets are characterised by complexity, ambiguity, and uncertainty. In a similar way, fluctuating oil and raw material prices can have a big impact on the profitability equation for the manufacturers in the years to come. Transformations to the manufacturing sector are also further propelled by the rapid evolution of technology. To achieve growth targets in the coming year, manufacturers will increasingly see the need to prioritise investments in technology that will enable their business to improve agility, which includes increasing productivity, speed, and responsiveness, and connectivity.

Hypertherm’s focus has always been on helping our customers reduce operating costs and improve cutting performance, so that they can enhance their profitability. Besides a wide range of solutions for automation and portability, we also offer unmatched cut quality and precision through our latest X-definition™ class plasma system, which is another example of how we are able to address the changes ahead for manufacturers. Our continued investment in research and development is part of our efforts to bring more breakthrough technologies to the market. In addition, we are also committed to working closely with our customers to learn more about their user experience and possible pain points. With this understanding, we are better positioned to develop application-specific solutions to address the issues they face. Our innovations are designed to support manufacturers in improving the agility of their businesses, and we look forward to changing people’s perceptions of plasma with our advanced cutting innovations.

Markus Lindemann

Head of Laser Technology Asia Pacific

TRUMPF Pte Ltd

We just started our trip for 4.0. Year 2019 will lead us more to this direction. More people will be more aware and more solutions will be coming out. This is one of the most important topics for the industrial manufacturing. Of course new technologies coming like additive manufacturing, and new lasers.

For TRUMPF laser, it’s a journey for the past 30 years. Every year something new is coming up and we’re just guided by our partners to develop the right lasers for different industries. We can’t develop a laser source by ourselves, we always develop it for our customers. The customers’ telling us what they need, the more precise we can develop for certain application. This is what TRUMPF is so successful – we do this by our key customers for many years and we always bring them to a level where no competitor can do because they use the latest technology. Speed is also a very important topic at the market for additive manufacturing and also for any other kind of production, and with new laser technology you definitively have a competitive advantage for the future.

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login