By MIFLORA M. GATCHALIAN, PhD. CEO, Quality Partners Company, Ltd.

Introduction

INNOVATION is defined as a unique creative idea that adds value to the organisation’s external customers and to the stakeholders since it is expected to generate profit (Gatchalian, 2018(a); Harrington, J. 2015). Idea creation generally stems from the realisation of a need to fullfil perceived customer requirements. Partcularly for the food industry, constant innovation is imperative if one is to remain competitive in the marketplace (Winger and Wall, 2006). For this reason, several approaches to food product innovation had been proposed by various sectors in the world.

Among the many pathways to innovation recommended for productive purposes, the problem-solving approach is deemed most useful and practical (Menrad, 2007). Considering the steps utilised in the innovation process, one that leads fastest to eventual product development and early market launch, make use of sensory evaluation during the stages of problem-solving (Gatchalian and Brannan, 2011). Activities in food product innovation leading to development and eventual launching in the market, utilise certain types of scientific problem-solving approaches to ensure effectiveness and efficiency of the process.

Approaches to food product innovation

By its definition, the ultimate result of innovation would be the assurance that there are potential customers in the marketplace willing to purchase the new product. It is assumed that creative ideas leading to innovation were generated only after learning the needs and requirements of potential customers. Thus, idea generators are expected to be active participants during discussions of customer needs and requirements.

Many approaches to innovation had been recommended by authorities in various sectors of the world. Among them are those who presented the following directions: (A) Steps in the innovation process; (B) Stages in product development; and (C) Problem solving tools. All the three utilise a scientific approach resulting to measurable outputs after undergoing a logical sequence of activities which are valid, repeatable, reproduceable and reliable, or the well-known characteristics of a scientific approach.

-

Steps in the innovation process include the following:

Step 1 Identify the consumer or market need

Step 2 Generate ideas focused on the need

Step 3 Select the best idea to meet the need

Step 4 Conduct product development activities

Step 5 Test the market and determine profitability

Consumer and/or market needs are identified in Step 1 from in-depth discussions among idea generators and the management representatives in the company. This process, generally known as brainstorming, is one of the major problem-solving tools used to elicit ideas from discussion participants. Once the need is clearly identified (Step 2), several candidate products become the focus of attention and this requires tools for proper selection of the topmost product candidates (Step 3) which could be recommended for development (Step 4). Finally, the newly developed product will be tested for their market performance (Step 5). Other tools useful for selection of the best idea to ensure meeting the consumer’s needs will be discussed in succeeding sections. However, the sequence should always start from knowledge of consumer needs leading to product selection for development and finally to market test and profitability determination.

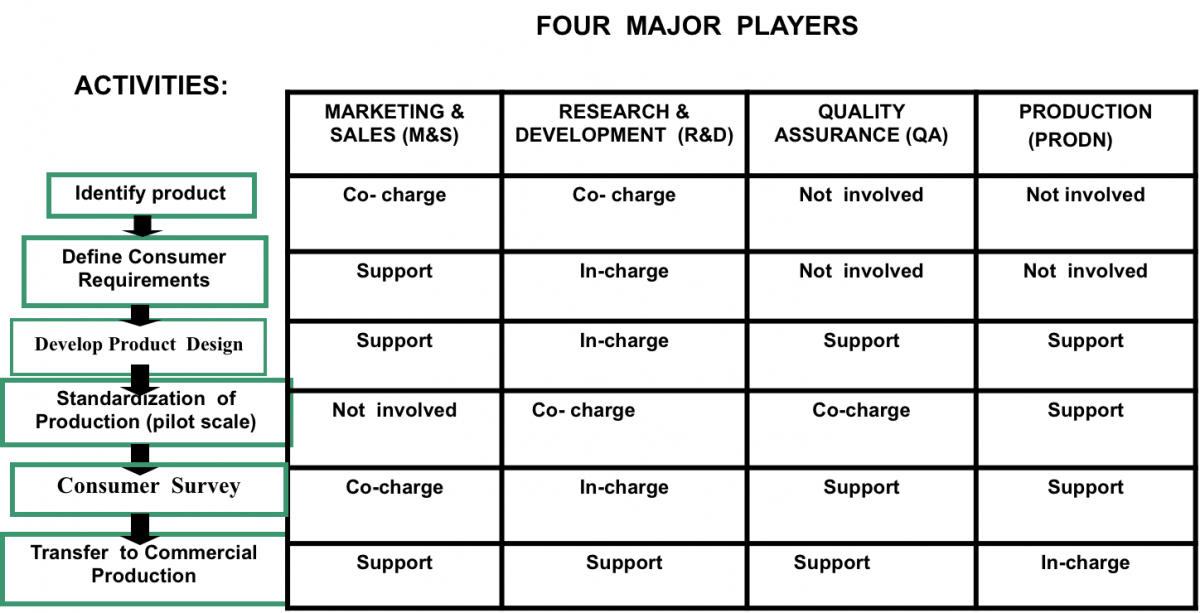

B. Stages in product development, a step in the innovation process (Step 4), is shown in Figure 1 where the role of the four major players within the manufacturing organisation are specified. In most food manufacturing companies, the four major players include those from: (1) Sales and Marketing (S&M); (2) Research and Development (R&D); (3) Quality Control (QC) and (4) Production as seen in Figure 1 (Gatchalian and Brannan, 2011). These players are generally considered as the idea generators of the company from whom innovation directions emanate. Thus, S&M people, known to be directly in contact with consumers, are expected to obtain information about their needs and requirements. Through S&M’s constant communication with R&D, ideas regarding new product development are generated. Each of the activities, in Figure 1, include the progressive steps in the innovation process (Steps 1- 3) starting with knowledge of consumer needs to product identification itself. Thus, Product Development starts with knowledge of product identity based on customer requirements as identified in the first three steps of the innovation process. At this stage, the four major players know the areas for which they are given the “charge” to handle and provide assurance of completion towards commercial production. In all these activities, scientific problem-solving approaches are utilised to ensure progress towards the succeeding steps at least cost in terms of time, money and effort.

Fig.1. Product development stages showing role of four major players

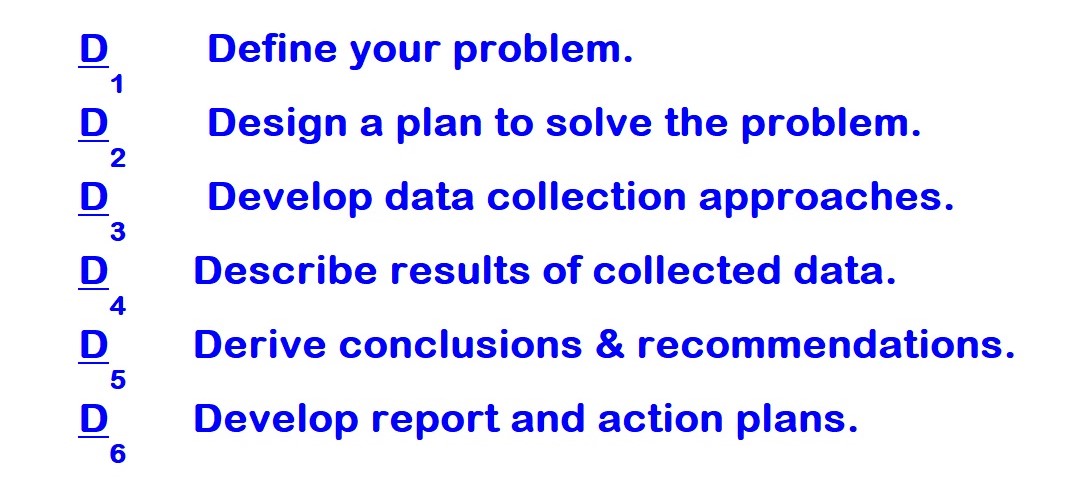

C. MMG’s 6Ds in problem-solving shows seven problem-solving tools utilised in the innovation process leading to eventual commercial production. This approach had been used as the framework of product development and improvement activities. Considering both the steps in the innovation process (A) and the stages of product development (B), this approach (C) had been found very useful in food product innovation (Gatchalian and Brannan, 2011) towards final market-launch.

The MMG’s 6 Ds of Problem-solving is shown in Figure 2 where “D1- Define your problem” is deemed as the most important step in Product Development (Figure 1) since this is the starting point in any problem-solving process in food product innovation. Once the problem is clearly defined, “D2- Design a plan to solve the problem” becomes easy to envision and develop. The seven (7) problem-solving approaches in food product innovation are embedded in MMG’s 6 Ds as follows:

Fig. 2. MMG’s (Miflora M. Gatchalian) 6Ds of Problem Solving

D1- Define your problem

Through the use of problem-solving tools like (1) Brainstorming, (2) Affinity Diagram, and (3) Checklist Screening, the problem of product identification is eventually clarified and properly defined.

Problem-solving 1 Brainstorming is a problem-solving approach whereby everyone in the Team is expected to share ideas regarding the problem presented to enable them to have a common understanding of the situation and eventually focus on a clear problem definition. Figure 3 is a graphic presentation of what “brainstorming” of people’s varied “brain-power” would entail. The approach encourages everyone in the Team to share their ideas about the situation presented regardless of the nature of their varying backgrounds. With good Team leadership, a decision on the choice of “product to be developed” is obtained and this, to a large extent, helps define the problem.

Fig. 3. People’s varied “brain-power” in “brainstorming” (Photo: Quality Partners Company Inc)

Problem-solving 2 Affinity Diagram encourages everyone in the Team (during brainstorming) to list down as many ideas regarding the topic at hand until a sufficient number of ideas are generated. The first set of outputs (listing of ideas) are classified into major groups of related ideas as shown in Figures 4a and 4b. Further brainstorming on the groups of ideas eventually narrows down the areas for selection until eventually a problem is fully defined. The graphic presentation of ideas allows the participants to clearly see each other’s idea contributions which can be grouped and re-grouped until a consensus, (when everyone agrees) is achieved. This should lead towards an agreement on the product identity which all members perceive as meeting the identified consumers’ need.

Fig. 4a. Affinity diagram, idea grouping

Fig4b Manual idea grouping

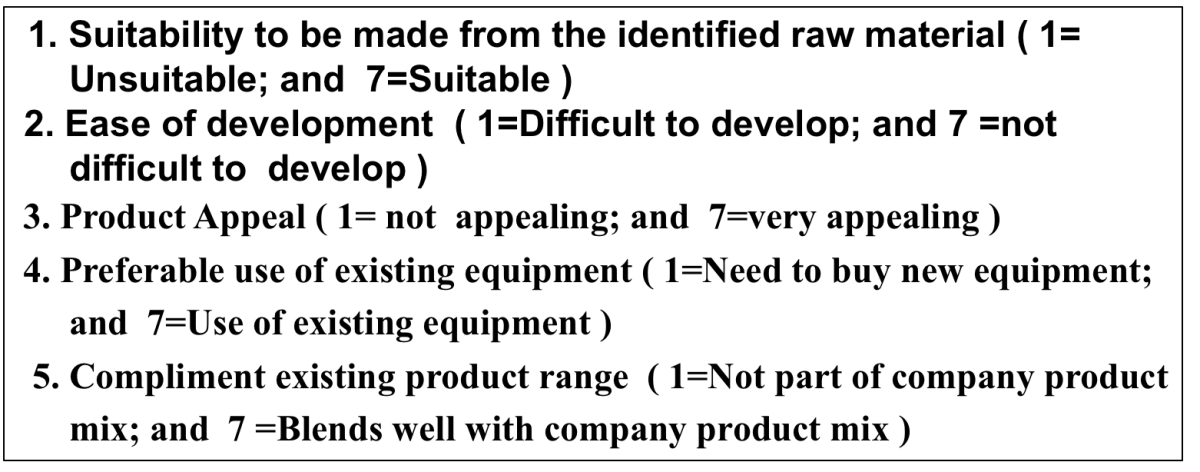

Problem-solving 3 – “Checklist Screening” reviews the ideas generated pertaining to the product identity and relates these to certain “Factors” of major concern existing in the manufacturing plant. Figure 5a presents the “Factors” associated with extent of their usefulness in product manufacture and these are assigned a score range of 1-7. This serves as a guide to the Innovation Team members in making their choice of a product for innovation. The product evaluated that obtains the highest total score or that meets their Standard Score could be the choice for product development and as such, defines the problem more clearly.

Fig. 5a. Factors for idea consideration and respective score range (1-7)

If another candidate product, analysed in a similar manner, obtains a total score of 145, it could be the one recommended for product development. Others use a standard total score to achieve, like 180, as basis for recommendation.

Fig. 5b. Checklist screening showing the total score (129)

D2 – Design a plan to solve the problem

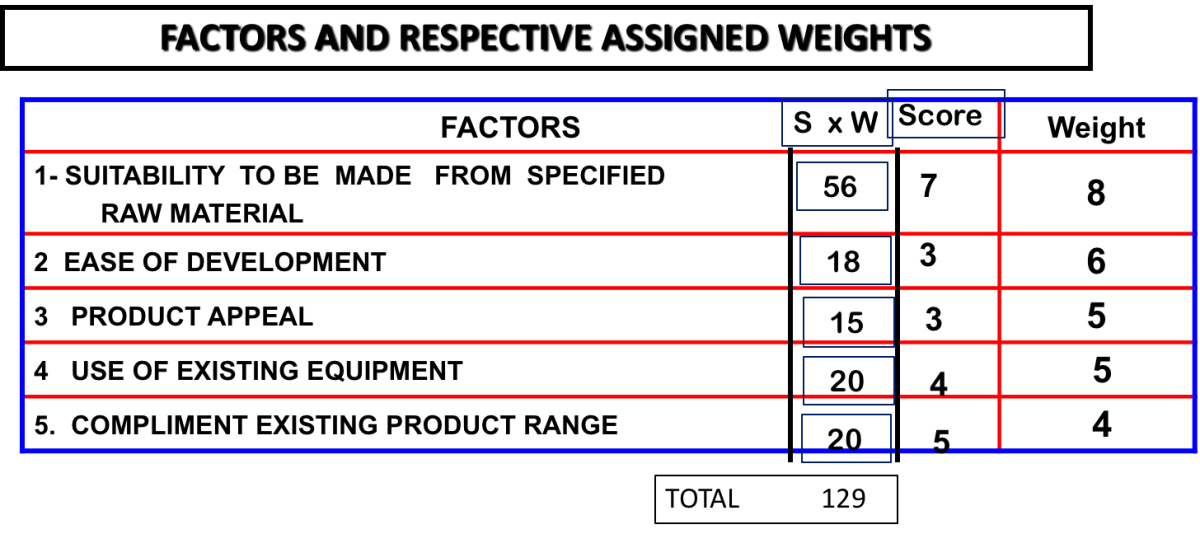

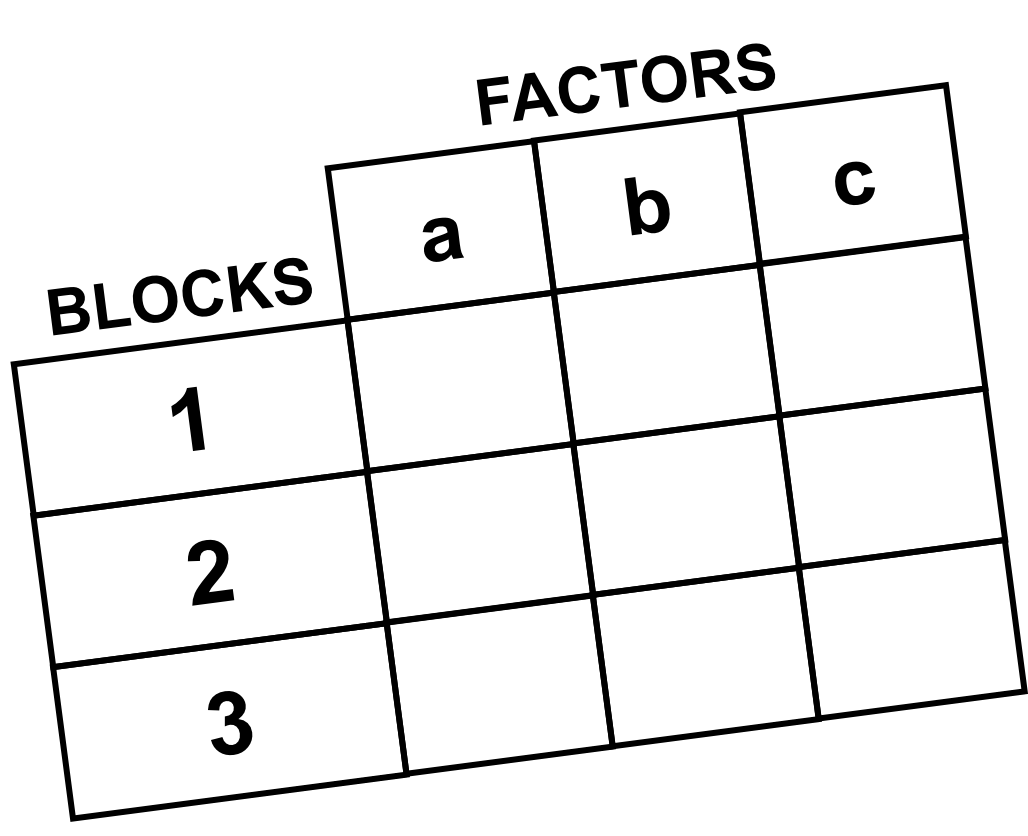

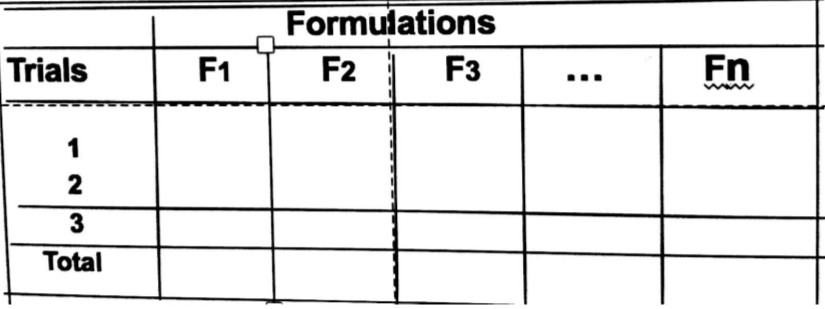

Once the problem is clearly defined and the product to be developed already identified, plans for the development process will be designed considering all the “Factors” associated with its proposed development. Designing a plan would require visualising several steps, some of which will utilise problem-solving tools and techniques to achieve desired results. Figure 1 (earlier presented), shows the stages in product development, after the food product needed by the consumers had been identified. A review of the defined problem (Figure 2 -D1) should lead to a better understanding of consumer requirements which, in the first place, were used as basis for product identification. In order to arrive at the desired food product, experimentation of various formulations will have to be done. Some experimenters develop as many as five or more formulations at a time and then narrow this down to two or three after a series of sensory evaluation tests. One example of a design often used in determination of best formulation for a new product is shown in Figure 6. In problem-solving this is labeled as the “design matrix” (Fig. 6a) while in design of experiments, this is known as the “complete block design” (Fig. 6b). Note in Fig. 6b that the columns represent treatments like “Formulation 1 or F1, F2, F3 … Fn” for each formulation, being studied numbered 1 to nth. The rows represent the number of trials done to study each formulation, usually a minimum of three trials is required for proper statistical tests to enhance accuracy of results.

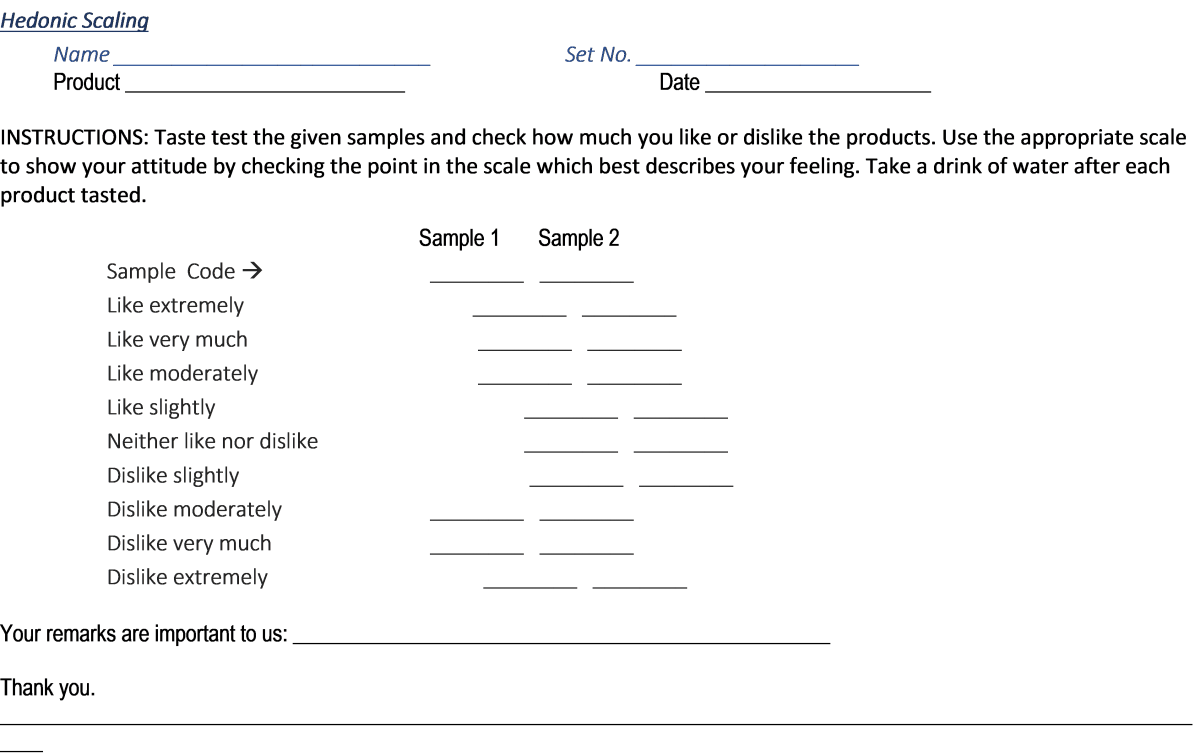

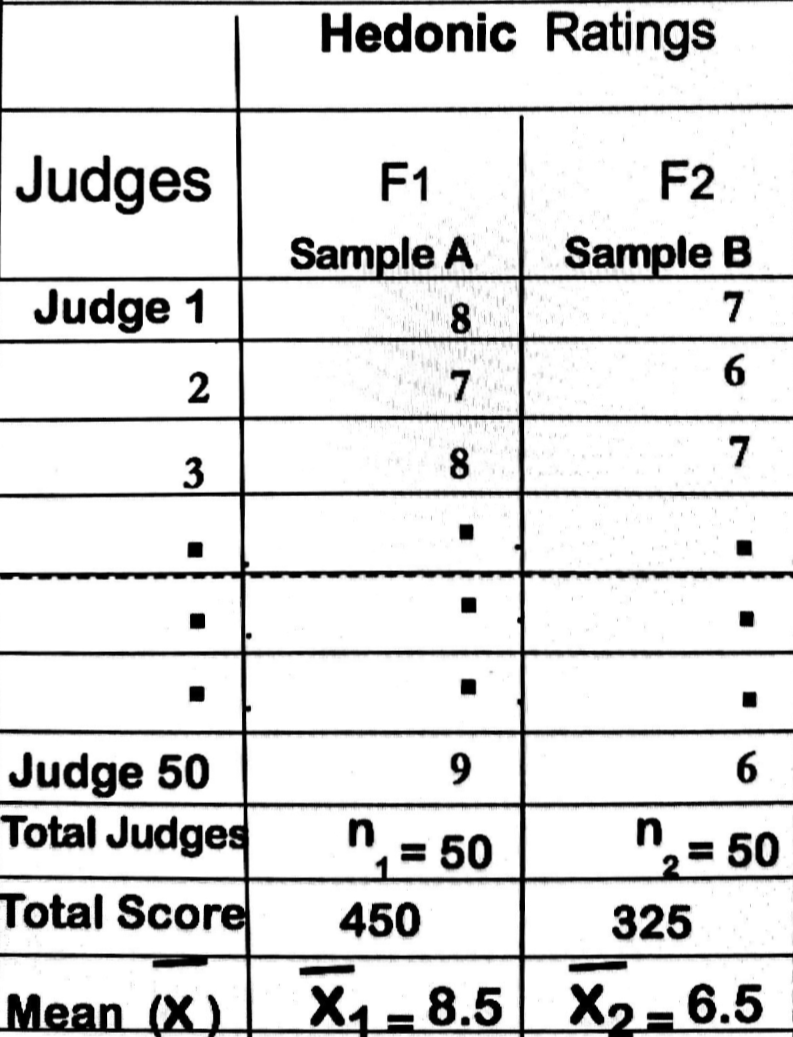

Problem-solving 4 – “Design of Experiment” or “Matrix Design” format is shown in Figure 6a and 6b. To be able to choose the most likely candidate for further development, several tests are done on major characteristics such as physical, chemical, and sensory measurements. The final decision on the choice of product formulation is determined through sensory evaluation tests that focus on food product characteristics desired by customers identified during the problem definition stage (D1- Define the Problem). Finally, when one or two candidate formulations are chosen, these are subjected to repeated process tests for repeatability and reproducibility leading to development of product and process standards or specifications. At these stages, various types of problem-solving tools are utilized, and one of the most important among them is the measure of consumer acceptability using the ‘Hedonic Rating Scale” shown in Figure 7. Although few would consider this as a problem-solving tool, still the scoresheet was developed based on an experimental design where data collected can be analysed statistically. It is also a means to solve the problem of knowing what the consumers actually want through their specified average “acceptability level”. Between two samples, a statistical test for significant difference can be done using the t-test for simple difference. Should there be three or more formulations to choose from, the Analysis of Variance can be utilised (Gatchalian and Brannan, 2011).

Fig. 6a. Matrix design in problem-solving

Fig. 6b, Sample complete block experimental design

Problem-solving 5 – Hedonic Rating Scale for Acceptability At this point, reference is again made to Fig. 1, where “consumer survey” mainly for product acceptability level determination, is seen next to the last stage in product development. The consumer survey should be done before commercial production. Without this measure, a new product cannot be assumed to have a high level of acceptability in the market. In fact, this is considered one of the major reasons why findings show that about 75% of food product innovation fails to be sustained after market launch (Gatchalian, 2018(b); Menrad 2007). In general practice before product launch, an average hedonic score of 8.5 (between like very much and like extremely) almost always would guarantee a sustainable product life in the marketplace provided all other factors related to Quality Assurance and Marketing and Sales remain in place.

Fig. 7a. Sample hedonic rating scale scoresheet for consumer acceptability test

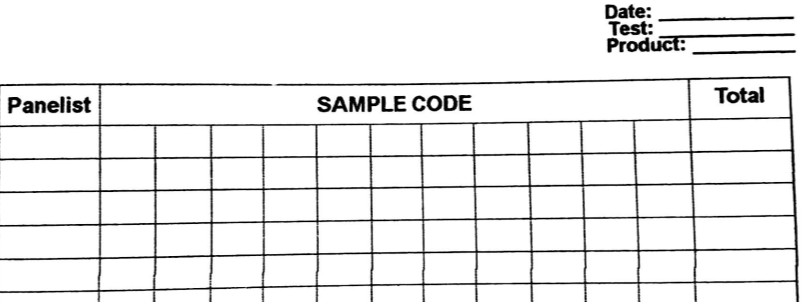

D3 – Develop data collection approaches

In all stages of problem-solving associated with innovation, proper data collection and treatment are both imperative. It is expected that from the start of any problem-solving activities, documentation is well planned and utilised. Thus, for data collected at the D3 (Data collection) stage, it is most important that “summary sheets” (Fig. 8a) which is eventually filled-up with properly collected data (Fig 8b) have been designed in D2 (Design a Plan). These are necessary for use in statistical analysis to ensure accuracy and repeatability of results, characteristics of a scientifically organised problem-solving activities.

Problem-solving 6. “Summary Table” or “Data Sheet” in problem-solving are important tools for initiating analysis of collected data or survey results. Fig. 8a shows a sample of a “summary table” useful in sensory evaluation tests or in consumer surveys. This is oftentimes called “dummy table” because it only contains row and column labels and no data. Before the start of an experiment or survey, it is good to prepare a table where one intends to record collected data.

Fig. 8a. Summary table of raw data from hedonic ratings for acceptability

D4 – Describe results of collected data

Authorities like Winger and Wall (2006) commented that most food innovation activities are less scientific compared with those in the areas of biotechnology, electronics, etc. Some reasons for this were attributed to: (a) lack of scientific approaches being utilised in the field or (b) the absence of capability to measure and quantify human responses to stimuli like food. To date, much work had been published on sensory quality measurement. However, there may have been little actual applications in food product innovation. This paper hopes to encourage more scientists involved with product development to engage in scientific approaches to collecting data, analysing and interpreting results statistically with highest level of confidence. Properly describing results in answer to the defined problem, making reliable conclusions and useful recommendations can make problem-solving activities a worthwhile endeavor in the innovation process.

Use of tested statistical methods for data analysis and interpretation are strongly encouraged. More detailed information about statistical approaches in sensory evaluation can be obtained from Gatchalian and Brannan (2011). An example of data collected from the hedonic rating scale scoresheets used in consumer survey is shown in Figure 8b. The survey determines the level of acceptability of two candidate products for possible commercial production. The final judge of a food product is the consumer and their acceptability level, determined during the consumer survey, and pinpoints which product is ready for commercial production.

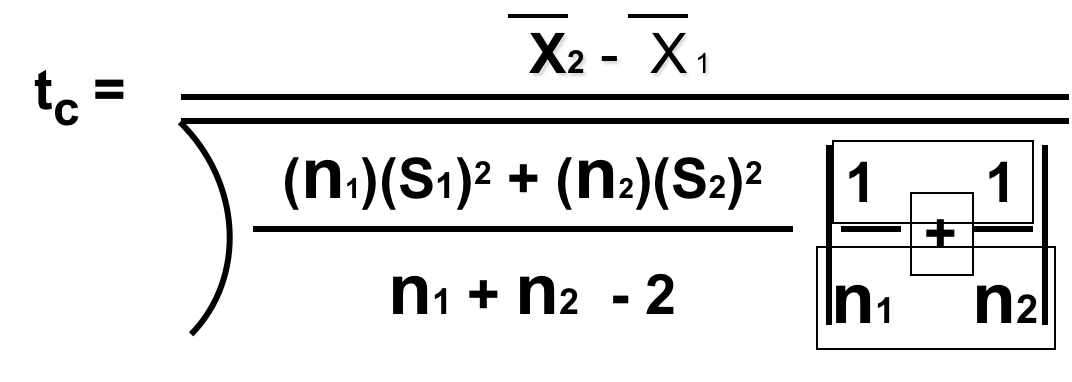

Problem-solving 7 – Testing of Hypothesis is used to determine if there is a significant difference in average acceptability scores between the two candidate products slated for commercial production. This can be done through the use of a simple statistical test of hypothesis known as the “t-test for significant difference.” Analysis of collected data from Fig. 8b starts with the statement of: null hypothesis (Ho), alternative hypothesis (Ha) and level of significance (alpha=5%). Use of t-test to determine significant difference between the two sample means can be done following the formula below.

Set up the statistical hypothesis for the hedonic rating scale test conducted in a survey:

|

Ho: m1 = m2 |

Samples X1 and X2 are equal in acceptability. level |

|

Ha: m1 ¹ m2 |

Samples are significantly different from each other |

|

a-level |

= .05 probability or 5% level of significance |

Apply the formula for tc or t computed

where:

n1 = number of individuals judging Product A or (X1)

n2 = number of individuals judging Product B or (X2 )

S12 = variance for Product A (Sample X1)

S22 = variance for Product B (Sample X2 )

When level of Significance is 5% then level of Confidence in the results would be 95% enabling the researcher-problem-solver to make conclusions about his findings with highest confidence. For this example, Sample A ( X1 ) from Formulation A obtained a significantly high “acceptability average score of 8.5” (between like very much and like extremely in the scoresheet in Fig. 7a) versus Sample B ( X2 ) from Formulation B which received an acceptability average score of only 6.5 (between like and Like moderately). Applying the tc formula above, on data collected, showed that computed tc = 2.15 is greater than ta at 5% level of significance (1.996 for degree of freedom of 98). This implies that Sample A has definitely a higher acceptability level than Sample B giving the assurance that Sample A would have a good chance to compete and remain in the market where the targeted consumers are located. This assumes that all other factors affecting product acceptability remain the same through time.

D5 – Derive conclusions and recommendations

Based on outputs obtained from “D4 - Describe Results”, reliable conclusions can be drawn. From the consumer survey results, it can be concluded with confidence that Product A (Sample A) has a significantly higher acceptability level (average score of 8.5) compared with Product B (Sample B with average score of 6.5). Thus, the decision to start commercial production of Product A can be confirmed with supporting evidences including favourable remarks obtained from comments by the consumer survey respondents in their hedonic rating scale scoresheets. Without the survey, it would be impossible to conclude with certainty that Product A has a higher acceptability level than Product B since the opinion of targeted consumers was not solicited through proper use of “acceptability tests”. With conclusive results, recommendations pertaining to the commercial production of selected product with process specifications can be refined and finalised.

D6 – Develop report and action plan

All the major activities conducted to initiate product innovation (starting with D1-Define the problem), proceeding to product development and final consumer tests should be reported to management in a one page “executive summary” following the sequence of the MMG’s 6Ds. All supporting data (i.e. sample scoresheet, computations, etc) should be attached as Exhibit A, Exhibit B, and so on. This way the decision-makers can easily understand the whole process that led to proposal of the new product for commercial production. Action plans should indicate the first steps to be taken to initiate the market launching.

Summary

To remain competitive in the food product market arena, it is imperative that the food manufacturing company engage in continuous scientific innovation activities. It is known that innovation is actually a form of problem-solving and it would be of great advantage to have a working knowledge of the basic problem-solving approaches. Among the many available approaches, the following are some of the simplest and most practical problem-solving tools generally employed in food product innovation and these are as follows: (1) brainstorming; (2) affinity diagram; (3) checklist screening; (4) experimental design; (5) hedonic rating scale; (6) summary table; and (7) test of hypothesis. These problem-solving tools and techniques facilitate decision-making with highest level of confidence, a capability much needed in food product innovation.

References

Gatchalian, M.M. 2018 (a). Innovation Management in Food Product Development. Food Pacific Manufacturing Journal. Vol. XVIII NO. 2, (March ) ISSN 1608-7100. Ringier Trade Media Ltd. Hong Kong

Gatchalian, M.M. 2018(b). Innovation management: Enhancing competitiveness through organized innovation activities. Food Pacific Manufacturing Journal. Vol. XVIII, No. 4, (July). ISSN 1608-7100. Ringier Trade Media Ltd. Hong Kong

Gatchalian, M. M. and Brannan, Grace D. 2011. Sensory Quality Measurement: Statistical Analysis of Human Responses, 3rd edition. Quality Partners Company, Ltd. 283pp. Quezon City Philippines; ISBN 978-971-691-921-9. E: qpcl.gatch@gmail.com

Harrington, James H. 2015. Innovative Process. Harrington Institute, A Division of Harrington Group, International, U.S.A

Menrad, K. 2007. Traditional products and the economic impact of innovation. Wissenschaffs, Zentrum, Straubing Germany.

Winger, R. and Wall. G. 2006. Food Product Innovation: Background Paper. Agricultural and Food Engineering Working Document. Rome, Italy

iConnectHub

iConnectHub

Login/Register

Login/Register Supplier Login

Supplier Login