Machine shops seek to produce a specific number of parts of a true quality, in a certain amount of time, at a fixed cost. Consistently achieving those goals involves controlling a myriad of factors including cutting parameters, tool cost and changeover times, machine tool utilisation, workpiece handling expense and material and labour costs.

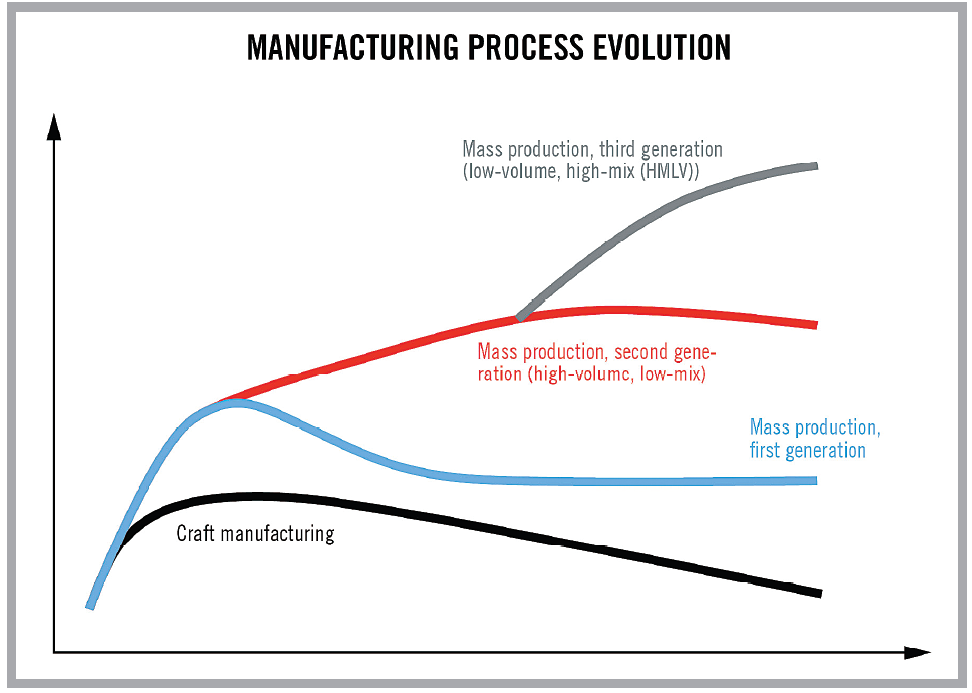

Production economics is the art and science of balancing process factors to achieve desired results. Over more than two centuries of machining history, the elements of production economics have multiplied in number. Manufacturing first evolved from craft-level single-item output to mass production of standardised parts using machine tools. Improving manufacturing methods brought about a second generation of mass production featuring production lines and output of increasingly greater numbers of identical parts: a high volume, low product mix (HVLM) scenario. Then CNC machines and robots fostered a third generation of mass production efficiency. Most recently, digital technology applied in programming, machine tool controls and workpiece handling systems is facilitating a fourth generation of manufacturing production, known as Industry 4.0, that enables cost-efficient, high-mix low-volume (HMLV) production.

To effectively accomplish the shift from HVLM to HMLV production it is crucial that manufacturers recognise the changing and growing realities of production economics and take advantage of the information and technology available to analyse their operations and meet their goals. A key element of the transformation involves abandoning overly simplistic beliefs and practices and uncovering hidden costs that can undermine attempts to maximise productivity.

High volume, low mix, simple economics

Standardised machining processes were developed in the 19th century to speed production of identical products with interchangeable parts. Automotive manufacturing refined this HVLM approach to a maximum degree, establishing transfer lines and other methods to make hundreds of thousands or millions of the same part over and over for years.

The long-term nature of HVLM production allows manufacturers to fine-tune multiple process factors for maximum output, consistency and low cost. Ancillary technology including tool and pallet changers and robots further minimise variability. It is assumed that the operation runs perfectly and provides 100 percent yield with predictable costs,no unplanned idle times, no rejects, no rework and no secondary operations such as deburring.

One assumption is that tool cost is typically about three percent of total production cost. The three percent number is a convenient benchmark but is rarely valid. Workpiece material machining characteristics, for example, have great effect; a switch from steel to titanium in machining a part can increase tool usage by a factor of five. The three percent proportion becomes 15 percent, all else being equal.

Focusing solely on tool engagement time results in neglect of other factors such as idle times for tool changing.This approach is effectively hiding from reality. Manufacturers should understand that machining time, setup time, tool change time, loading and unloading, and other factors affect and interfere with each other.

A simplified example of unanticipated interaction of process factors involves a shop machining a part that requires two minutes cutting time and a total of two minutes to load and unload the workpiece. Indexing the tool consumes a minute, and tool life is five workpieces, making tool indexing time 0.20 minutes per part. Because every part requires 4.2 minutes processing time, output is slightly more than 14 workpieces per hour. Each tool costs 15 euro, and tool life of five workpieces dictates that 2.8 tools (42 euro) are needed to produce 14 workpieces. Machine cost is 50 euro per hour. Altogether, production cost for 14 workpieces in one hour is 92 euro.

Then, attempting to speed output and productivity, the shop increases cutting speed by 10 percent. That reduces cutting time by 10 percent (to 1.8 minutes) but also cuts tool life roughly in half, meaning that one cutting edge will produce only two and half workpieces before indexing is required. Tool indexing time is still one minute and workpiece load/unload two minutes. Production time for one workpiece remains 4.2 minutes (1.8 minutes cutting, 2 minutes workpiece manipulation, and 0.4 minutes tool indexing) or 14 workpieces per hour. The machine and tool costs are the same, but now 5.6 tools (84 euro tool cost) are required to run for an hour. Despite the effort to speed output, production time for 14 workpieces is the same and cost rises from 92 euro to 134 euro.

In this case, increasing cutting speed does not make the operation more productive. Changing cutting time affects other factors in the machining system, in this example tool life and tool indexing time. Accordingly, a shop must carefully consider the full consequences of process changes.

Another form of hidden cost involves execution of steps in the process. In many machine shops the time spent indexing inserts, for example, is a textbook case of hidden cost. The designated time to index an insert may be one minute. However, when measured in actuality on the shop floor, it can be two, three or ten minutes, a difference of 60 to 600 seconds

High mix, low volume, complex considerations

More recently, global competition is prompting manufacturers to create different versions of their products to match the needs of smaller subsets of users. Advanced computing technology permits rapid change of part designs and machining programs and also enables easy tracking of product variations and inventory. The result has been a shift to higher mix, lower volume (HMLV) production scenarios. Today, that approach has been developed sufficiently to enable efficient manufacture of single-digit or even single-item production runs.

The extended time horizon of HVLM production permits deliberate planning and fine-tuning of process factors. Planning is different in HMLV situations. Computerised engineering and inventory technologies support rapid changes in product type and output, but consequently the HMLV planning process must be complex and reactive. An order for ten parts may be followed by two, five, or even single-item lots of different parts. Workpiece materials may change from steel to aluminium to titanium, and part geometries from simple to complex. There is not enough time available to determine tool life through trials.

To manage tool life in HMLV situations, a workshop typically makes a conservative guess regarding a tool´s projected life and, to be safe, employs a new tool for each run, discarding it well before it reaches its full productive lifespan. Cutting time is only one factor in the overall picture. In HMLV production, the time required to manipulate different workpieces and fixtures, change tools and index inserts will often be longer than the actual cutting time. Tooling, machine tool, idle time, direct labour and workpiece material factors may contain hidden costs. The most recent approach to production economics takes into account tool and workpiece material costs, equipment and production cost, equipment cost during downtime and salary and maintenance costs.