transfluid simplifies complex tube processing with an automatic tool change system

The transfluid machine permits bending radii of 1 x D and more for tubes with diameters up to 127 mm while reducing wall thicknesses from 2 mm to 1.5 mm.

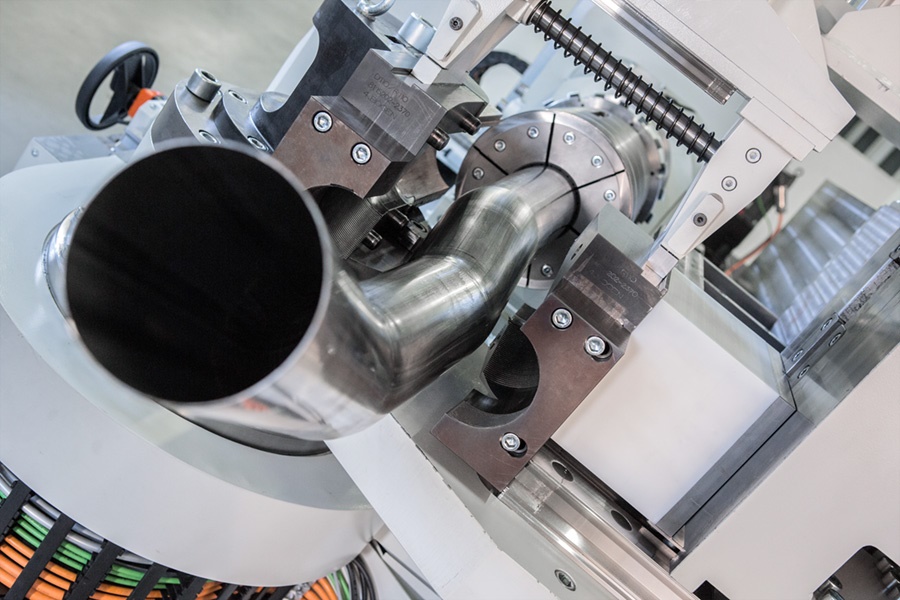

Continually faster and more adaptable: Bending of tubes with diameters of up to 127 mm is growing continually more demanding, while the subsequent costs are to approximate zero. "It isn't only about implementing technical efficiency in processes or machines anymore," says Stefanie Flaeper, managing director at transfluid. "Most of all, the increased demands to new products must be implemented here. No matter the time efficiency and precision, the solution should, of course, be controllable." The specialists from North Rhine-Westphalian Schmallenberg have developed their tube bending machine to bend DB 40120-CNC-VE for this. It permits bending radii of 1 x D at very low wall thicknesses in such tubes.

More effective with transfluid sequence control

In the scope of a current project, the setup of this special bending system has been implemented fully electrically. All movement axes are optimally synchronised by the special transfluid sequence control or can be programmed controlled against each other. Additionally, it is possible to easily optimise the process via this sequence control, which effectively improves product-specific cycle times.

Another strong point is simple operation. All parameters can be taken from the CAD and the corresponding form spanners can be called automatically as required. The transfluid engineers have implemented reduction of the subsequent costs by an automatic spanner change system. The time frame for tool change is comparable to that of a radius change.

Changing the spanners up to eight times

The new DB 40120-CNC-VE has two tool levels. It is able to change the spanners eight times, so that each tube can be bent even in highly complex geometries. This form of tool equipment is particularly efficient, reducing subsequent costs to a minimum. "In particular because the diameters are relatively similar and radii are very narrow at 1 x D, only the course geometries really change in new products. This means that only new spanning elements need to be used," explains Stefanie Flaeper. To implement the narrow radii at a relatively low wall thickness, the new pipe bending machine has an additional pusher device that can controlledly guide even the last bend at short remaining lengths.

The transfluid machine permits bending radii of 1 x D and more for tubes with diameters up to 127 mm while reducing wall thicknesses from 2 mm to 1.5 mm.

Air Jordan Trainer Essential